Ford Mustang (1999-2004) Service Manual: Crankshaft Runout

Special Tool(s)

|

|

Dial Indicator Gauge with Holding Fixture 100-002 (TOOL-4201-C) or equivalent |

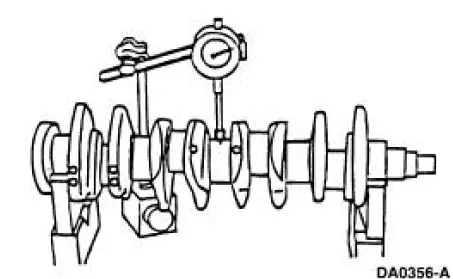

1. NOTE: Crankshaft main bearing journals must be within specifications before checking runout.

Use the Dial Indicator Gauge with Holding Fixture to measure the crankshaft runout.

- Refer to the appropriate section in Group 303 for the procedure.

- Rotate the crankshaft and subtract the lowest dial indicator reading from the highest dial indicator reading to figure the crankshaft runout. If it is out of specification, install new components as necessary. Refer to the appropriate section in Group 303 for the procedure.

Crankshaft End Play

Crankshaft End Play

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

1. Measure the crankshaft end play. Use a Dial Indicator Gauge with Holding

Fixture t ...

Crankshaft - Connecting Rod Journal Taper, Out of Round

Crankshaft - Connecting Rod Journal Taper, Out of Round

1. Measure the crankshaft connecting rod journal diameters in two

directions perpendicular to one

another at each end of the connecting rod journal. The difference in the

measurements from

one e ...

Other materials:

Drive Pinion

Special Tool(s)

Adapter for 205-S127

205-105 (T76P-4020-A3)

Adapter for 205-S127

205-109 (T76P-4020-A9)

Adapter for 205-S127

205-110 (T76P-4020-A10)

Adapter for 205-S127

205-111 (T76P-4020-A11)

Adapter for 20 ...

Forward Clutch Cylinder

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

Compressor, Clutch Spring

307-096 (T81P-70235-A)

Protector, Transmission

Forward Clutch Outer Fluid

Seal

307-423

M ...

Disassembly

1. WARNING: To avoid risk of serious personal injury, follow all

warnings, cautions,

notes and instructions in the driver air bag removal and installation procedure.

Remove the steering column (3C529). For additional information, refer to Column

in this

s ...