Ford Mustang (2005-2014) Owners Manual: Adjusting the headlamps

The headlamps on your vehicle are properly aimed at the assembly plant.

If your vehicle has been in an accident, an authorized dealer should check the alignment of your headlamps.

Vertical Aim Adjustment

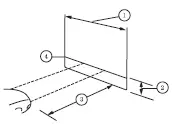

1. Park the vehicle directly in front of a wall or screen on a level surface, approximately 25 ft (7.6 m) away.

• (1) 8 ft (2.4 m)

• (2) Center height of lamp to

ground

• (3) 25 ft (7.6 m)

• (4) Horizontal reference line

2. Measure the height from the center of your headlamp to the ground

and mark an 8 ft (2.4 m) horizontal reference line on the vertical wall or

screen at this height (a piece of masking tape works well). The center of

the lamp is marked by a 3 millimeter circle on the headlamp lens.

3. Turn on the low beam headlamps to illuminate the wall or screen and

open the hood. To see a clearer light pattern for adjusting, block the

light from one headlamp while adjusting the other.

On the wall or screen, you will observe a flat zone of high intensity light located at the top of the right hand portion of the beam pattern.

If the top edge of the high intensity light zone is not at the horizontal reference line, the headlamp will need to be adjusted.

4. Locate the vertical adjuster on

each headlamp.

5. Then use a 7 mm Allen wrench or a Phillips screwdriver to adjust the

vertical aim of the headlamp. HORIZONTAL AIM IS NOT REQUIRED

FOR THIS VEHICLE AND IS NON-ADJUSTABLE.

6. Close the hood and turn off the lamps.

Air filter check

Air filter check

WARNING: To reduce the risk of vehicle damage and or

personal burn injuries, do not start your engine with the air

cleaner removed and do not remove it while the engine is running.

Note: Failure to us ...

Changing a bulb

Changing a bulb

Lamp Assembly Condensation

Exterior lamps are vented to accommodate normal changes in pressure.

Condensation can be a natural by-product of this design. When moist air

enters the lamp assembly throug ...

Other materials:

Entertainment

Your system offers many media options. You can access these options

using the touchscreen or voice commands.

AM/FM Radio

Press the RADIO hard button.

To change between AM, FM1 and FM2, touch the AM or FM

tab. You can also access satellite radio by pressing t ...

Removal

1. Remove the center instrument panel register.

2. Remove the screws.

3. Disconnect the connectors.

4. Using the special tool, disconnect the temperature control cable from the

control head.

5. Remove the nuts and disconnect the vacuum connector.

...

Fuel System (Description and Operation)

Component Location

WARNING: Do not smoke or carry lighted tobacco or open flame of any

type when

working on or near any fuel-related components. Highly flammable mixtures are

always present

and may be ignited, resulting in possible personal injury ...