Ford Mustang (1999-2004) Service Manual: Refrigerant System Tests

Special Tool(s)

|

R-134a Manifold Gauge Set 176-R032A or equivalent |

1. Connect the R-134a Manifold Gauge Set. For additional information, refer to Manifold Gauge Set Connection in this section.

2. Adjust the climate controls for maximum cooling.

- Start the engine.

- Select MAX A/C operation.

- Set the blower motor speed to maximum.

3. Stabilize the in-vehicle temperature at 21-27C (70-80F).

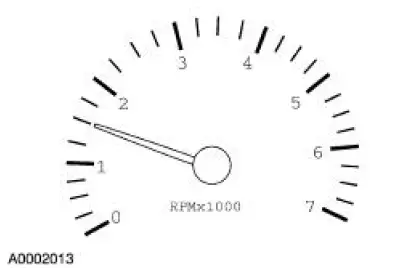

4. NOTE: When the ambient temperatures exceed 38C (100F), do not run the engine above normal idle speed.

Maintain the engine speed at 1,500 rpm.

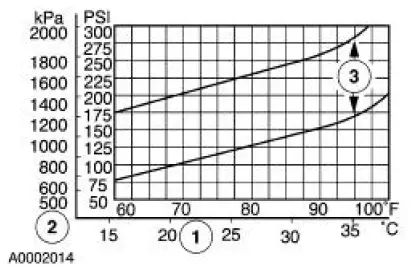

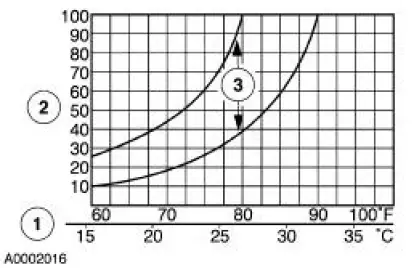

5. Determine the compressor discharge (high) pressure.

1. Record the ambient temperature.

2. Record the discharge (high) pressure.

3. NOTE: In ambient temperatures between 38-43C (100-110F), the system performance pressures will be the same as those for ambient temperatures shown on the chart in the 32-38C (90-100F) range.

The system performance is acceptable when the pressure reading falls between the upper and lower limits shown.

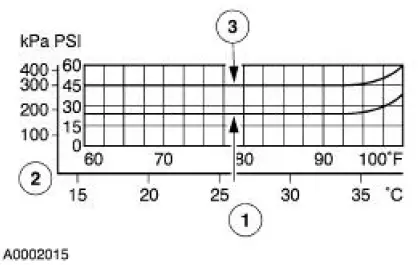

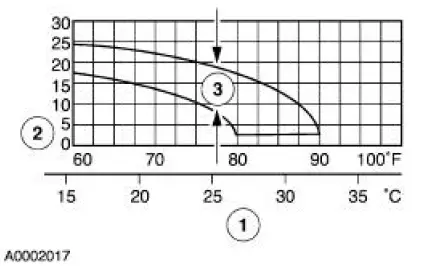

6. Determine the compressor suction (low) pressure.

1. Record the ambient temperature.

2. Record the suction (low) pressure.

3. NOTE: In ambient temperatures between 38-43C (100-110F), the system performance pressures will be the same as those for ambient temperatures shown on the chart in the 32-38C (90-100F) range.

The system performance is acceptable when the pressure reading falls between the upper and lower limits shown.

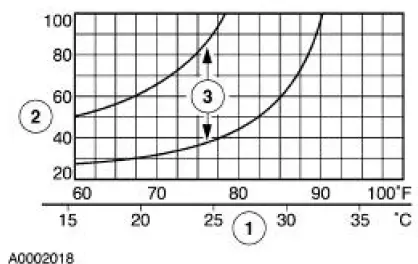

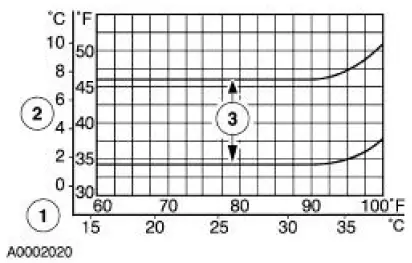

7. Determine the A/C clutch ON time.

1. Record the ambient temperature.

2. Record the A/C clutch ON time in seconds.

3. NOTE: When the ambient temperature is above 26C (80F), the A/C clutch may not cycle.

The system performance is acceptable when the recorded time falls between the upper and lower limits shown.

