Ford Mustang (1999-2004) Service Manual: Removal

1. Remove the differential assembly from the differential housing. For additional information, refer to Differential Case in this section.

2. CAUTION: Record the torque necessary to maintain rotation of the drive pinion gear through several revolutions prior to removing the pinion flange (4851).

Remove the pinion flange. For additional information, refer to Drive Pinion Flange and Drive Pinion Seal in this section.

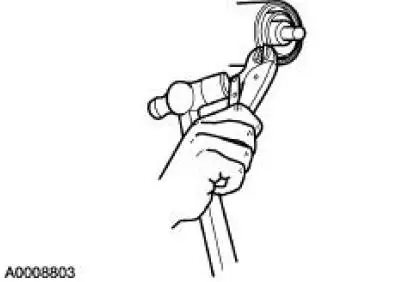

3. Force the rear axle drive pinion seal metal flange up. Install gripping pliers and strike with a hammer to remove the seal.

4. Remove the rear axle drive pinion shaft oil slinger (4670).

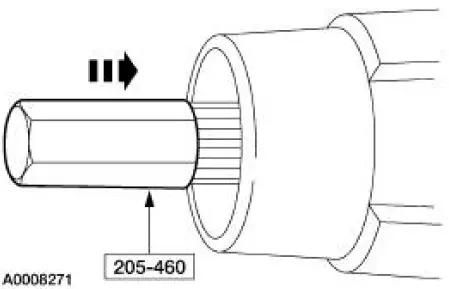

5. Using the special tool and a soft-faced hammer, drive the pinion assembly out of the outer differential pinion bearing (4621) and remove the drive pinion through the rear of the differential housing (4010).

6. Remove the outer differential pinion bearing.

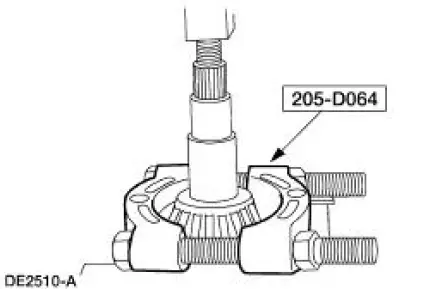

7. Remove and discard the collapsible spacer (4662).

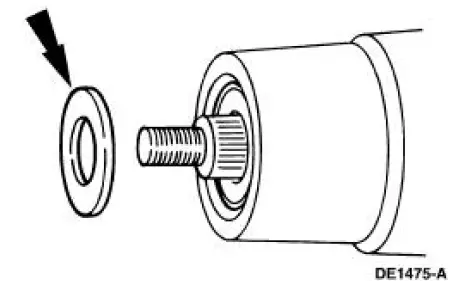

8. Using the special tool and a suitable press, remove the inner differential pinion bearing (4630).

9. NOTE: Do not remove the pinion bearing cups from the differential housing unless the cups are damaged.

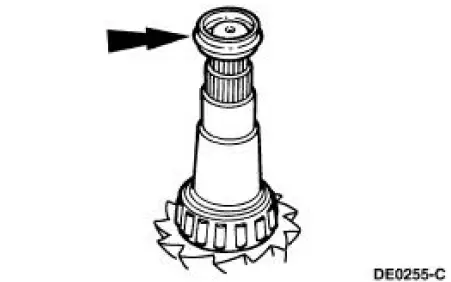

Using the special tools, remove the outer differential drive pinion bearing cup (4616).

10. Using the special tools, remove the inner rear axle pinion bearing cup (4628).

Drive Pinion

Drive Pinion

Special Tool(s)

Adapter for 205-S127

205-105 (T76P-4020-A3)

Adapter for 205-S127

205-109 (T76P-4020-A9)

Adapter for 205-S127

205-110 (T76P-4020-A10)

Adapter fo ...

Installation

Installation

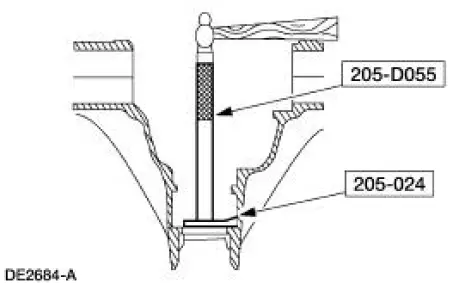

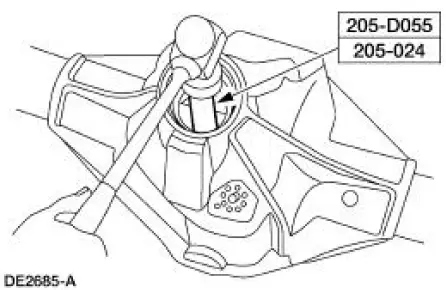

Using special tool 205-024

NOTE: This is the preferred method for installing the pinion bearing

cups. If necessary, proceed to

Using special tools 205-153, 205-024, 205-231, and 205-D055 in this proc ...

Other materials:

Climate Control System - General Information

General Specifications

a - Manifold gauge set pressures may vary slightly depending on the distance

between the service gauge port valve and the A/C pressure relief valve, the A/C

cycling switch, the pressure cutoff switch

(V6), and the dual function press ...

Rear View Mirrors

Torque Specifications

Rear View Mirrors

The rear view mirror system consists of the following components:

exterior rear view mirror

exterior rear view mirror control

exterior rear view mirror glass

exterior rear view mirror motor

interior ...

Link - Stabilizer Bar

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A

new part with

the same part number or an equivalent part must be installed, if i ...