Ford Mustang (1999-2004) Service Manual: Front Subframe - 4.6L (2V) Engine

Special Tool(s)

|

Support Bar, Engine 303-290-A |

|

Lifting Bracket, Engine 303-D088 (D93P-6001-A2) |

Removal and Installation

All vehicles

1. Remove the steering gear. For additional information, refer to Section.

2. Remove the lower control arms. For additional information, refer to Section.

Vehicles with convertible top

3. Remove the front subframe support. For additional information, refer to Subframe Support - Convertible in this section

Vehicles with hard top

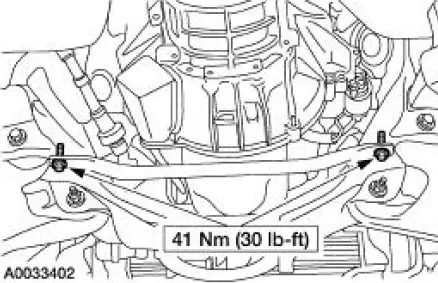

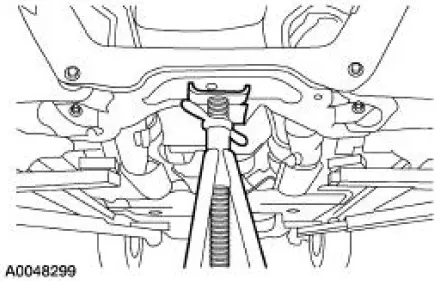

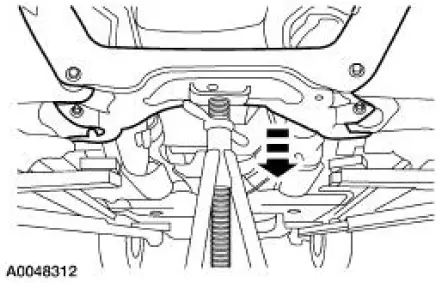

4. Remove the front subframe brace.

- Remove the bolts

All vehicles

5. Lower the vehicle.

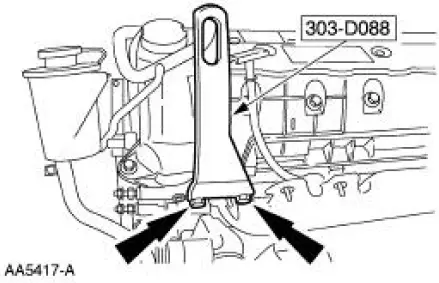

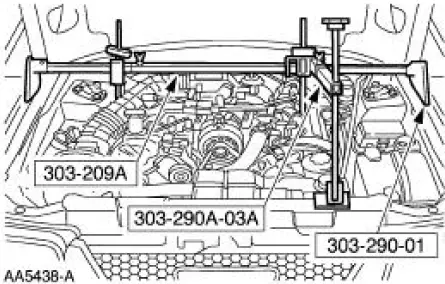

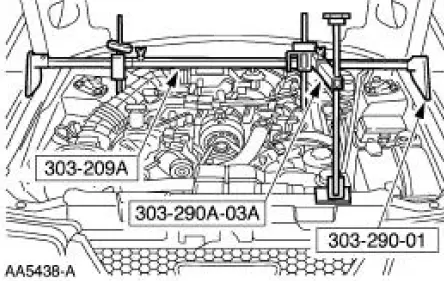

6. Install the special tool.

7. Install the special tool.

8. Raise and support the vehicle.

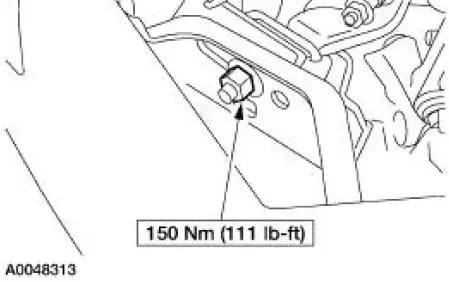

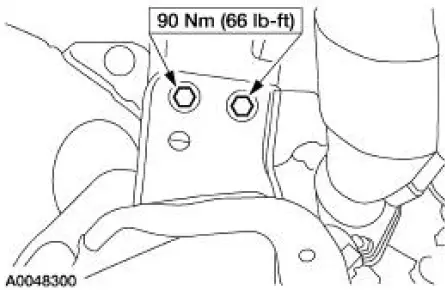

9. Remove the two engine mount nuts.

10. Lower the vehicle.

11. Using the special tool, raise and support the engine.

12. Raise the vehicle.

13. Support the front subframe.

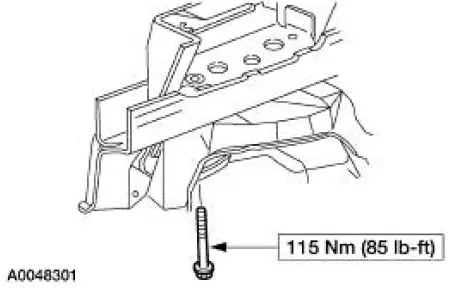

14. Remove the four front subframe lower bolts.

15. Remove the four front subframe upper bolts.

16. NOTE: Two technicians are needed to carry out this step.

Lower and remove the front subframe.

Front Subframe - 3.8L Engine

Front Subframe - 3.8L Engine

Special Tool(s)

3-Bar Engine Support Kit

303-F072

Lifting Bracket Set, Engine

303-D095 (D94L-6001-A) (014-

00792)

Removal and Installation

All vehicles

1. Remove the st ...

Front Subframe - 4.6L (4V) Engine

Front Subframe - 4.6L (4V) Engine

Special Tool(s)

3-Bar Engine Support Kit

303-F072

Lifting Bracket, Engine

303-D088 (D93P-6001-A2)

Removal and Installation

All vehicles

1. Remove the steering gear. For a ...

Other materials:

Pinpoint Tests - OSC Equipped Vehicles

Special Tool(s)

Breakout Box, EEC-V Control

System

418-049 (T94L-50-EEC-V) or

equivalent

MLP-TR Cable

418-F107 (007-00111) or

equivalent

Worldwide Diagnostic System

(WDS)

418-F224

New Generation STAR (NGS)

T ...

Countershaft Bearing

Special Tool(s)

Bearing Replacer

308-061 (T77J-7025-L)

Front Bearing Replacer

308-062 (T77J-7025-M)

Mainshaft Front Bearing

Replacer

308-081 (T82T-7003-DH)

Pinion Bearing Cone Remover

205-D002 (D79L-4621 ...

Heated seats

WARNING: Persons who are unable to feel pain to the skin

because of advanced age, chronic illness, diabetes, spinal cord

injury, medication, alcohol use, exhaustion, or other physical conditions,

must exercise care when using the seat heater. The seat heater m ...