Ford Mustang (1999-2004) Service Manual: Pinpoint Tests

PINPOINT TEST A: THE BRAKES PULL OR DRIFT

| Test Step | Result / Action to Take |

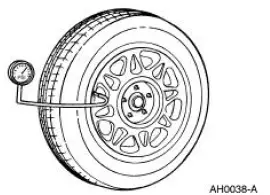

| A1 CHECK THE TIRES | Yes GO to A2 . No CORRECT as necessary. RETEST for normal operation. |

NOTE: Check tire pressure with the brakes off.

|

|

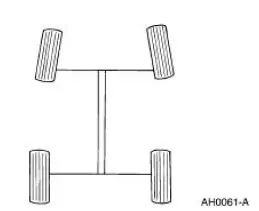

| A2 CHECK THE ALIGNMENT | Yes GO to A3 . No CORRECT alignment as necessary. RETEST for correct operation. |

|

|

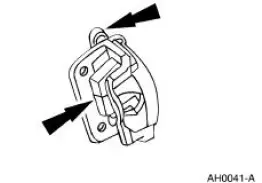

| A3 CHECK THE DISC BRAKE COMPONENTS | Yes GO to A4 . No REPAIR or INSTALL new components as necessary. RETEST for normal operation. |

|

|

| A4 ROAD TEST THE VEHICLE | Yes REPAIR or INSTALL new front disc brake caliper or anchor plate guide pins on the side opposite to the direction of the drift or pull. No REPAIR or INSTALL new front disc brake caliper or anchor plate guide pins on the side of the vehicle in the direction of the drift or pull. |

|

PINPOINT TEST B: THE RED BRAKE WARNING INDICATOR IS ALWAYS ON

| Test Step | Result / Action to Take |

| B1 CHECK THE BRAKE MASTER CYLINDER FLUID LEVEL SWITCH | Yes GO to B2 . No INSTALL a new brake master cylinder reservoir. TEST the system for normal operation. |

|

|

| B2 CHECK PARKING BRAKE SWITCH | Yes GO to B3 . No INSTALL a new parking brake switch. TEST the system for normal operation. |

|

|

| B3 CHECK THE GEM | Yes REPAIR the GEM. TEST the system for normal operation. No For vehicles without Daytime Running Lights (DRL), GO to B4 . For vehicles with DRL, GO to B5 . |

|

|

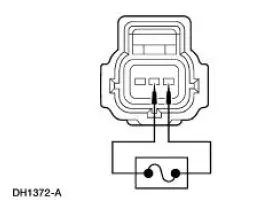

| B4 CHECK CIRCUITS 977 (VT/WH), 22 (LB/BK) AND 128 (VT/YE) | Yes REPAIR the ground short in circuit 128 (VT/YE). TEST the system for normal operation. No REPAIR the ground short in circuit 977 (VT/WH) or circuit 22 (LB/BK). TEST the system for normal operation. |

|

|

| B5 CHECK CIRCUIT 128 (VT/YE) | Yes GO to B6 . No REPAIR the ground short in circuit 128 (VT/YE). TEST the system for normal operation. |

|

|

| B6 CHECK DAYTIME RUNNING LIGHTS (DRL) MODULE | Yes REPAIR the DRL module. TEST the system for normal operation. No REPAIR the ground short in circuit 22 (LB/BK) or 977 (VT/WH). TEST the system for normal operation. |

|

PINPOINT TEST C: BRAKE LOCKUP DURING LIGHT BRAKE PEDAL FORCE

| Test Step | Result / Action to Take |

| C1 INSPECT THE TIRES | Yes GO to C2 . No CORRECT as necessary. RETEST for normal operation. |

|

|

| C2 CHECK THE BRAKE CALIPER COMPONENTS | Yes GO to C3 . No CORRECT as necessary. RETEST for normal operation. |

|

|

| C3 CHECK THE PROPORTIONING VALVE | Yes INSPECT the disc brake calipers and INSTALL new calipers as necessary. RETEST for normal operation. No INSTALL a new proportioning valve. RETEST for normal operation. |

|

PINPOINT TEST D: EXCESSIVE/ERRATIC BRAKE PEDAL TRAVEL

| Test Step | Result / Action to Take |

| D1 CHECK FOR SPONGY PEDAL | Yes BLEED the brake system. REFER to Bleeding - System in this section. RETEST for normal operation. No GO to D2 . |

|

|

| D2 CHECK THE BRAKE PEDAL | Yes GO to D3 . No REPAIR or INSTALL a new brake pedal as necessary. RETEST for normal operation. |

