Ford Mustang (1999-2004) Service Manual: Electronic Vibration Analyzer (EVA)

The EVA is a hand-held electronic diagnostic tool which will assist in locating the source of unacceptable vibrations. The vibration sensor can be remotely mounted anywhere in the vehicle for testing purposes. The unit displays the three most common vibration frequencies and their corresponding amplitudes simultaneously. A bar graph provides a visual reference of the relative signal strength (amplitude) of each vibration being displayed and its relative G force. The keypad is arranged to make the EVA simple to program and use. Some of the functions include the ability to average readings as well as record, play back and freeze readings. The EVA has a strobe balancing function that can be used to detect imbalance on rotating components such as a driveshaft or engine accessories.

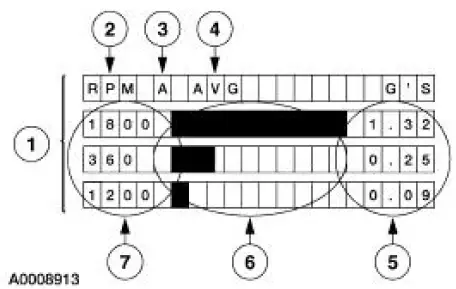

| Item | Description |

| 1 | EVA screen |

| 2 | Frequency mode displayed in rpm or Hz |

| 3 | Active sensor input (A or B) |

| 4 | Current active mode |

| 5 | G force indicators or the strongest frequencies in descending strength of each vibration |

| 6 | Strength of each vibration |

| 7 | Frequency in rpm/Hz of each vibration |

The EVA allows for a systematic collection of information that is necessary to accurately diagnose and repair NVH problems. For the best results, carry out the test as follows:

a. Test drive the vehicle with the vibration sensor inside the vehicle.

b. Place the sensor in the vehicle according to feel.

- If the condition is felt through the steering wheel, the source is most likely in the front of the vehicle.

- A vibration that is felt in the seat or floor only will most likely be found in the driveline, drive axle or rear wheels and tires.

c. Record the readings. Also note when the condition begins, when it reaches maximum intensity, and if it tends to diminish above/below a certain speed.

- Frequencies should be read in the "average" mode.

- Frequencies have a range of plus or minus 2. A reading of 10 Hz can be displayed as an 8 Hz through 12 Hz.

d. Place the vibration sensor on or near the suspect area outside the vehicle.

e. Continue the road test, driving the vehicle at the speed the symptom occurs, and take another reading.

f. Compare the readings.

- A match in frequency indicates the problem component or area.

- An unmatched test could indicate the concern is caused by the engine, torque converter, or engine accessory. Use the EVA in the rpm mode and check if concern is rpm related.

- Example: A vibration is felt in the seat. Place the sensor on the console. Record the readings. Place the vibration sensor on the rear axle. Compare the readings. If the frequencies are the same, the axle is the problem component.

Noise, Vibration and Harshness (NVH) (Description and Operation)

Noise, Vibration and Harshness (NVH) (Description and Operation)

Noise is any undesirable sound, usually unpleasant in nature. Vibration is

any motion, shaking or

trembling, that can be felt or seen when an object moves back and forth or up

and down. Harshness is ...

Vibrate Software

Vibrate Software

Vibrate Software (Rotunda tool number 215-00003) is a diagnostic aid which

will assist in pinpointing

the source of unacceptable vibrations. The engine's crankshaft is the point of

reference for vib ...

Other materials:

Glass, Frames and Mechanisms

WINDOW REGULATOR ELECTRIC DRIVE

CURRENT DRAW

General Specifications

Torque Specifications

...

Car2U® home automation system

WARNING: Make sure that the garage door and security device

are free from obstruction when you are programming. Do not

program the system with the vehicle in the garage.

WARNING: Do not use the system with any garage door opener

that does not have the safety s ...

Removal

Convertible

1. For removal of the back window glass, refer to Section.

Coupe

WARNING: To prevent glass splinters from entering eyes or

cutting hands, wear safety

glasses and heavy gloves when cutting glass from the vehicle.

2. Remove the roof side ...