Ford Mustang (1999-2004) Service Manual: Disassembly

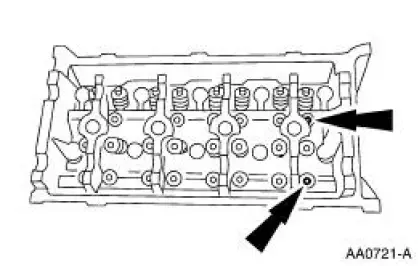

1. CAUTION: Do not place the cylinder head flat on the bench; the valves will bend.

CAUTION: Before disassembly begins, mark the valve position on the face of each valve being removed. The valves must be re-installed into the same positions.

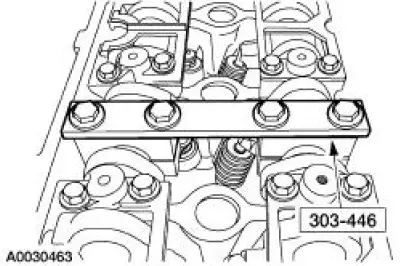

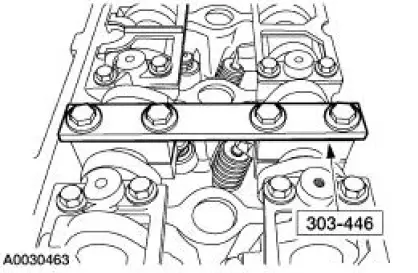

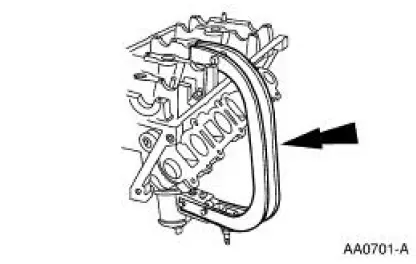

Install the special tool.

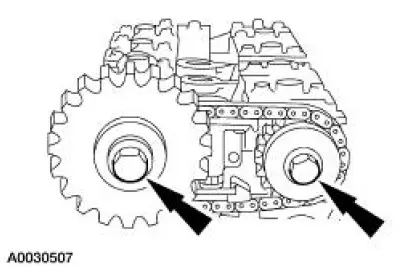

2. Remove the exhaust camshaft sprocket and the intake camshaft bolt, washer and spacer.

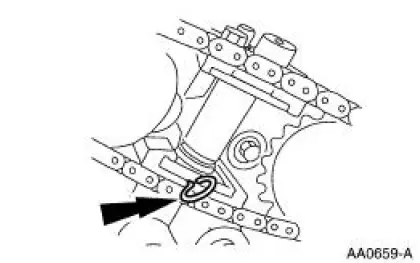

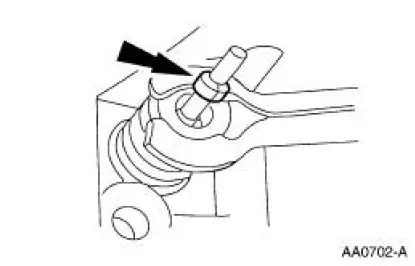

3. Compress the tensioner and install a lock pin.

4. Remove the special tool.

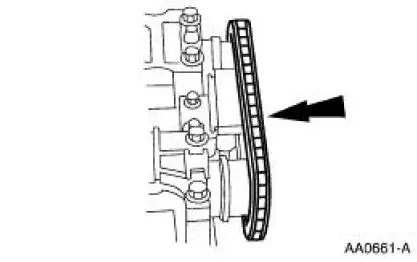

5. Remove the timing chain and the camshaft sprocket.

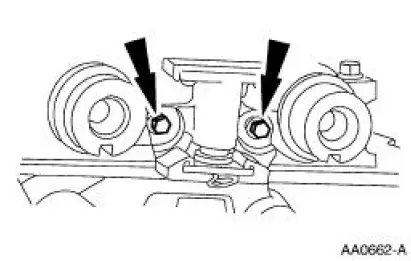

6. NOTE: LH tensioner is shown, RH tensioner is similar.

Remove the tensioner.

7. Remove the roller followers on the base circle.

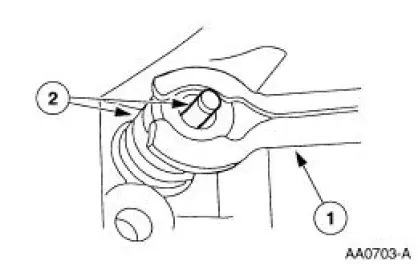

1. Install the special tool on the valve spring.

2. Compress the tool and remove the roller follower.

8. Repeat the previous step for the remaining roller followers.

9. Remove the hydraulic lash adjusters.

10. CAUTION: Make sure the tool is seated correctly on the valve spring. Apply a small amount of air at a time. This will prevent the tool from shifting and causing damage to the cylinder head.

