Ford Mustang (1999-2004) Service Manual: Bearings - Inspection

NOTE: If any of the following conditions exist, install a new bearing.

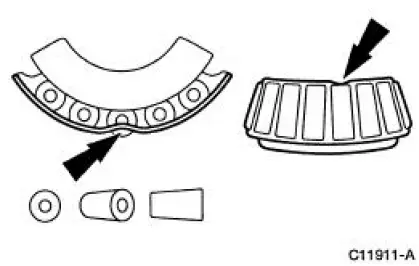

1. Inspect the bearing for a bent cage.

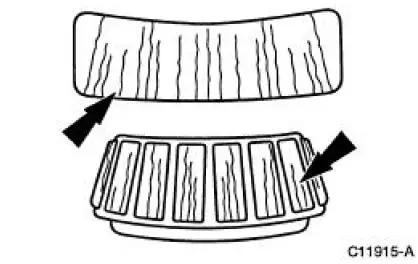

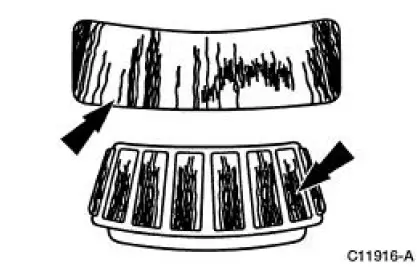

2. Inspect bearings for galling (metal smears on roller ends).

- Galling is caused by overheating, poor lubrication or an overload situation.

- If galling is found, install a new bearing and inspect the seals.

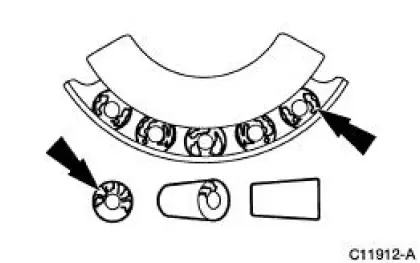

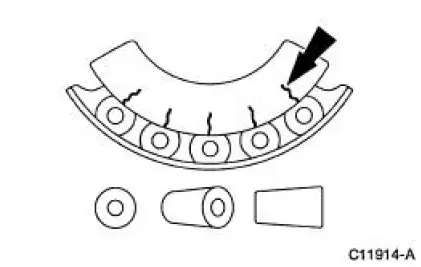

3. Inspect the bearing for brinelling (surface indentations in the raceway).

4. Inspect bearing for cracked inner race.

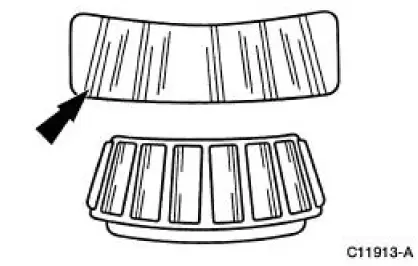

5. Inspect the bearing and raceway for etching.

- If etching is present, inspect the seals.

6. Inspect the bearing for heat discoloration (dark blue).

- If heat discoloration is evident, check the bearing and race for loss of temper. Draw a file across the component. If the file cuts the metal, there is a loss of temper.

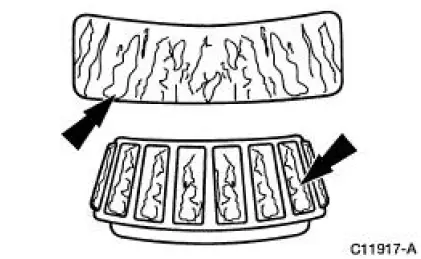

7. Inspect the bearing for fatigue spalling (metal flaking).

Manual Transmission

Manual Transmission

The TR3650 five-speed manual transmission features the following:

The fifth speed gear functions as an overdrive gear.

The forward gears are synchronized and helical cut.

The reverse gear oper ...

Seal

Seal

Special Tool(s)

Installer, Transmission

Extension Housing Oil Seal

308-227 (T94P-7657-A)

Slide Hammer

100-001 (T50T-100-A)

Remover, Bushing

307-001 (TOOL-117 ...

Other materials:

Window Regulator - Power

Removal

1. Remove the door window glass. For additional information, refer to

Window Glass-Door in this

section.

2. Disconnect the electrical connector.

3. Remove the channel.

4. Remove the regulator.

Installation

1. To install, reverse the r ...

Stay Pad - Convertible Top

Removal

1. Remove the convertible top material. For additional information, refer to

Convertible Top

Material in this section.

2. Remove the rear window glass. For additional information, refer to

Convertible Top Assembly-

Rear Window Glass in this section. ...

Engine (Removal)

Special Tool(s)

Lifting Bracket Set, Engine

303-D095 (D94L-6001-A) or

equivalent

Spreader Bar

303-D089 (D93P-6001-A3) or

equivalent

Heavy Duty Floor Crane

014-00071 or equivalent

Removal

WARNING: Do not smoke or ...