Ford Mustang (1999-2004) Service Manual: Air Conditioning (Description and Operation)

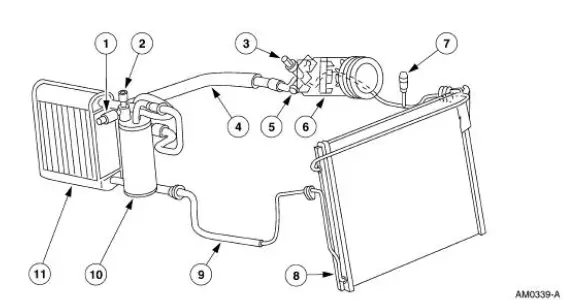

The A/C refrigerant system is a clutch cycling orifice tube type. The system components are:

- A/C compressor (19703)

- A/C clutch (2884)

- A/C condenser core (19712)

- A/C evaporator core (19860)

- suction accumulator (19C836)

- connecting refrigerant lines

The refrigeration system operation is controlled by the:

- A/C evaporator core orifice (19D990).

- A/C cycling switch (19E561).

- A/C compressor pressure relief valve (19D644).

- Refrigerant containment switch (3.8L) (19D594).

- Dual-function pressure switch (4.6L) (19D594).

The refrigerant system incorporates an A/C compressor controlled by an A/C cycling switch.

The A/C cycling switch senses A/C evaporator core pressure to control A/C compressor operation.

An A/C compressor pressure relief valve is installed in the A/C manifold and tube (19D734) to protect the refrigerant system against excessively high refrigerant pressures.

An evaporator core orifice is installed in the A/C evaporator core inlet tube to meter the liquid refrigerant into the A/C evaporator core.

A refrigerant containment switch is installed on 3.8L vehicles to cut-off A/C compressor operation in the event of abnormally high refrigerant system pressure.

A dual-function pressure switch is used on 4.6L vehicles for cooling fan control, and to cut-off A/C compressor operation in the event of abnormally high refrigerant system pressure.

Refrigeration System Components

- A/C Compressor and Clutch Assembly

- A/C Compressor Pressure Relief Valve

- Refrigerant Lines

- Evaporator Core Orifice

- Suction Accumulator

- Dual-Function Pressure Switch (4.6L)

- Spring Lock Coupling

Air Conditioning

Air Conditioning

General Specifications

Torque Specifications

...

A/C Compressor and Clutch Assembly

A/C Compressor and Clutch Assembly

NOTE: Internal A/C compressor components are not serviced separately.

The FS-10 A/C compressor

is serviced only as an assembly. The A/C clutch pulley, A/C clutch field coil

(19D798) and the shaft

...

Other materials:

Piston

Material

Item

Specification

Super Premium SAE 5W-20

Motor Oil

XO-5W20-QSP or equivalent

WSS-M2C153-

H

Disassembly

1. Press the piston pin out of the connecting rod and piston assembly.

2. Remove the connecting rod from the piston.

3. ...

Cooling Fan Motor and Shroud

Removal and Installation

1. Disconnect the battery ground cable.

2. Remove the degas bottle or coolant expansion tank. For additional

information, refer to Degas

Bottle-4.6L(2V) and 4.6L(4V) in this section.

3. Disconnect the cooling fan electrical connecto ...

Hydro-Boost Bleeding

1. NOTE: The Hydro-Boost power brake booster (2B560) is generally

self-bleeding, and the

following procedure will normally bleed the air from the power brake booster.

Normal operation

of the vehicle will further remove any additional trapped air.

Fill the p ...