Ford Mustang (1999-2004) Service Manual: Assembly

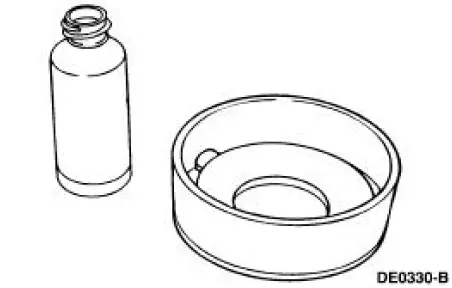

1. CAUTION: 118 ml (4 oz) of the specified Ford Friction Modifier must be used in the axle.

Lubricate each steel clutch plate and soak all friction plates for no less than 15 minutes.

- Use Additive Friction Modifier C8AZ-19B546-A or equivalent meeting Ford specification EST-M2C118-A

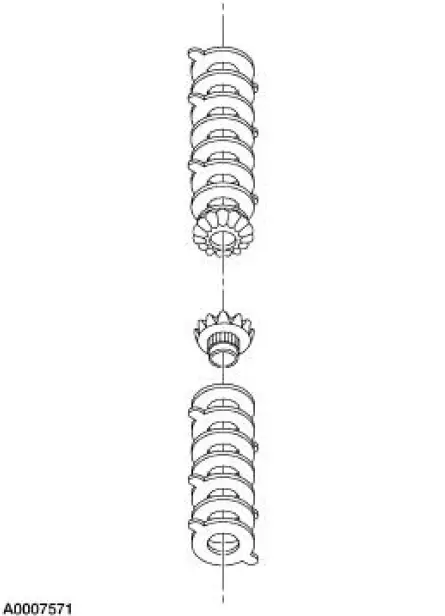

2. CAUTION: Do not mix the differential clutch packs or shims from one side with the other.

Assemble the differential clutch packs (without the shims) on their respective differential side gears.

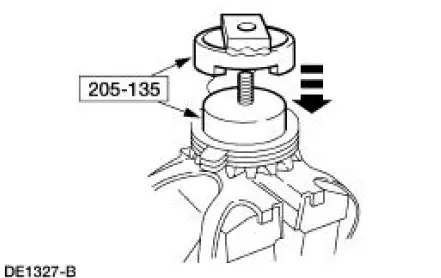

3. Place the base portion of the special tool in a vise. Install the differential differential side gear and differential clutch pack (without the shim) on the tool.

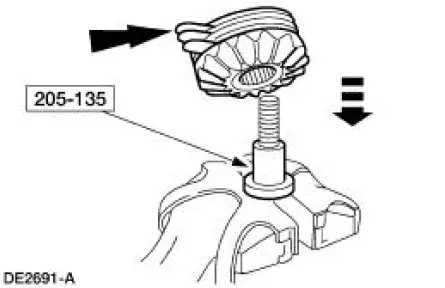

4. Position the special tool hand-tight on top of the differential clutch pack.

5. Install the special tool over the disc and differential clutch pack.

6. Install the nut.

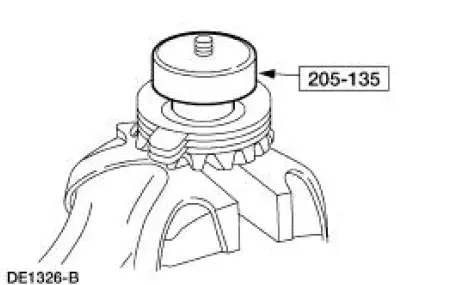

7. NOTE: Clutch Pack Rebuild Kit F5AZ-4947-A is available for this application.

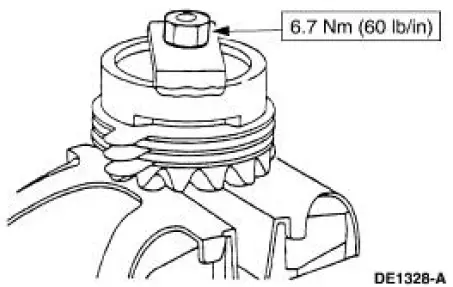

Select and insert the thickest feeler gauge blade that will enter between the tool and the differential clutch pack. The reading will be the thickness of the new clutch shim.

