Ford Mustang (1999-2004) Service Manual: Front Subframe - 3.8L Engine

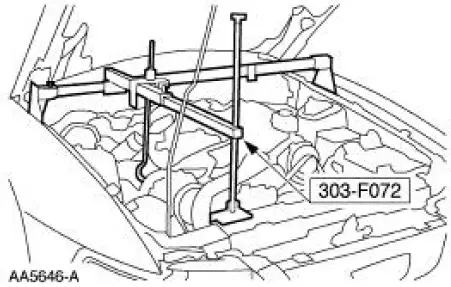

Special Tool(s)

|

3-Bar Engine Support Kit 303-F072 |

|

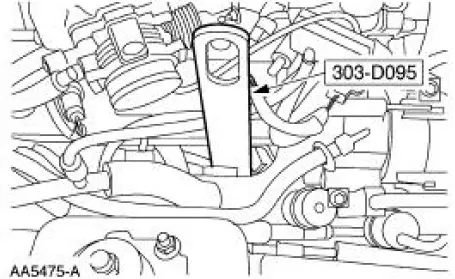

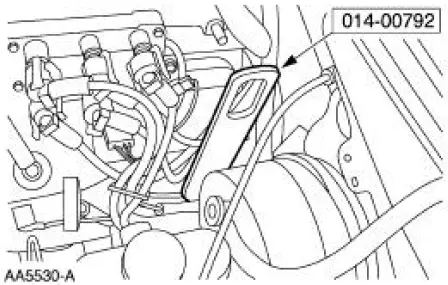

Lifting Bracket Set, Engine 303-D095 (D94L-6001-A) (014- 00792) |

Removal and Installation

All vehicles

1. Remove the steering gear. For additional information, refer to Section.

2. Remove the lower control arms. For additional information, refer to Section.

Vehicles with convertible top

3. Remove the front subframe support. For additional information, refer to Subframe Support- Convertible in this section.

Vehicles with hard top

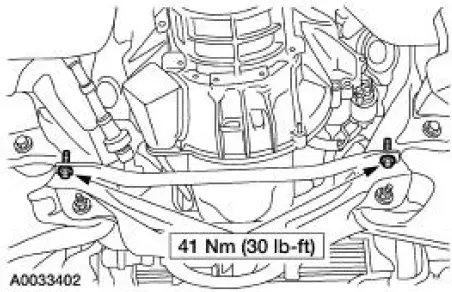

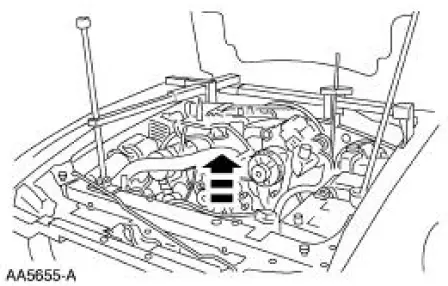

4. Remove the front subframe brace.

- Remove the bolts.

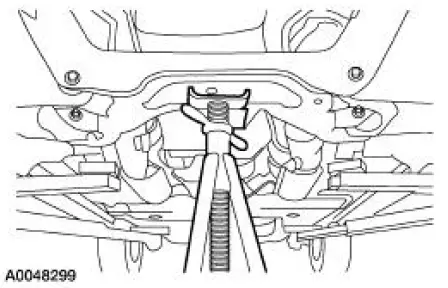

All vehicles

5. Lower the vehicle.

6. Install the special tool.

7. Install the special tool.

8. Install the special tool.

9. Raise and support the vehicle.

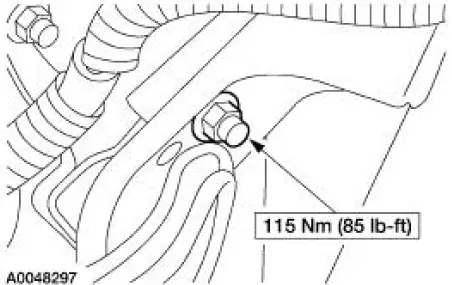

10. Remove the LH engine mount nut.

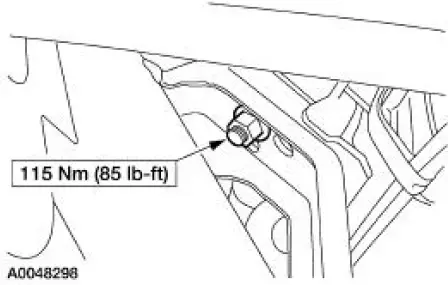

11. Remove the RH engine mount nut.

12. Lower the vehicle.

13. Using the special tool, raise and support the engine.

14. Raise the vehicle.

15. Support the front subframe.

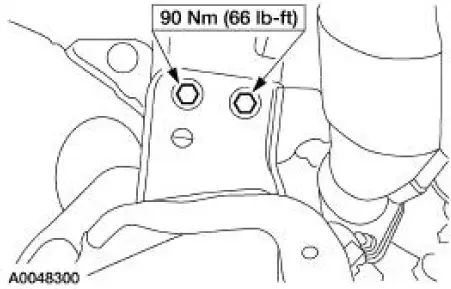

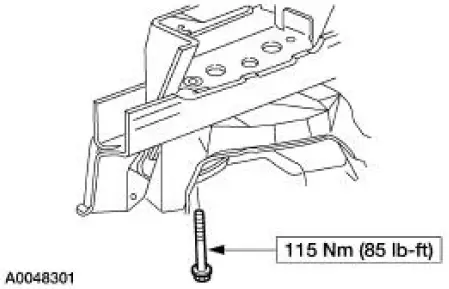

16. Remove the four front subframe lower bolts.

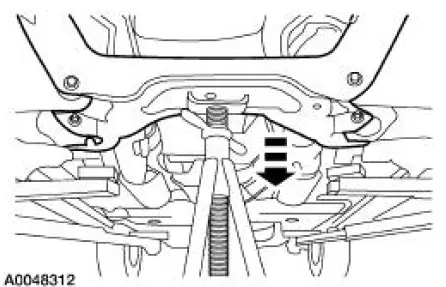

17. Remove the four front subframe upper bolts.

18. NOTE: Two technicians are needed to carry out this step.

Lower and remove the front subframe.

19. To install, reverse the removal procedure.

Underbody Misalignment Check

Underbody Misalignment Check

Underbody Dimensions

1. Underbody dimensions tolerances are +- 3.175 mm (0.125 in). Reference

dimensions are not

controlled dimensions. Reference points are +- 4.76 mm (0.1875 in). All und ...

Front Subframe - 4.6L (2V) Engine

Front Subframe - 4.6L (2V) Engine

Special Tool(s)

Support Bar, Engine

303-290-A

Lifting Bracket, Engine

303-D088 (D93P-6001-A2)

Removal and Installation

All vehicles

1. Remove the steering gear. For addit ...

Other materials:

Fuel Filter

Removal

WARNING: Fuel supply lines on all vehicles equipped with fuel injected

engines will

remain pressurized for long periods of time after engine shutdown. Fuel system

pressure must

be relieved prior to fuel system service to prevent possible personal inj ...

Installation

1. Install the RH engine insulator.

Install the nuts.

Install the bolts.

2. Install the LH engine insulator.

3. Connect the engine ground strap.

4. Install the bracket.

5. Lower the vehicle.

6. Lower the engine.

7. Raise the vehicle.

8. Ins ...

Economical driving

Fuel economy is affected by several things, such as how you drive, the

conditions you drive under and how you maintain your vehicle.

There are some things to keep in mind that may improve your fuel

economy:

• Accelerate and slow down in a smooth, moderate f ...