Ford Mustang (1999-2004) Service Manual: Parking, Rear and License Lamps

Refer to Wiring Diagrams Cell 92 , Exterior for schematic and connector information.

Special Tool(s)

|

73 III Automotive Meter or equivalent 105-R0057 |

Inspection and Verification

1. Verify the customer concern by operating the parking lamps.

2. Visually inspect for the following obvious signs of mechanical and electrical damage.

Visual Inspection Chart

| Mechanical |

Electrical |

|

|

3. If the concern is not visually evident, determine the symptom and proceed to Symptom Chart.

Symptom Chart

| Condition | Possible Sources | Action |

|

|

|

|

|

|

|

|

|

Pinpoint Tests

PINPOINT TEST L: THE PARKING, REAR OR LICENSE LAMPS ARE INOPERATIVE

| Test Step | Result / Action to Take |

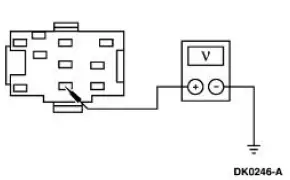

| L1 CHECK THE VOLTAGE TO THE HEADLAMP SWITCH | Yes GO to L2 . No REPAIR the circuit. TEST the system for normal operation. |

|

|

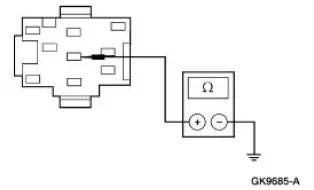

| L2 CHECK CIRCUIT 14 (BN) FOR OPEN | Yes INSTALL a new headlamp switch; REFER to Lamp Switch-Headlamp . TEST the system for normal operation. No REPAIR the circuit. TEST the system for normal operation. |

|

PINPOINT TEST M: ONE OR MORE PARKING, REAR OR LICENSE LAMP(S) IS INOPERATIVE

| Test Step | Result / Action to Take |

| M1 CHECK THE VOLTAGE TO THE INOPERATIVE LAMP(S) | Yes REPAIR Circuit 1205 (BK) for an open. TEST the system for normal operation. No REPAIR the circuit. TEST the system for normal operation |

|

PINPOINT TEST N: THE PARKING, REAR OR LICENSE LAMPS ARE ON CONTINUOUSLY

| Test Step | Result / Action to Take |

| N1 CHECK THE HEADLAMP SWITCH | Yes REPAIR Circuit 14 (BN) for a short to battery. TEST the system for normal operation. No INSTALL a new headlamp switch; REFER to Lamp Switch-Headlamp . TEST the system for normal operation |

|

Turn Signal and Hazard Lamps

Turn Signal and Hazard Lamps

Refer to Wiring Diagrams Cell 90 , Turn/Stop/Hazard Lamps for schematic

and connector information.

Special Tool(s)

73 III Automotive Meter

105-R0057 or equivalent

Inspection and Ver ...

Fog Lamps

Fog Lamps

Refer to Wiring Diagrams Cell 86 , Fog Lamps for schematic and connector

information.

Special Tool(s)

73 III Automotive Meter or

equivalent

105-R0057

Principles of Operation

The f ...

Other materials:

Information contained on the tire sidewall

Both U.S. and Canada Federal regulations require tire manufacturers

to place standardized information on the sidewall of all tires. This

information identifies and describes the fundamental characteristics of

the tire and also provides a U.S. DOT Tire Identifi ...

Instrument Cluster (Removal and Installation)

Removal and Installation

All vehicles

1. CAUTION: Electronic modules are sensitive to electrical

charges. If exposed to

these charges, damage may result.

Disconnect the battery ground cable. For additional information, refer

to Section.

2. Re ...

Vehicle Identification Number (VIN) Locator

The vehicle identification number (VIN) is a seventeen-digit alphanumeric

code. The VIN is stamped

on a metal tab riveted to the instrument panel, top upper left of the dash. The

VIN number is also found

on the vehicle certification (VC) label.

...