|

|

| D3 CHECK THE BRAKE COMPONENTS | Yes GO to D4 . No REPAIR or INSTALL new components as necessary. RETEST for normal operation. |

|

|

| D4 CHECK THE BOOSTER AND MASTER CYLINDER | Yes INSPECT the front wheel bearings for wear, damage and correct installation and the rear axle end play. CORRECT as necessary. RETEST for normal operation. No CORRECT as necessary. RETEST for normal operation. |

|

PINPOINT TEST E: HYDRO-BOOST, NO POWER ASSIST

| Test Step | Result / Action to Take |

| E1 CHECK FLUID LEVEL IN POWER STEERING PUMP | Yes GO to E2 . No CHECK for leakage of power steering fluid. ADD fluid as necessary. |

|

|

| E2 CHECK ACCESSORY DRIVE BELT | Yes GO to E3 . No INSTALL a new accessory drive belt. |

|

|

| E3 CHECK POWER STEERING HOSES | Yes GO to E4 . No INSTALL new hoses as necessary. |

|

|

| E4 CHECK BRAKE PEDAL LINKAGE | Yes GO to E5 . No INSTALL new pedal linkage as necessary. |

|

|

| E5 CHECK POWER STEERING PUMP SPEED | Yes GO to E6 . No SET engine idle speed to specification. REFER to Powertrain Control/Emissions Diagnosis (PC/ED) manual. |

|

|

| E6 CHECK FOR PLUGGED RETURN HOSE | Yes INSTALL a new power steering return hose. No GO to E7 . |

|

|

| E7 CHECK POWER STEERING PUMP FLOW AND RELIEF | Yes INSTALL a new power brake hydro-boost unit. No INSTALL a new power steering pump. |

|

PINPOINT TEST F: HYDRO-BOOST ERRATIC OPERATION, STICKS, BINDS OR GRABS

| Test Step | Result / Action to Take |

| F1 CHECK SUPPLY HOSE | Yes REMOVE obstructions or INSTALL a new hose. No GO to F2 . |

|

|

| F2 CHECK BOOSTER OPERATION | Yes System OK. No INSTALL a new hydro-boost assembly. |

|

PINPOINT TEST G: HYDRO-BOOST BRAKE SYSTEM OPERATION SUSPECT

| Test Step | Result / Action to Take |

| G1 CHECK BASIC OPERATION | Yes Hydro-boost is OK. No GO to G2 . |

|

|

| G2 CHECK FOR HYDRAULIC BRAKE LEAK | Yes GO to G3 . No GO to G4 . |

|

|

| G3 CHECK FOR LEAKS - BRAKE FLUID LINES | Yes COMPLETE master cylinder By-Pass Condition Test in this section. No INSTALL new hoses and lines as necessary. |

|

|

| G4 CHECK HYDRO-BOOST CONNECTIONS | Yes GO to G5 . No REPAIR or INSTALL new hose and connections as necessary. |

|

|

| G5 CHECK FOR HYDRO-BOOST LEAK | Yes GO to G6 . No INSTALL a new hydro-boost unit. |

|

|

| G6 CHECK RESERVE RETENTION | Yes Hydro-boost unit is OK. No INSTALL a new hydro-boost unit. |

|

Symptom Chart

Symptom Chart

Condition

Possible Sources

Action

The Brakes Pull or

Drift

Tire air pressure.

Wheel alignment.

Brake pads.

Brake components.

Suspension

component ...

Component Tests

Component Tests

Brake Booster

1. Check the hydraulic brake system for leaks or insufficient fluid.

2. With the transmission (7003) in NEUTRAL, stop the engine (6007) and

apply the parking brake

control (278 ...

Other materials:

Input Shaft and Bearing

Special Tool(s)

Input Shaft Seal Replacer

308-220 (T94P-7025-AH)

Pinion Bearing Cone Remover

205-D002 (D79L-4621-A) or

Equivalent

Disassembly

1. Using the special tool and a press, remove the input bearing (7025).

2. Remove t ...

Refrigerant System Tests

Special Tool(s)

R-134a Manifold Gauge Set

176-R032A or equivalent

1. Connect the R-134a Manifold Gauge Set. For additional information, refer

to Manifold Gauge

Set Connection in this section.

2. Adjust the climate controls for maximum cooling ...

Accelerator Cable Bracket - 4.6L (2V)

Removal and Installation

1. Disconnect the speed control cable from the throttle body and the bracket.

For additional

information, refer to Section.

2. Disconnect the accelerator cable from the throttle body by rotating the

throttle body full open

and align ...