Ford Mustang (1999-2004) Service Manual: Countershaft Bearing

Special Tool(s)

|

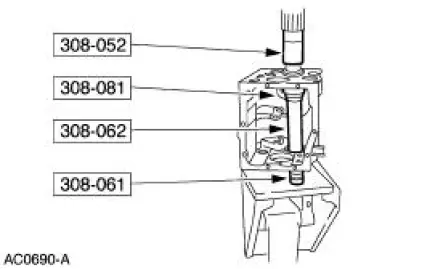

Bearing Replacer 308-061 (T77J-7025-L) |

|

Front Bearing Replacer 308-062 (T77J-7025-M) |

|

Mainshaft Front Bearing Replacer 308-081 (T82T-7003-DH) |

|

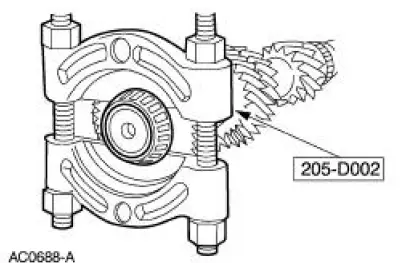

Pinion Bearing Cone Remover 205-D002 (D79L-4621-A) or Equivalent |

|

Pinion Bearing Cone Replacer 205-011 (T57L-4621-B) |

|

Remover and Replacer Tube 308-024 (T75L-7025-B) |

|

Remover and Replacer Tube 308-052 (T77J-7025-B) |

Disassembly

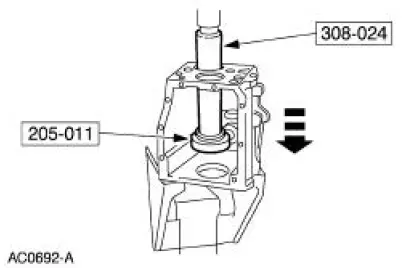

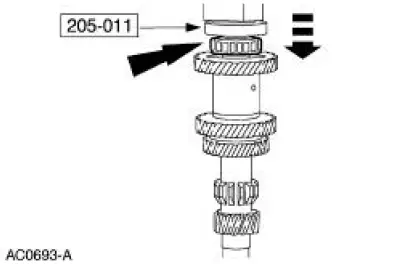

1. Using the special tool and a press, remove the countershaft bearing assembly (7F431).

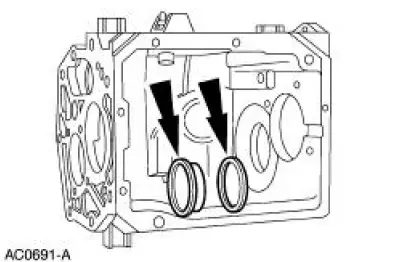

2. CAUTION: Failure to correctly support the case (7005) during bearing race removal will result in permanent distortion of the case.

NOTE: Remove the front countershaft bearing race only if damaged or worn.

Using the special tools and a press, remove the bearing race and the countershaft front bearing seal (7693).

Assembly

NOTE: Position the countershaft in the transmission case before installing the rear countershaft bearing.

1. Install the countershaft front bearing seal on the bearing race.

2. Coat the outside diameter of the bearing race with sealer.

- Use Threadlock and Sealer E0AZ-19554-AA or equivalent meeting Ford specification WSK-M2G351-5A.

3. CAUTION: Failure to correctly support the case during bearing race installation will result in permanent distortion of the case.

Using the special tools and a press, install the bearing race.

4. Using the special tool and a press, install the front countershaft bearing.

Output Shaft

Output Shaft

Special Tool(s)

Pinion Bearing Cone Remove

205-D002 (D79L-4621-A) or

Equivalent

Spiral Snap Ring Replacer

308-096 (T85P-7025-A)

Disassembly

1. Using the special tool a ...

Synchronizers

Synchronizers

Disassembly

NOTE: This procedure applies to all synchronizer assemblies

(7124). The synchronizers are slightly

different in design. Notation is made where procedural differences occur.

1. On the ...

Other materials:

Removal

1. Remove brake master cylinder filler cap (2162). Check brake fluid

level in brake master cylinder

reservoir (2K478). Remove fluid until brake master cylinder reservoir is

half full.

2. Raise and support the vehicle.

3. Remove the wheel and ...

Extension Housing Seal and Gasket

Special Tool(s)

Slide Hammer

100-001 (T50T-100-A)

Installer, Transmission

Extension Housing Fluid Seal

308-002 (T61L-7657-A)

Remover, Transmission Fluid

Seal

307-048 (T74P-77248-A)

Removal

1. Drain the transmiss ...

Fuel consumption

Filling the Tank

The advertised capacity is the indicated capacity and the empty reserve

combined. Indicated capacity is the difference in the amount of fuel in a

full tank and a tank when the fuel gauge indicates empty. Empty reserve

is the amount of fuel in ...