Ford Mustang (1999-2004) Service Manual: Climate Control System - General Information

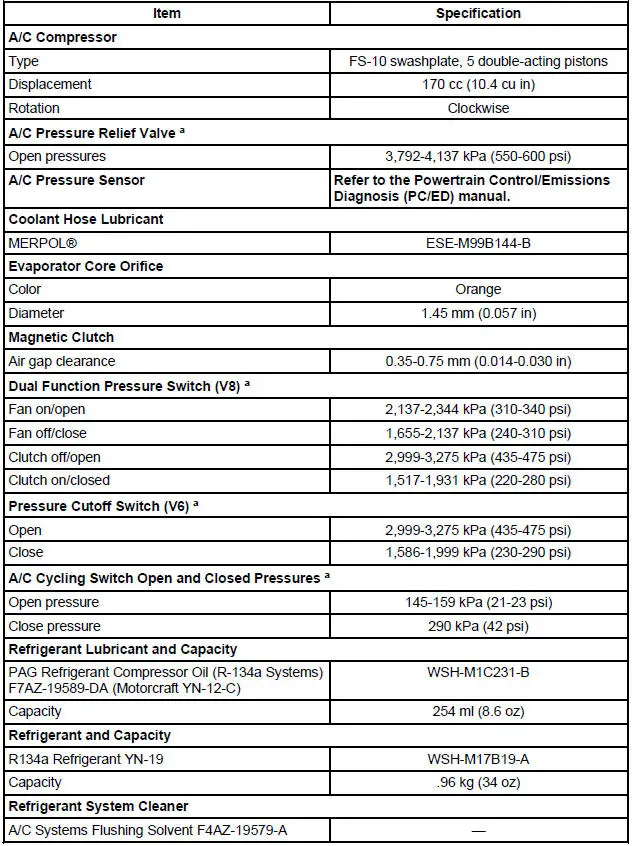

General Specifications

a - Manifold gauge set pressures may vary slightly depending on the distance between the service gauge port valve and the A/C pressure relief valve, the A/C cycling switch, the pressure cutoff switch (V6), and the dual function pressure switch (V8) location.

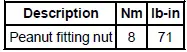

Torque Specifications

- Climate Control System (Description and Operation)

- Climate Control System (Diagnosis and Testing)

- Air Conditioning (A/C) System Check - Retail Procedure

- Spring Lock Coupling

- Heater Hose Coupling

- Air Conditioning Line (Peanut) Fitting

- Refrigerant System Tests

- Manifold Gauge Set Connection

- Electronic Leak Detection

- Tracer Dye Leak Detection

- Air Conditioning (A/C) System Flushing

- Air Conditioning (A/C) System Recovery, Evacuation and Charging

- Refrigerant System Filtering Following Air Conditioning (A/C) Component Installation

- Refrigerant Oil Adding

- Inspection and Assembly Requirements - Following an A/C Compressor Failure

- Refrigerant Identification Testing

- Contaminated Refrigerant Handling

- Vacuum Hose Repair - Mini-Tube

Climate Control System (Description and Operation)

Climate Control System (Description and Operation)

WARNING: To avoid accidental deployment and possible injury, the air

bag system

backup power supply must be depleted before repairing any climate control

components. To

deplete the backup power supp ...

Other materials:

Principles of Operation

NOTE: A new instrument cluster must be reconfigured. Refer to

Section.

The instrument cluster is a hybrid electronic cluster (HEC). The

instrument cluster uses both hardwired

and the standard corporate protocol (SCP) communication network to transmit

a ...

Valve Cover RH

Material

Item

Specification

Metal Surface Cleaner

F4AZ-19A536-RA or equivalent

WSE-M5B392-

A

Silicone Gasket and Sealant

F7AZ-19554-EA or equivalent

WSE-M4G323-

A4

PAG Refrigerant Compressor

Oil

F7AZ-19589-DA (Motorcraf ...

Rear Drive Axle and Differential

The axle housing assembly consists of a cast center section with two

steel tube assemblies and

a stamped differential housing cover (4033). The differential housing cover

uses silicone sealant

as a gasket.

The hypoid-design gearset consis ...