Ford Mustang (1999-2004) Service Manual: Glass, Frames and Mechanisms (Description and Operation)

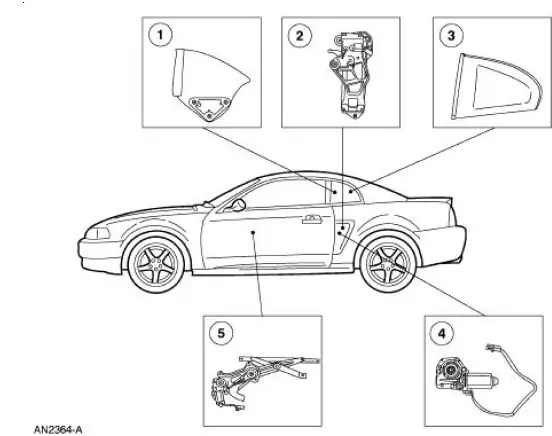

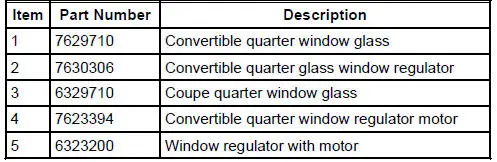

Component Location

Windshield Glass

The windshield exterior mouldings are installed with the windshield glass. The windshield exterior mouldings cannot be replaced without removal of the windshield.

Window Regulator Control Switch

Power windows are standard on all models. On coupe models, only the front door window glass can be raised or lowered. The quarter window glass is fixed. On the convertible models, all four windows can be raised or lowered. On all models, the window regulator control switches are available only to the front seat passengers. There are no window regulator controls for the back seat passengers.

Quarter window glass operations are controlled by the driver window regulator control switch.

Window, One-Touch Down

The LH window one-touch down feature is activated by momentarily pressing the driver window regulator control switch to the down position. This allows the front door window glass to move downward until it is fully lowered. Momentarily pressing the window regulator control switch while the window glass is moving downward will stop the front door window glass.

Window Glass, Door

The bottom of the door window glass is mounted on a slider bracket which is part of the front door window regulator. Door window glass bracket spacers provide attachment points for the door window glass and prevent direct contact between the slider bracket and the door window glass.

Window Glass, Quarter

The rear quarter window glasses on convertible models are driven by a window regulator motor and guide assembly.

Window Glass, Rear

On the coupe, the rear window upper garnish mouldings are installed with the rear window glass. The rear window upper garnish mouldings cannot be replaced without removing the rear window glass.

Glass, Frames and Mechanisms

Glass, Frames and Mechanisms

WINDOW REGULATOR ELECTRIC DRIVE

CURRENT DRAW

General Specifications

Torque Specifications

...

Glass, Frames and Mechanisms (Diagnosis and Testing)

Glass, Frames and Mechanisms (Diagnosis and Testing)

Refer to Wiring Diagrams Cell 100 , Power Windows for schematic and

connector information.

Refer to Wiring Diagrams Cell 56 , Rear Window Defrost for schematic and

connector information.

Specia ...

Other materials:

Removal

1. Disconnect the battery ground cable. For additional information, refer to

Section.

2. Drain the cooling system. For additional information, refer to Section.

3. Recover the refrigerant. For additional information, refer to Section.

4. Remove the air cle ...

Ignition Lock Cylinder - Functional

Removal and Installation

1. Disconnect the battery ground cable. For additional information,

refer to Section.

2. Remove the ignition switch lock cylinder (11582).

1. Insert the ignition key and turn to the RUN position.

2. Using a 1/8-inch d ...

Motor - Windshield Wiper

Removal

CAUTION: The internal permanent magnets used in the windshield

wiper motor are made

of a glass-like material. To avoid damaging the magnets, do not strike

the motor with a hammer

or any other object.

NOTE: The windshield wiper motor is n ...