Ford Mustang (1999-2004) Service Manual: Push Rods - Inspection

1. CAUTION: Do not attempt to straighten push rods.

Check the ends of the push rods for nicks, grooves, roughness or excessive wear. Install new push rods as necessary. Refer to the appropriate section in Group 303 for the procedure.

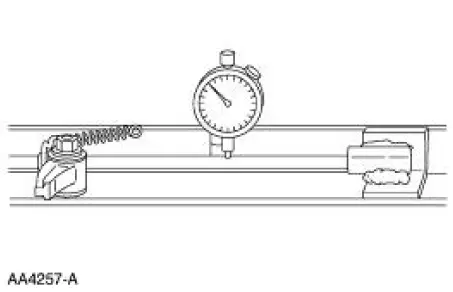

- The push rods can be checked for straightness while they are installed in the engine by rotating them with the valve closed.

- They also can be checked using a Dial Indicator with Bracketry.

2. If the push rod is bent beyond specifications, install a new push rod. Refer to the appropriate section in Group 303 for the procedure.

Camshaft Journal -Diameter

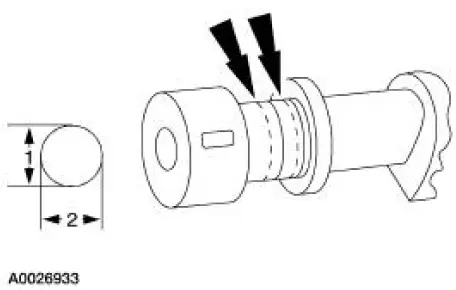

1. Measure each camshaft journal diameter in two directions.

- If out of specification, install new components as necessary. Refer to the appropriate section in Group 303 for the procedure.

Camshaft Journal -Clearance, Push Rod Engines, Micrometer Method

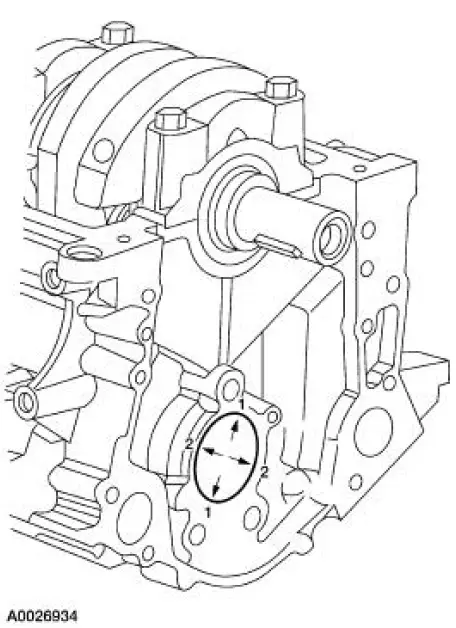

1. NOTE: The camshaft journals must meet specifications before checking camshaft journal clearance.

Measure each camshaft bearing (6261) in two directions.

- Subtract the camshaft journal diameter from the camshaft bearing diameter.

Rocker Arms - Inspection

Rocker Arms - Inspection

CAUTION: Do not attempt to true surfaces by grinding. Check the

rocker arm pad, side

rails and seat for excessive wear, cracks, nicks or burrs. Check the rocker

arm seat bolt for

stripped or bro ...

Camshaft Journal - Clearance, Plastigage Method

Camshaft Journal - Clearance, Plastigage Method

Special Tool(s)

Plastigage

303-D031 (D81L-6002-B) or

equivalent

NOTE: The camshaft journals must meet specifications before checking

camshaft journal clearance.

1. Remove the camsh ...

Other materials:

Jump-starting the vehicle

WARNING: The gases around the battery can explode if exposed

to flames, sparks, or lit cigarettes. An explosion could result in

injury or vehicle damage.

WARNING: Batteries contain sulfuric acid which can burn skin,

eyes and clothing, if contacted.

Do not atte ...

Pinpoint Tests

CAUTION: Do not make jumper connections except as directed.

Incorrect connections

may damage the voltage regulator test terminals, fuses, or fuse links.

CAUTION: Do not allow any metal object to come in contact with the

generator housing

and inter ...

Removal

CAUTION: Since the engine is not free-wheeling, timing procedures must

be followed

exactly or piston and valve damage can occur.

1. Remove the engine front cover. For additional information, refer to Engine

Front Cover in this

section.

2. Remove the cranksh ...