Ford Mustang (1999-2004) Service Manual: Air Conditioning Line (Peanut) Fitting

Disconnect

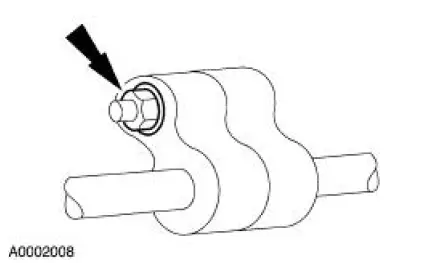

1. CAUTION: Support the female fitting with a wrench to prevent the tubes from twisting.

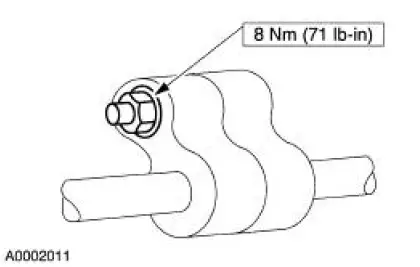

Remove the nut from the peanut fitting.

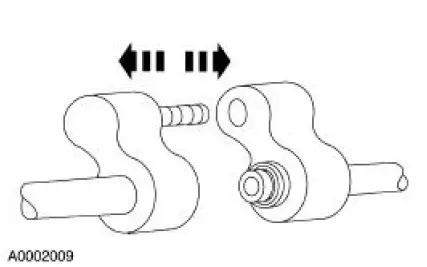

2. Pull the peanut fitting apart.

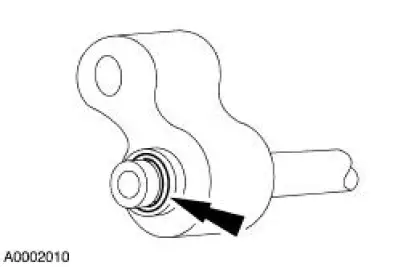

3. CAUTION: Do not use metal tools to remove the O-ring seal. They can cause axial scratches across the O-ring seal groove, resulting in refrigerant leaks.

Remove the O-ring seal with a non-metallic tool.

Connect

1. Clean all dirt or foreign material from the fittings.

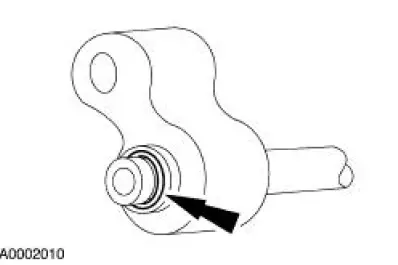

2. CAUTION: Use only the new O-ring seals. The use of any O-ring seals other than those specified in the Ford Master Parts Catalog may result in intermittent leakage during vehicle operation.

Install the O-ring seal.

- Lubricate the O-ring seal with PAG Refrigerant Compressor Oil (R-134a Systems) F7AZ- 19589-DA (Motorcraft YN-12-C) or equivalent meeting Ford specification WSH-M1C231- B.

3. Lubricate the inside of the fittings with PAG Refrigerant Compressor Oil (R-134a Systems) F7AZ-19589-DA (Motorcraft YN-12-C) or equivalent meeting Ford specification WSH-M1C231- B.

4. NOTE: When correctly assembled, the male and female fittings should be flush.

Assemble the male and female fittings together.

Heater Hose Coupling

Heater Hose Coupling

Special Tool(s)

Remover, Heater Hose Inlet

Tube

412-042 (T85T-18539-AH)

Disconnect Tool, Heater Hose

412-127

Material

Item

Specification

MERPOL

-

ESE-M ...

Refrigerant System Tests

Refrigerant System Tests

Special Tool(s)

R-134a Manifold Gauge Set

176-R032A or equivalent

1. Connect the R-134a Manifold Gauge Set. For additional information, refer

to Manifold Gauge

Set Connection in this ...

Other materials:

Trim Panel - Quarter, Coupe

Removal and Installation

1. Remove the upper quarter trim panel. For additional information,

refer to Trim Panel-Upper

Quarter in this section.

2. Remove the scuff plate.

3. Remove the pin-type retainers.

4. Lower the rear seat backrests.

5. Rem ...

Camshaft Roller Follower

Special Tool(s)

Compressor, Valve Spring

(Intake)

303-452 (T93P-6565-AR)

Compressor, Valve Spring

(Exhaust)

303-567 (T97P-6565-AH)

Removal

1. Remove the valve cover. For additional information, refer to Valve Cover

LH or Valv ...

Universal Garage Door Opener (If Equipped)

UNIVERSAL GARAGE DOOR OPENER

The appearance of your vehicle’s universal garage door opener will

vary according to your option package. Before programing, make sure

you identify which transmitter you have by comparing it to the graphics

below.

HomeLink®

Ca ...