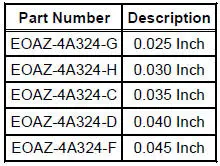

Selective Shims

8. Remove the special tools from the differential clutch pack and differential side gear assembly.

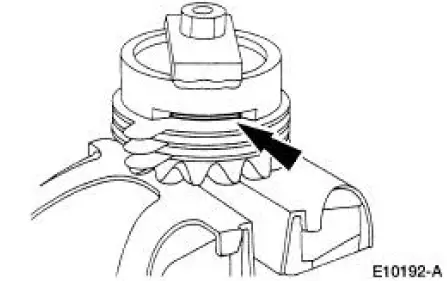

9. Install shim(s) on the differential clutch pack and differential side gear assembly.

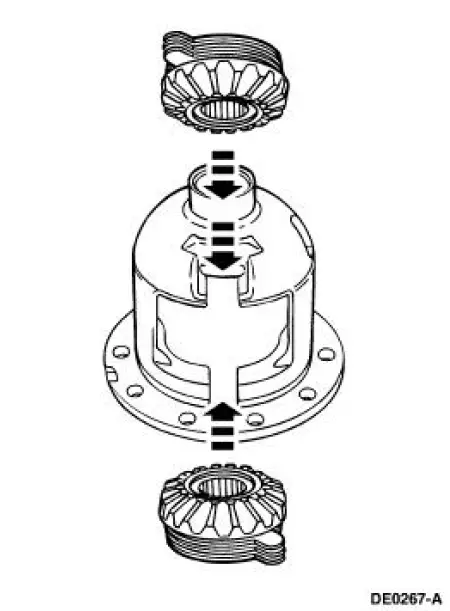

10. Install the differential side gear assemblies in the differential case.

11. Install the differential pinion gear and differential pinion thrust washer assemblies in the differential case.

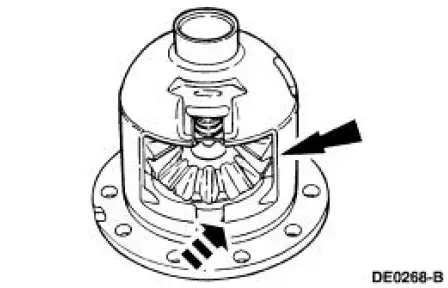

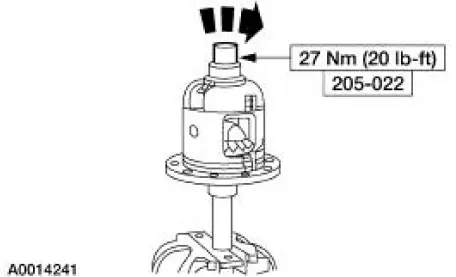

12. Using a soft-faced hammer, install the differential clutch spring.

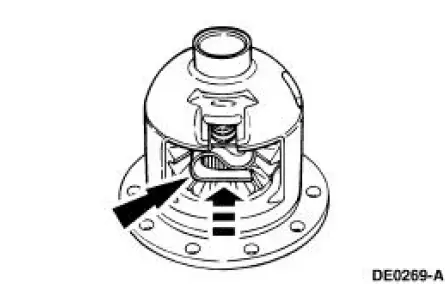

13. Install the differential pinion shaft and install a new bolt finger-tight.

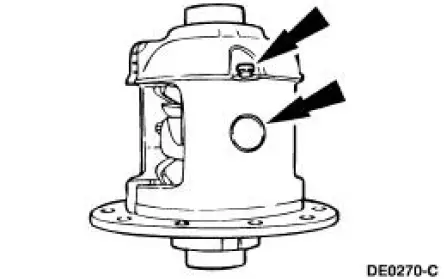

14. Mount the differential case and the special tool in a vise. Using the special tool, check the torque necessary to rotate one differential side gear.

- If reusing the original clutch plates, the initial minimum break-away torque must be no less than the specification. The minimum rotating torque necessary to keep the differential side gear turning with new clutch plates may vary.

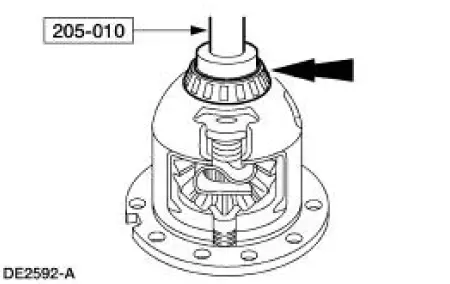

15. Using the special tool, install the differential bearings, if removed.

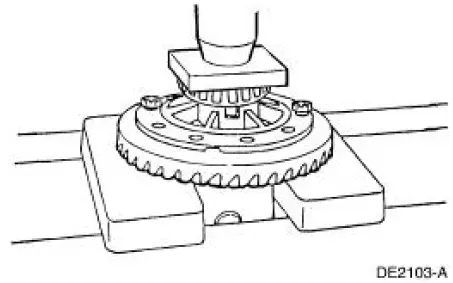

16. Position the differential ring gear and the differential case. Align the bolt holes by starting two bolts through the holes in the differential case and the differential ring gear. Press the differential ring gear on the differential case.

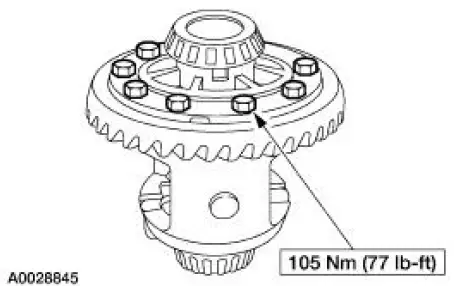

17. Install the bolts.

- Apply Stud and Bearing Mount EOAZ-19554-BA or equivalent meeting Ford specification WSK-M2G349-A1 to the bolt threads.

18. Install the differential assembly in the differential housing. For additional information, refer to Differential Case in this section.

Disassembly

Disassembly

1. Remove the differential assembly from the differential housing. For

additional information, refer

to Differential Case in this section.

2. Remove the 10 bolts.

3. CAUTION: Do not damage the thr ...

Rear Drive Axle/Differential - Ford 8.8-Inch IRS

Rear Drive Axle/Differential - Ford 8.8-Inch IRS

General Specifications

Torque Specifications

a: Use Stud and Bearing Mount EOAZ-19554-BA or equivalent meeting Ford

specification WSKM2G349-

A1.

b: With pinion flange yoke seal. ...

Other materials:

Principles of Operation

Battery Saver

The battery saver feature provides automatic shut-off of power to demand

and courtesy lamp circuitry.

When the generic electronic module (GEM) detects the ignition switch

circuits are in the key OFF or

removed ignition key positions, powe ...

Installation

1. Lubricate the lip of the wheel bearing oil seal

Use Premium Long-Life Grease XG-1-C or equivalent meeting Ford

specification ESAM1C75-

B.

2. CAUTION: Do not damage the wheel bearing oil seal.

Install the two axle shafts.

3. CAUTION: Do not damage th ...

SecuriLock® passive anti-theft system

Note: The system is not compatible with non-Ford aftermarket remote

start systems. Use of these systems may result in vehicle starting

problems and a loss of security protection.

Note: Metallic objects, electronic devices or a second coded key on the

same key ...