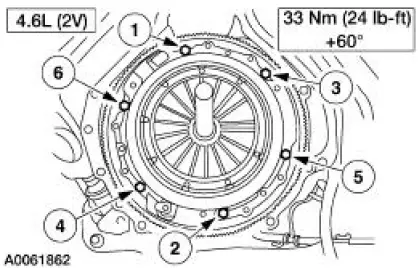

Ford Mustang (1999-2004) Service Manual: Disc and Pressure Plate - 3.8L and 4.6L (2V) Engines

Special Tool(s)

|

Clutch Aligner 308-020 (T74P-7137-K) |

Material

| Item | Specification |

| Premium Long Life Grease XG-1-C | ESA-M1C75-B |

1. Remove the transmission.

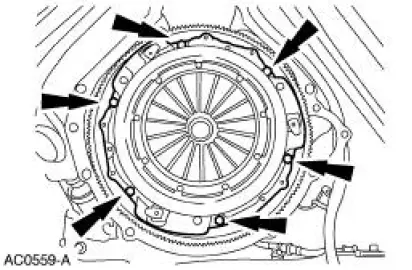

2. CAUTION: Loosen the bolts evenly to prevent clutch pressure plate damage.

NOTE: If the parts are to be reused, mark the clutch pressure plate and the flywheel.

Remove the bolts and remove the clutch pressure plate and the clutch disc.

Installation

NOTE: Clean the clutch pressure plate and flywheel with a commercial alcohol-based solvent so surfaces are free from oil film.

Do not use cleaners with a petroleum base. Do not immerse the clutch pressure plate in the solvent.

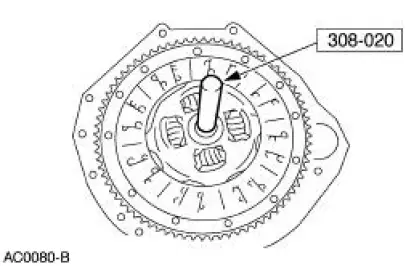

1. Position the clutch disc on the flywheel.

- Using the special tool, align the clutch disc.

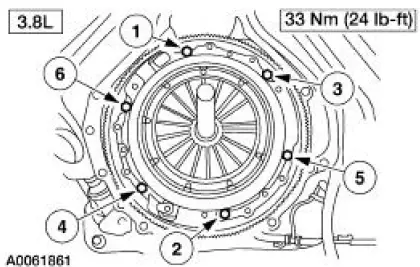

2. NOTE: If reusing the clutch pressure plate, align the plate using the marks made during removal.

Using the special tool, align the clutch pressure plate and install it on the dowels.

- Install the bolts in the sequence shown.

- Remove the special tool.

3. NOTE: Before installing the transmission, the ball stud, the clutch release lever and the input shaft must be cleaned and lubricated with grease.

Install the transmission.

Clutch (Description and Operation)

Clutch (Description and Operation)

The primary function of the clutch is to couple and uncouple engine power

to the transmission upon

driver command.

The clutch is a single plate, dry friction clutch disc. The clutch

disc ha ...

Disc and Pressure Plate - 4.6L (4V) Engine

Disc and Pressure Plate - 4.6L (4V) Engine

Special Tool(s)

Clutch Aligner

308-020 (T74P-7137-K)

Material

Item

Specification

Premium Long Life Grease

XG-1-C

ESA-M1C75-B

1. Disconnect the battery ground cable. ...

Other materials:

Selector Lever

Removal

1. Remove the shifter top control panel.

2. Disconnect the electrical connectors.

3. Remove the shifter bezel.

4. Remove the bulb from the bezel.

5. Disconnect the TCS connector.

6. CAUTION: Extra force may be needed to lift up on the handl ...

Checks and Services

Certain basic maintenance checks and inspections should be carried out at

specified intervals. Any

recognized adverse condition should be corrected as soon as possible.

Maximum Oil Change Interval (Normal Schedule)

8,000 km (5,000 miles) or 6 months, whiche ...

Spring Lock Coupling

The spring lock coupling is a refrigerant line coupling held together by a

garter spring inside a circular

cage.

When the coupling is connected together, the flared end of the female

fitting slips behind the

garter spring inside the cage of th ...