Ford Mustang (1999-2004) Service Manual: Disc and Pressure Plate - 4.6L (4V) Engine

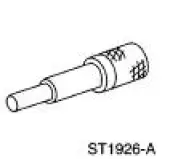

Special Tool(s)

|

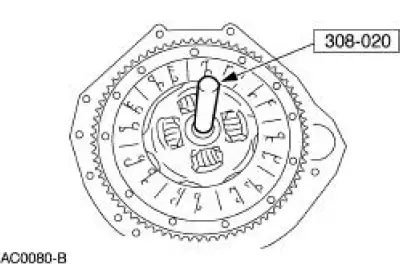

Clutch Aligner 308-020 (T74P-7137-K) |

Material

| Item | Specification |

| Premium Long Life Grease XG-1-C | ESA-M1C75-B |

1. Disconnect the battery ground cable. For additional information, refer to Section.

2. Remove the transmission. For additional information, refer to Section.

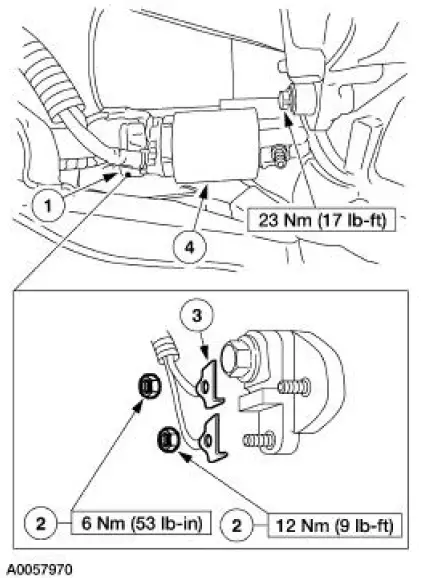

3. Remove the starter.

1. Remove the terminal cap.

2. Remove the nuts.

3. Remove the wires and position them aside.

4. Remove the two bolts and the starter.

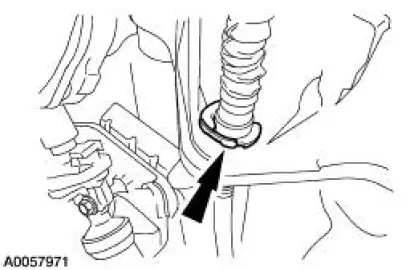

4. Remove the clutch cable clip, then pull the cable through the clutch housing.

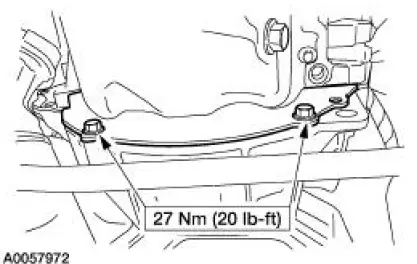

5. Remove the two bolts and the inspection cover.

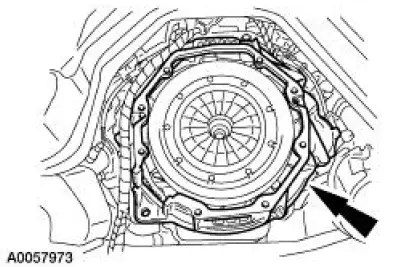

6. Remove the seven bolts and the clutch housing.

7. CAUTION: Loosen the bolts evenly to prevent damage to the pressure plate.

NOTE: If the pressure plate is to be reused, index-mark the pressure plate to the flywheel.

Remove the six bolts and the pressure plate and disc.

Installation

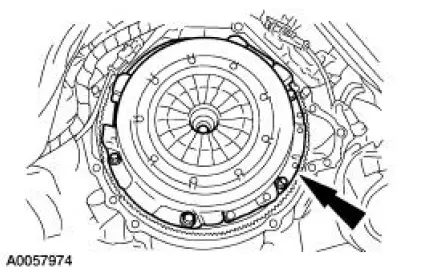

1. NOTE: Clean the clutch pressure plate and flywheel with a commercial alcohol-based solvent so surfaces are free from oil film. Do not use cleaners with a petroleum base.

NOTE: Before installing the transmission, the ball stud, the clutch release lever and the input shaft must be cleaned and lubricated with grease.

To install, reverse the removal procedure.

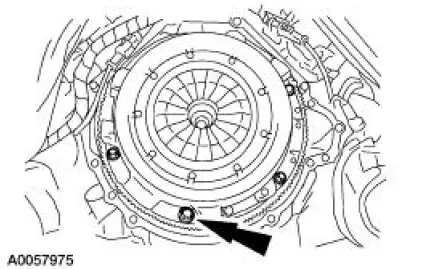

- Using the special tool, align the clutch disc and pressure plate to the flywheel.

2. Tighten the pressure plate bolts in two stages.

- Stage 1: Tighten the bolts to 45 Nm (33 lb-ft).

- Stage 2: Tighten the bolts an additional 60 degrees.

Disc and Pressure Plate - 3.8L and 4.6L (2V) Engines

Disc and Pressure Plate - 3.8L and 4.6L (2V) Engines

Special Tool(s)

Clutch Aligner

308-020 (T74P-7137-K)

Material

Item

Specification

Premium Long Life Grease

XG-1-C

ESA-M1C75-B

1. Remove the transmission.

2. CAUTION ...

Pilot Bearing

Pilot Bearing

Special Tool(s)

Puller with Slide Hammer

308-001 (T58L-101-B)

1. Remove the clutch disc and the clutch pressure plate. For additional

information, refer to Disc

and Pressure Plate-3.8 ...

Other materials:

Ignition Coil

Material

Item

Specification

Silicone Brake Caliper Grease

and Dielectric Compound

D7AZ-19A331-A or equivalent

ESE-M1C171-

A

Removal and Installation

1. Disconnect the battery ground cable (14301). For additional

information, refer to ...

Master Cylinder - Hydro-Boost

Removal

1. Disconnect the fluid level sensor connector.

2. Disconnect the brake tubes.

3. Remove the brake master cylinder nuts.

4. Remove the brake master cylinder (2140).

Installation

1. To install, reverse the removal procedure.

Bleed the brak ...

Front Bumper

Special Tool(s)

Heavy-Duty Riveter

501-D011 (D80L-23200-A)

Removal and Installation

All vehicles except Cobra

1. Remove the front bumper cover. For additional information, refer to Front

Bumper Cover in this

section.

Cobra

2. Remove the charge ...