Ford Mustang (1999-2004) Service Manual: Input Shaft and Bearing

Special Tool(s)

|

Remover, Driver Pinion Bearing Cone 205-D002 (D79L-4621-A) or equivalent |

|

Installer, Drive Pinion Bearing Cone 205-011 (T57L-4621-B) |

|

Remover/Installer, Bearing Tube 308-024 (T75L-7025-B) |

Disassembly and Assembly

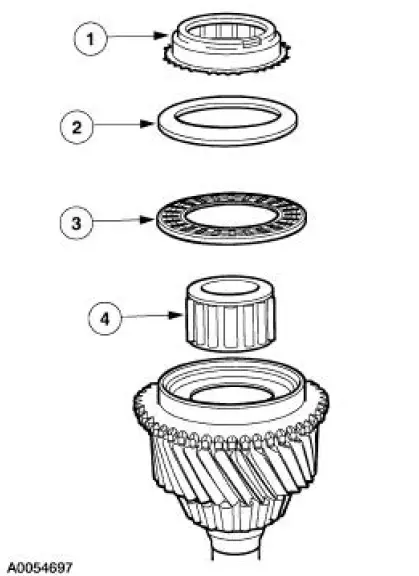

1. Disassemble the input shaft.

1. Remove the third/fourth synchronizer blocking ring.

2. Remove the input shaft thrust washer.

3. Remove the input shaft thrust bearing.

4. Remove the input shaft pocket bearing.

- Inspect all components for wear or damage. Install new components as necessary.

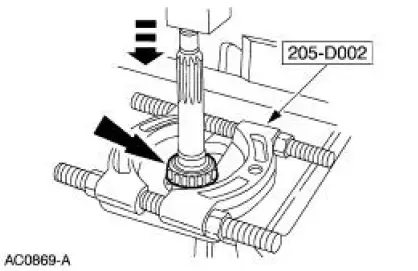

2. Using the special tool and a press, remove the input shaft front bearing assembly. Discard the bearing.

3. Inspect the input shaft and bearings for wear or damage. Install new components as necessary.

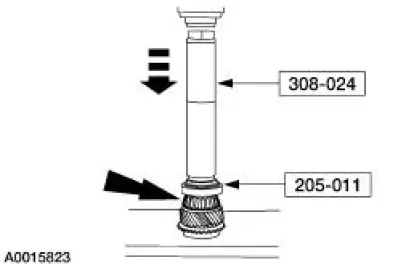

4. Using the special tools and a press, install the new input shaft front bearing.

5. Install the input shaft pocket bearing, the washer, input shaft bearing and the third/fourth synchronizer blocking ring.

- Lubricate the bearing and bearing race with petroleum jelly.

Transmission (Disassembly)

Transmission (Disassembly)

Special Tool(s)

Remover, Mainshaft Bearing

308-058 (T77J-7025-H)

Screw, Bearing Removal tube

308-092 (T84T-7025-B)

Holding Fixture, Transmission

307-003 (T57L- ...

Output Shaft

Output Shaft

Special Tool(s)

Remover, Drive Pinion Bearing

Cone

205-D002 (D79L-4621-A) or

equivalent

Installer, Drive Pinion Bearing

Cone

205-011 (T57L-4621-B)

...

Other materials:

Idle Air Control (IAC) Valve - Cobra

Removal and Installation

1. Disconnect the idle air control (IAC) valve electrical connector.

2. Remove the bolts, the IAC valve and the gasket.

3. NOTE: Install a new gasket if necessary.

To install, reverse the removal procedure. ...

Refueling

WARNING: Fuel vapor burns violently and a fuel fire can cause

severe injuries. To help avoid injuries to you and others:

• Read and follow all the instructions on the pump island.

• Turn off your engine when you are refueling.

• Do not smoke if you are n ...

Engine Ignition (Description and Operation)

Eight separate ignition coils:

are controlled by the powertrain control module (PCM).

are mounted directly above each spark plug.

are controlled by the powertrain control module for correct firing

sequence.

The spark plug:

changes the high vo ...