Ford Mustang (1999-2004) Service Manual: Bearing Whine

Bearing whine is a high-pitched sound similar to a whistle. It is usually caused by worn/damaged pinion bearings, which are operating at driveshaft speed. Bearing noise occurs at all driving speeds.

This distinguishes it from gear whine which usually comes and goes as speed changes.

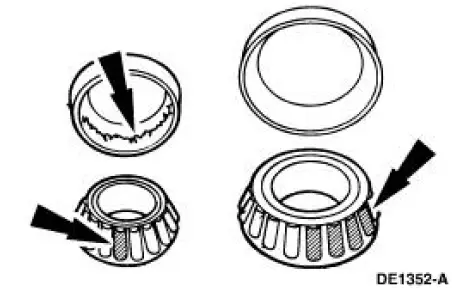

As noted, pinion bearings make a high-pitched, whistling noise, usually at all speeds. If however there is only one pinion bearing that is worn/damaged, the noise may vary in different driving phases. If pinion bearings are scored or damaged or there is a specific pinion bearing noise, new pinion bearings must be installed. A worn/damaged bearing will normally be obvious at disassembly. Examine the large end of the rollers for wear. If the pinion bearings original blend radius has worn to a sharp edge, a new pinion bearing must be installed.

NOTE: A low-pitched rumble normally associated with a worn/damaged wheel bearing can also be caused by tires.

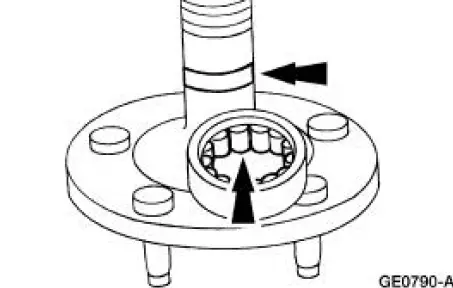

A wheel bearing noise can be mistaken for a pinion bearing noise. Check the wheel bearing for a spalled cup, and spalled/damaged rollers. Check the wheel bearing for rotating smoothness and end play. Install a new wheel bearing if any of these concerns are detected.

If the wheel bearing is damaged, the roller surface on the axle shaft may also be damaged. Install a new axle shaft if any damage is detected.

Gear Howl and Whine

Gear Howl and Whine

Howling or whining of the ring gear and pinion is due to an incorrect gear

pattern, gear damage or

incorrect bearing preload. ...

Chuckle

Chuckle

Chuckle that occurs on the coast driving phase is usually caused by excessive

clearance between the

differential gear hub and the differential case bore.

Damage to a gear tooth on the coast side can ...

Other materials:

Safety Belt System (Description and Operation)

WARNING: All safety belt assemblies include retractors, buckles, front

seat belt buckle

support assemblies (slide bar, if so equipped), shoulder belt height adjuster

(if equipped), child

safety seat tether bracket assemblies (if equipped) and attaching hardw ...

Installation

1. CAUTION: To prevent refrigerant system contamination, do not allow

dirt or other

foreign materials to enter the A/C compressor.

Clean the A/C compressor nose area.

2. Place the shaft seal on the special tool. Lubricate the shaft seal and the

special tool ...

Checks and Services

Certain basic maintenance checks and inspections should be carried out at

specified intervals. Any

recognized adverse condition should be corrected as soon as possible.

Maximum Oil Change Interval (Normal Schedule)

8,000 km (5,000 miles) or 6 months, whiche ...