8. Determine the A/C clutch OFF time.

1. Record the ambient temperature.

2. Record the A/C clutch OFF time in seconds.

3. NOTE: When the ambient temperature is above 26C (80F), the A/C clutch may not cycle.

The system performance is acceptable when the recorded time falls between the upper and lower limits shown.

9. Determine the total A/C clutch cycle time.

1. Record the ambient temperature.

2. Record the time the A/C clutch is engaged plus the time it is disengaged (time ON plus time OFF).

3. NOTE: When the ambient temperature is above 26C (80F), the A/C clutch may not cycle.

The system performance is acceptable when the recorded time falls between the upper and lower limits shown.

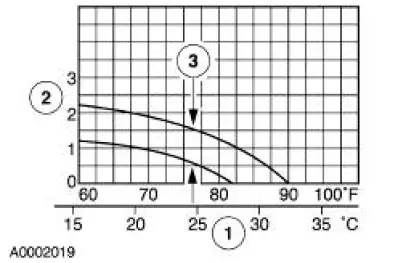

10. Determine the A/C clutch cycle rate per minute.

1. Record the ambient temperature.

2. Record the number of A/C clutch cycles occurring in one minute.

3. NOTE: When the ambient temperature is above 26C (80F), the A/C clutch may not cycle.

The system performance is acceptable when the recorded number of cycles falls between the upper and lower limits shown.

11. Determine the center A/C register discharge temperature.

1. Record the ambient temperature.

2. Record the center A/C register discharge temperature.

3. NOTE: In ambient temperatures between 38-43C (100-110F), the A/C register discharge temperatures will be the same as those for ambient temperatures shown on the chart in the 32-38C (90-100F) range.

The system performance is acceptable when the center A/C register discharge temperature falls between the upper and lower limits shown.

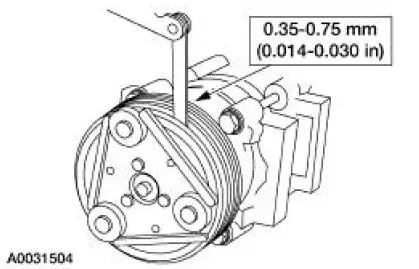

Air Conditioning (A/C) Clutch Air Gap Adjustment

1. Check the A/C clutch air gap at three equally-spaced places between the A/C clutch hub (2884) and the A/C clutch pulley (2E884).

2. Remove the A/C clutch. Add or remove spacers between the A/C clutch and the compressor shaft until clearance is within specification. For additional information, refer to Section.

Air Conditioning Line (Peanut) Fitting

Air Conditioning Line (Peanut) Fitting

Disconnect

1. CAUTION: Support the female fitting with a wrench to prevent the

tubes from

twisting.

Remove the nut from the peanut fitting.

2. Pull the peanut fitting apart.

3. CAUTION: Do not us ...

Manifold Gauge Set Connection

Manifold Gauge Set Connection

Special Tool(s)

R-134a Manifold Gauge Set

176-R032A or equivalent

1. Turn both valves on the R-134a Manifold Gauge Set clockwise to close the

low- and highpressure

hoses to the center ...

Other materials:

Compressor Manifold and Tube Assembly - 3.8L

Material

Item

Specification

PAG Refrigerant Compressor

Oil (R-134a Systems)

F7AZ-19589-DA (Motorcraft YN-

12-C)

WSH-M1C231-

B

Removal and Installation

NOTE: Installation of a new suction accumulator is not required when

repairing the ...

Material

Item

Specification

Threadlock and

Sealer

E0AZ-19554-AA

WSK-M2G351-A5 (type

II)

Shoulder Bolt Kit

F5ZZ-76539A04-A

-

NOTE: Before starting the adjustment process, inspect the top for damage,

make sure that the door

window glass ...

Input Shaft and Bearing

Special Tool(s)

Input Shaft Seal Replacer

308-220 (T94P-7025-AH)

Pinion Bearing Cone Remover

205-D002 (D79L-4621-A) or

Equivalent

Disassembly

1. Using the special tool and a press, remove the input bearing (7025).

2. Remove t ...