Ford Mustang (1999-2004) Service Manual: Inspection and Verification

1. Verify the customer concern by operating the wiper/washer system.

2. Visually inspect for obvious signs of mechanical and electrical damage.

Visual Inspection Chart

| Mechanical | Electrical |

|

|

3. If the concern remains after the inspection, connect the diagnostic tool to the data link connector (DLC) located beneath the instrument panel and select the vehicle to be tested from the diagnostic tool menu. If diagnostic tool does not communicate with the vehicle:

- Check that the program card is correctly installed.

- Check the connections to the vehicle.

- Check the ignition switch position.

4. If diagnostic tool still does not communicate with the vehicle, refer to the diagnostic tool manual.

5. Carry out the DATA LINK DIAGNOSTIC TEST. If diagnostic tool responds with:

- CKT914, CKT915 or CKT70 = ALL ECUS NO RESP/NOT EQUIP, refer to Section.

- NO RESPONSE/NOT EQUIPPED for GEM, go to Pinpoint Test A.

- SYSTEM PASSED, retrieve and record the continuous diagnostic trouble codes (DTCs), erase the continuous DTCs and carry out self-test diagnostics for the GEM.

6. If the DTCs retrieved are related to the concern, go to GEM Diagnostic Trouble Code (DTC) Index to continue diagnostics.

7. If no DTCs related to the concern are retrieved, proceed to Symptom Chart to continue diagnostics.

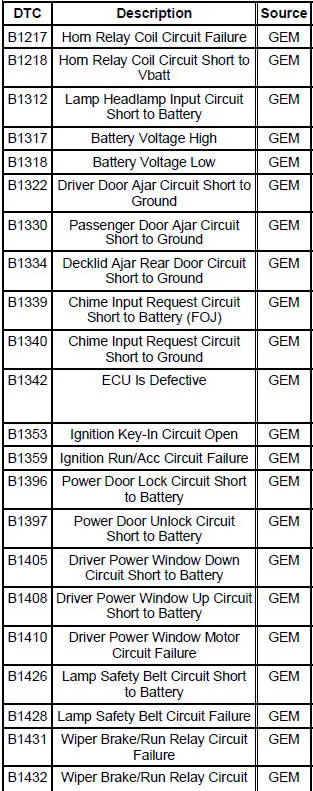

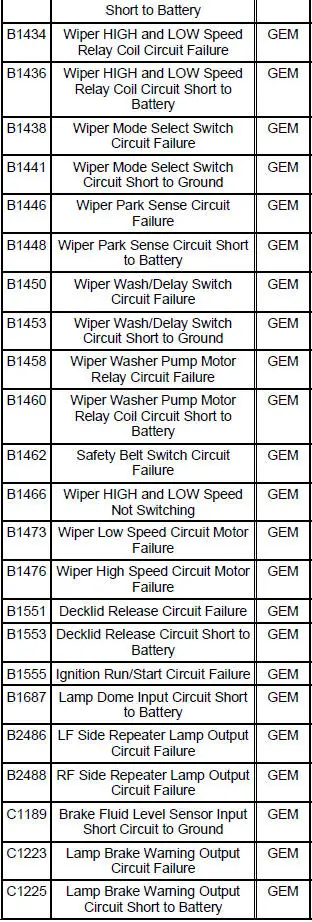

GEM Diagnostic Trouble Code (DTC) Index

Symptom Chart

| Condition | Possible Sources | Action |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Principles of Operation

Principles of Operation

Multifunction Wipers

The front wiper/washer feature controls the speed of the front

windshield wipers and the amount of

washer fluid sprayed on the front windshield when requested by the

cus ...

Pinpoint Tests

Pinpoint Tests

CAUTION: Before removing and installing the GEM or its connectors,

disconnect the

battery. Failure to follow this caution will result in the GEM storing many

erroneous DTCs and it

may exhibit errati ...

Other materials:

Removal

WARNING: Do not smoke or carry lighted tobacco or open flame of any

type when

working on or near any fuel related components. Highly flammable mixtures are

always present

and may be ignited. Failure to follow these instructions may result in personal

injury ...

Gearshift Lever and Boot

Material

Removal and Installation

1. Remove the gearshift lever knob.

2. Remove the console panel gearshift plate. Lift the gearshift lever boot

over the gearshift lever.

3. Remove the bolts and the shift lever.

4. Remove the screws and the inner shif ...

Manual transmission

Using the Clutch

Manual transmission vehicles have a starter interlock that prevents

starting the engine unless the clutch pedal is fully pressed.

To start the vehicle:

1. Make sure the parking brake is fully set.

2. Press the clutch pedal to the

floor, then ...