Ford Mustang (1999-2004) Service Manual: Component Tests

Ball Joint Inspection

1. Raise and support the vehicle.

2. Prior to performing any inspection of the ball joints, inspect the wheel bearings.

3. Position a safety stand beneath the front suspension lower arm (3079) to be tested.

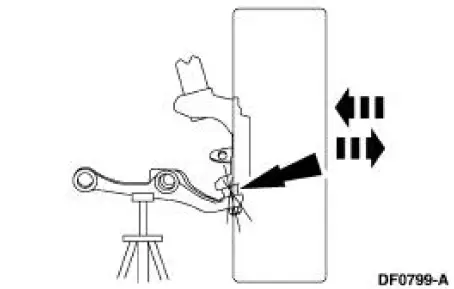

4. While an assistant pulls and pushes the bottom of the tire, observe the relative movement between the lower spindle arm and the front suspension lower arm ball joint. Any movement at or exceeding the specification indicates a worn or damaged lower ball joint. Install a new front suspension lower arm.

Wheel Bearing Inspection

1. Raise the vehicle until the tire is off the floor.

2. NOTE: Make sure the wheel rotates freely and the brake pads are retracted sufficiently to allow movement of the tire and wheel assembly.

Grasp each tire at the top and bottom and move the wheel inward and outward while lifting the weight of the tire off the wheel bearing.

3. If the tire and wheel (hub) is loose on the wheel spindle or does not rotate freely, install a new front wheel hub (1104) as necessary.

Symptom Chart

Symptom Chart

Condition

Possible Sources

Action

Dogtracking

Excessive rear

thrust angle.

Front or rear

suspension

components.

Drive axle

damaged.

...

Camber and Caster Adjustment - Front

Camber and Caster Adjustment - Front

All vehicles

1. Remove the rivet. Loosen the nuts and bolt.

Vehicles requiring camber adjustment

2. Move the front suspension camber adjusting plate (3B391) to the required

camber setting.

Vehicl ...

Other materials:

Retractor - Front Seat Safety Belt, Coupe

Special Tool(s)

Torx Bit, Safety Belt Bolt

501-010 (T77L-2100-A)

Removal

1. Remove the quarter trim panel (31012). For additional information, refer

to Section.

2. Using the special tool, remove the bolt and the safety belt retractor.

Remov ...

A/C Compressor Pressure Relief Valve

An A/C compressor pressure relief valve is incorporated into the compressor

A/C manifold and tube to:

relieve unusually high refrigerant system discharge pressure buildups.

For specifications

regarding operating pressure(s), refer to Section.

prevent ...

Trim Panel - Quarter, Convertible

Special Tool(s)

Safety Belt Bolt Bit

501-010 (T77L-2100-A)

Removal and Installation

1. Lower the convertible top to the full down position.

2. Remove the rear seat cushion.

3. Remove the two bolts and the rear seat backrest.

4. Remove ...