Ford Mustang (1999-2004) Service Manual: Wheel Hub or Axle Flange Face Runout

NOTE: If the axle shaft assembly is removed, check runout of the shaft itself. The forged (unmachined) part of the shaft is allowed to have as much as 3.0 mm (0.120 inch) runout. This alone will not cause a vibration condition.

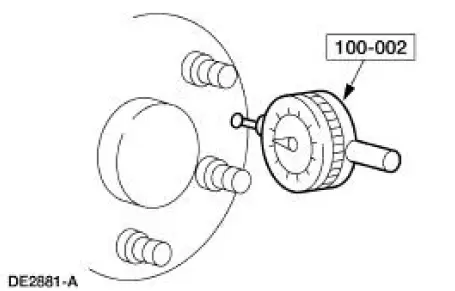

1. Position the special tool on the wheel hub or axle flange face, as close to the outer edge as possible. Zero the indicator to allow the pointer to deflect either way.

2. Rotate the hub or flange one full turn and note the maximum and minimum readings. The difference between the maximum and minimum readings will be the total face runout. The runout must not exceed 0.127 mm (0.005 inch).

Drive Pinion Stem and Pinion Flange

Check the pinion flange runout when all other checks have failed to show the cause of vibration.

One cause of excessive pinion flange runout is incorrect installation of the axle drive pinion seal.

Check to see if the spring on the seal lip has been dislodged before installing the ring gear and pinion.

Axle Noise

NOTE: Before disassembling the axle to diagnose and correct gear noise, eliminate the tires, exhaust, trim items, roof racks, axle shafts and wheel bearings as possible causes. The noises described as follows usually have specific causes that can be diagnosed by observation as the unit is disassembled. The initial clues are the type of noise heard during the road test.

Wheel Hub or Axle Flange Bolt Circle Runout

Wheel Hub or Axle Flange Bolt Circle Runout

NOTE: The brake discs must be removed to carry out all runout

measurements.

1. Position the special tool perpendicular to the wheel hub or axle flange bolt,

as close to the hub

or flange face as po ...

Gear Howl and Whine

Gear Howl and Whine

Howling or whining of the ring gear and pinion is due to an incorrect gear

pattern, gear damage or

incorrect bearing preload. ...

Other materials:

Exhaust Manifold RH

Removal and Installation

1. Disconnect the battery negative cable. For additional information,

refer to Section.

2. Remove the air cleaner outlet pipe. For additional information, refer to

Section.

3. Disconnect the differential pressure feedback exha ...

Radiator

Material

Item

Specification

Motorcraft Premium Gold

Engine Coolant

VC-7-A (in Oregon VC-7-B)

(yellow color)

WSS-M97B51-

A1

Removal and Installation

NOTE: Radiator removal and installation is similar for both 3.8L and

4.6L vehicles. ...

Installation

1. Install the bearing.

1. Position the knuckle on the press.

2. Using the appropriate step plate adapter, press the bearing into the

knuckle until the

bearing clears the snap ring groove and bottoms out in the bore.

2. Install the snap ring.

3. CA ...