Ford Mustang (1999-2004) Service Manual: Flywheel

Removal

1. Remove the clutch components. 2. Remove the bolts and the flywheel.

Installation

1. To install, reverse the removal procedure.

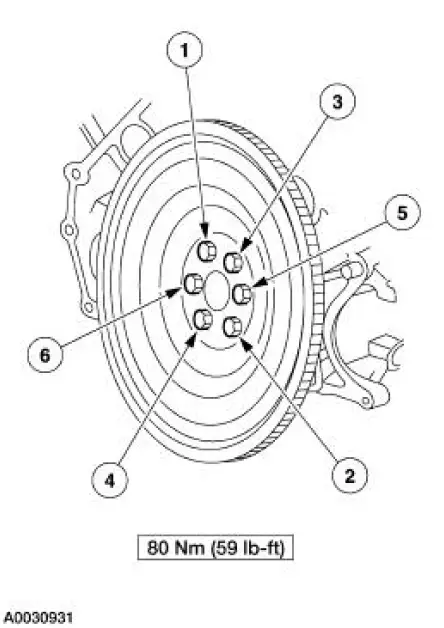

- Tighten the bolts in the sequence shown.

Installation

Installation

1. CAUTION: Do not use metal scrapers, wire brushes, power abrasive

discs or other

abrasive means to clean the sealing surfaces. These tools cause scratches and

gouges

which make leak paths. Use a p ...

Flexplate

Flexplate

Removal and Installation

1. Remove the transmission. For additional information, refer to Section.

2. Remove the six bolts retaining the flexplate to crankshaft, and remove the

flexplate.

3. To in ...

Other materials:

Wheel Studs

Special Tool(s)

C-Frame and Clamp Assembly

211-023 (T74P-3044-A1)

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A ...

Cleaning the engine

Engines are more efficient when they are clean because grease and dirt

buildup keep the engine warmer than normal.

When washing:

• Take care when using a power washer to clean the engine. The

high-pressure fluid could penetrate the sealed parts and cause

da ...

Intake Air Distribution and Filtering - Supercharger,

Charge Air Cooler

The supercharger (SC) is a positive displacement pump. Its purpose is to

supply an excess volume of

intake air to the engine by increasing air pressure and density in the

intake manifold. The supercharger

is matched to the engine by its displacement and ...