Ford Mustang (1999-2004) Service Manual: Chuckle

Chuckle that occurs on the coast driving phase is usually caused by excessive clearance between the differential gear hub and the differential case bore.

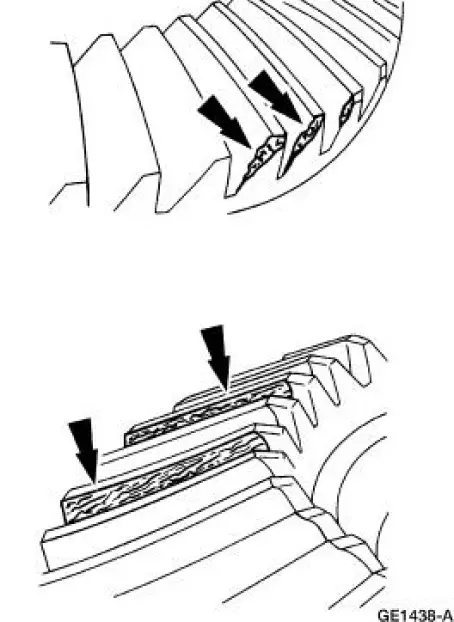

Damage to a gear tooth on the coast side can cause a noise identical to a chuckle. A very small tooth nick or ridge on the edge of a tooth can cause the noise.

Clean the gear tooth nick or ridge with a small grinding wheel. If the damaged area is larger than 3.2 mm (1/8 inch), install a new gearset.

To check the ring gear and pinion, remove as much lubricant as possible from the gears with clean solvent. Wipe the gears dry or blow them dry with compressed air. Look for scored or damaged teeth.

Also look for cracks or other damage.

If either gear is scored or damaged badly, install a new ring gear and pinion.

If metal has broken loose, the axle housing must be cleaned to remove particles that will cause damage. At this time, any other new parts in the axle housing must also be installed, if necessary.

Bearing Whine

Bearing Whine

Bearing whine is a high-pitched sound similar to a whistle. It is usually

caused by worn/damaged

pinion bearings, which are operating at driveshaft speed. Bearing noise occurs

at all driving speeds. ...

Knock

Knock

Knock, which can occur on all driving phases, has several causes including

damaged teeth or gearset.

In most cases, one of the following conditions will occur:

1. A gear tooth damaged on the drive s ...

Other materials:

Evaporative Emission Canister

Removal and Installation

1. WARNING: The evaporative emission system contains fuel vapor

and condensed

fuel vapor. Although not in large quantities, it still presents the

danger of explosion or

fire. Disconnect the battery ground cable from the bat ...

Crankshaft - Connecting Rod Journal Taper, Out of Round

1. Measure the crankshaft connecting rod journal diameters in two

directions perpendicular to one

another at each end of the connecting rod journal. The difference in the

measurements from

one end to the other is the taper. Verify measurement is within t ...

Headliner

Removal

1. Remove the two upper quarter panels. For additional information,

refer to Trim Panel-Upper

Quarter in this section.

2. Remove the two windshield side garnish mouldings.

3. Remove the two sun visors.

1. Remove the six screws.

2. ...