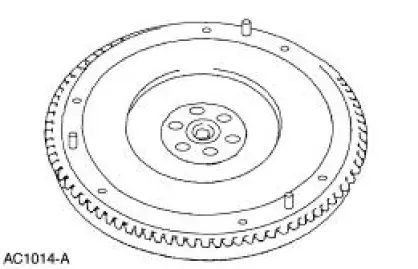

Ford Mustang (1999-2004) Service Manual: Flywheel Ring Gear

Removal

1. Remove the flywheel.

2. WARNING: This procedure should be carried out only by a correctly equipped and experienced acetylene torch operator. Tongs must be used or asbestos gloves worn when handling the heated flywheel ring gear. Failure to follow these instructions can result in personal injury.

CAUTION: Tap the flywheel ring gear evenly to prevent binding.

Remove the flywheel ring gear from the flywheel.

- Evenly heat the flywheel ring gear with an acetylene torch and use a brass drift to drive the flywheel ring gear off the flywheel.

Installation

1. WARNING: This procedure should be carried out only by a properly equipped and experienced acetylene torch operator. Tongs must be used or asbestos gloves worn when handling the heated flywheel ring gear. Failure to follow these instructions can result in personal injury.

CAUTION: Do not heat the flywheel ring gear beyond 261C (500F). Use heatindicating crayons to prevent overheating.

CAUTION: Keep the torch moving to prevent hot spots.

Evenly heat the flywheel ring gear with an acetylene torch.

- Install the flywheel ring gear with the bevel on the flywheel ring gear facing the rear of the flywheel.

- Use a brass drift to tap the flywheel ring gear into position, reheat as necessary.

2. Install the flywheel.

Pilot Bearing

Pilot Bearing

Special Tool(s)

Puller with Slide Hammer

308-001 (T58L-101-B)

1. Remove the clutch disc and the clutch pressure plate. For additional

information, refer to Disc

and Pressure Plate-3.8 ...

Clutch Controls

Clutch Controls

General Specifications

Torque Specifications

...

Other materials:

Charging System (Description and Operation)

The charging system is a negative ground system consisting of the

following:

generator

internal voltage regulator

charging system warning indicator

storage battery

necessary wiring and cables

The generator is belt-driven by the engine ...

Removal

WARNING: The restraints control module (RCM) orientation is critical

for proper system

operation. If a vehicle equipped with an air bag supplemental restraint system

(SRS) has been

involved in a collision in which the center tunnel area has been damaged,

in ...

Instrument Panel - Center Finish Panel

Removal and Installation

All vehicles

1. Disconnect the battery ground cable. For additional information,

refer to Section.

Vehicles with automatic transmission

2. Place the selector lever in the 1 position.

Vehicles with manual transmission

3. ...