Install the air-operated spring compressor on the cylinder head.

11. Compress the valve spring compressor and remove the key from the valves.

12. Remove the intake valves and the valve springs.

1. Release the pressure and remove the valve spring compressor.

2. Remove the intake valves and the valve springs from the cylinder head.

13. Remove the valve stem seals.

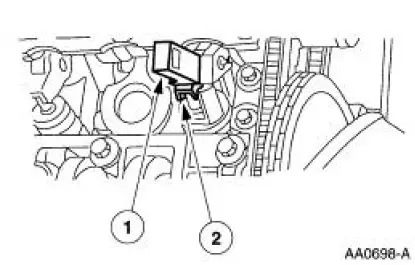

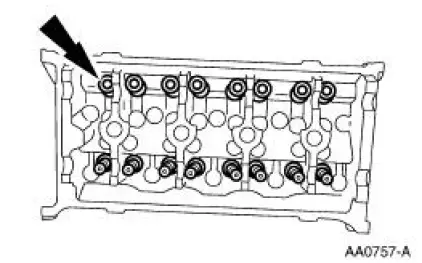

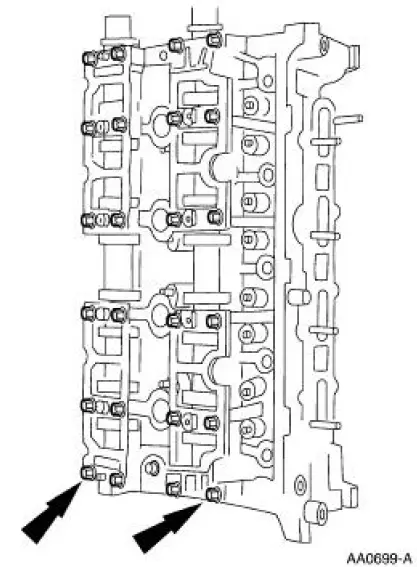

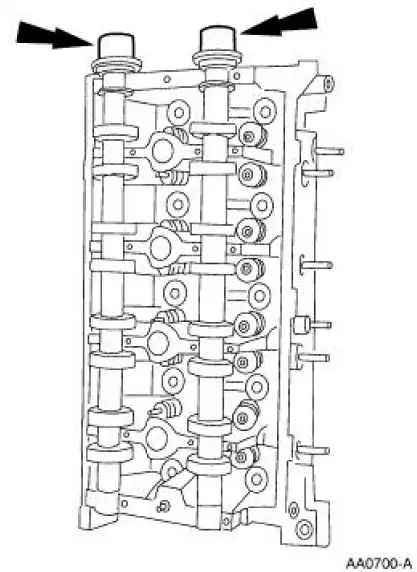

14. CAUTION: The outer bolts on the outer cam bearing cap (exhaust) are longer and must be returned to the same location or engine damage may occur.

NOTE: Identify the camshaft-to-cylinder head location. Caps are not interchangeable.

Remove the bolts and the camshaft bearing cap assemblies.

15. Remove the camshafts.

Cylinder Head

Cylinder Head

Special Tool(s)

Compressor, Valve Spring

(Exhaust Side)

303-567 (T97P-6565-AH)

Compressor, Valve Spring

(Intake Side)

303-452 (T93P-6565-AR)

Holding Tool, ...

Assembly

Assembly

1. Install the valve stem seals.

2. Install the valves and the valve springs.

3. CAUTION: Make sure the tool is seated correctly on the valve spring.

Apply a small

amount of air at a time. This wil ...

Other materials:

Installation

1. Install the lower intake manifold gaskets.

2. Connect the fuel charging wiring harness to the rear of the lower intake

manifold and install the

manifold.

3. Install the intake manifold fasteners and tighten in the sequence shown.

4. Position the fuel ...

Reservoir

Removal

WARNING: Brake fluid contains polyglycol ethers and polyglycols.

Avoid contact with

eyes. Wash hands thoroughly after handling. If brake fluid contacts eyes,

flush eyes with

running water for 15 minutes. Get medical attention if irritation persi ...

Switch - Deactivator

Removal

1. Disconnect the battery ground cable.

2. Remove the deactivator switch.

1. Disconnect the deactivator switch electrical connector.

2. Detach the lower deactivator switch hook.

3. Detach the upper deactivator pivot.

Installation

1. N ...