Ford Mustang (1999-2004) Service Manual: Ignition Coil

Material

| Item | Specification |

| Silicone Brake Caliper Grease and Dielectric Compound D7AZ-19A331-A or equivalent | ESE-M1C171- A |

Removal and Installation

1. Disconnect the battery ground cable (14301). For additional information, refer to Section.

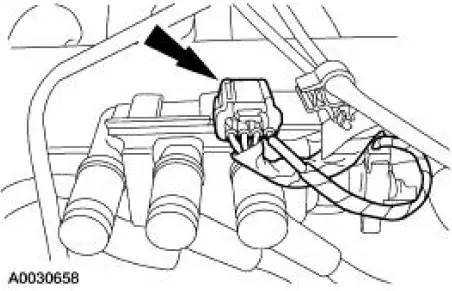

2. Disconnect the ignition coil electrical connector.

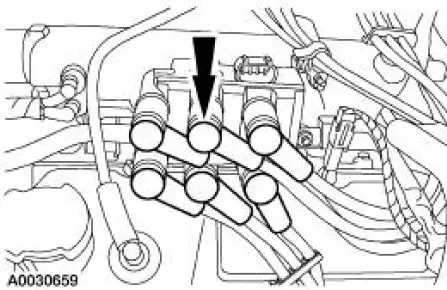

3. CAUTION: Spark plug wires (12286) must be connected to the correct ignition coil terminal. Mark spark plug wire locations before removing them.

Twist while pulling upward to disconnect the spark plug wires.

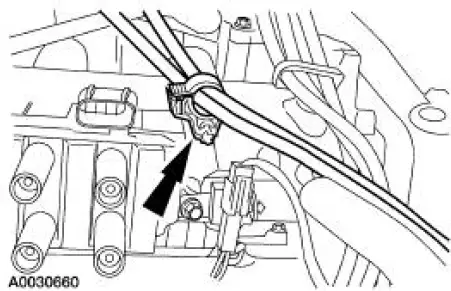

4. Disconnect the accelerator cable retaining clamp from the ignition coil stud bolt.

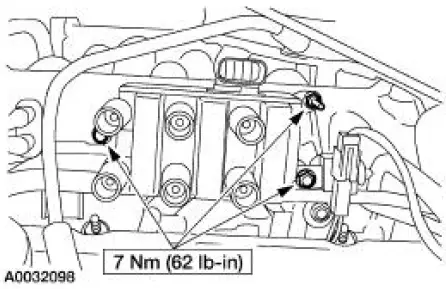

5. Remove the bolts and the ignition coil (12029).

6. NOTE: Apply silicone brake caliper grease and dielectric compound to the inside of the spark plug wire coil boot.

NOTE: Be sure to reinstall the radio ignition interference capacitor (18801) under the correct mounting bolt.

To install, reverse the removal procedure.

Engine Ignition (Description and Operation)

Engine Ignition (Description and Operation)

The ignition coil (12029), which is mounted on the upper intake manifold, can

be described as a coil

pack containing three separate coil units. Each coil unit is individually

controlled by the power ...

Spark Plug Wire

Spark Plug Wire

Special Tool(s)

Remover, Spark Plug Wire

303-106 (T74P-6666A)

Material

Item

Specification

Silicone Brake Caliper Grease

and Dielectric Compound

D7AZ-19A331-A or equiva ...

Other materials:

Fuel Charging Wiring Harness

Removal and Installation

WARNING: Do not smoke or carry lighted tobacco or open flame of any

type when

working on or near any fuel related components. Highly flammable mixtures are

always present

and may ignite. Failure to follow these instructions may resul ...

Valve Stem to Valve Guide Clearance

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

Clearance Gauge, Valve Guide

303-004 (TOOL-6505-E) or

equivalent

NOTE: Valve stem diameter must be within specifications before

checkin ...

Fuel Charging And Controls

The fuel injection supply manifold (9F792):

delivers fuel to the fuel injector.

receives fuel from the fuel supply line.

The throttle body (9E926):

controls air supply to the upper intake manifold (9424) by positioning

the throttle plate.

connects the ...