Ford Mustang (1999-2004) Service Manual: Cleaning

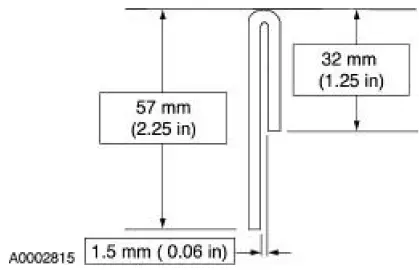

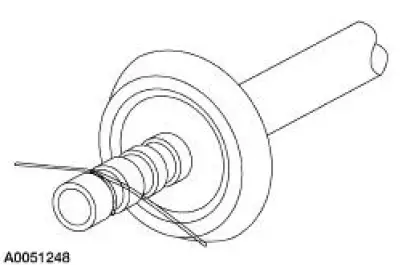

1. Fabricate a cleaning tool from a 1/8 inch diameter brazing rod.

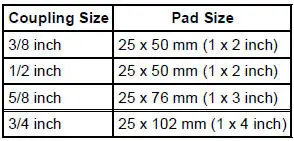

2. Cut an abrasive pad from maroon colored 3M Scotch Brite with the dimensions corresponding to the coupling size.

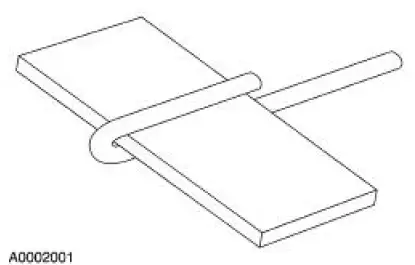

3. Assemble the pad to the tool.

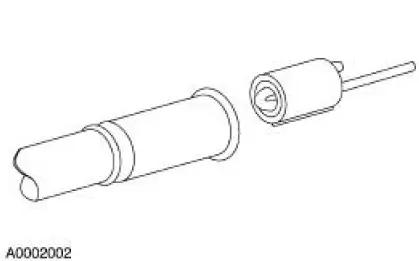

4. Coat the abrasive pad with PAG Refrigerant Compressor Oil (R-134a Systems) or equivalent.

5. Roll the pad on the tool and install it in a variable speed drill motor.

6. CAUTION: Maintain low speed drill rotation when inserting or removing the cleaning tool to prevent axial scratches which may cause future leaks.

Polish for one minute at moderate speed (less than 1,500 rpm) or until the surface is clean and free of scratches or foreign material.

7. Clean the fitting with a lint-free cloth.

8. Inspect the surface for grooves or scratches. If grooves and scratches are still present, install a new component.

9. Clean the O-ring seal grooves with a 300 mm (12 inch) length of natural fiber string.

- Loop the string around the grooves and pull the string back and forth.

10. Remove any foreign material from the grooves with a lint-free cloth.

Disconnect

Disconnect

1. Remove the A/C tube lock coupling clip (19E746), if equipped.

2. Fit the special tool to the spring lock coupling.

3. Push the tool into the cage opening to release the female fitting from the ...

Connect

Connect

1. Install the A/C tube lock coupling spring.

2. Lubricate the inside of the coupling with PAG Refrigerant Compressor Oil

(R-134a Systems) or

equivalent.

3. CAUTION: Use only the new O-ring seals ...

Other materials:

Mirror - Motor

Removal

1. Push in the upper edge of the mirror glass to the maximum travel.

2. Grasp the bottom of the mirror glass, pull outward and remove the mirror

glass.

3. Remove the mirror motor screws.

4. Disconnect the mirror motor electrical connector.

5. ...

Material

Item

Specification

Threadlock and

Sealer

E0AZ-19554-AA

WSK-M2G351-A5 (type

II)

Shoulder Bolt Kit

F5ZZ-76539A04-A

-

NOTE: Before starting the adjustment process, inspect the top for damage,

make sure that the door

window glass ...

Component Tests

Grid Wire Test

1. Using a bright lamp inside the vehicle, inspect the wire grid from

the exterior. A broken grid wire

will appear as a brown spot.

2. Run the engine at idle. Set the rear window defrost switch to ON. The

indicator light should

co ...