Ford Mustang (1999-2004) Service Manual: Piston

Material

| Item | Specification |

| Super Premium SAE 5W-20 Motor Oil XO-5W20-QSP or equivalent | WSS-M2C153- H |

Disassembly

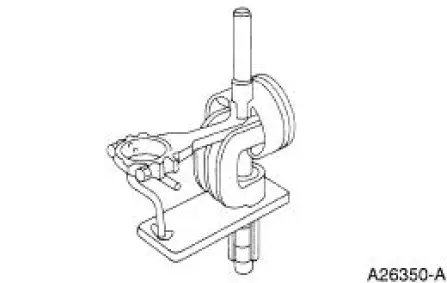

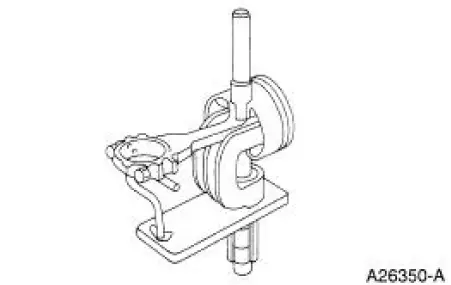

1. Press the piston pin out of the connecting rod and piston assembly.

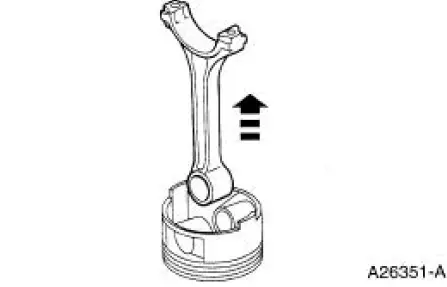

2. Remove the connecting rod from the piston.

3. Clean and inspect the piston and connecting rod. For additional information, refer to Section.

Assembly

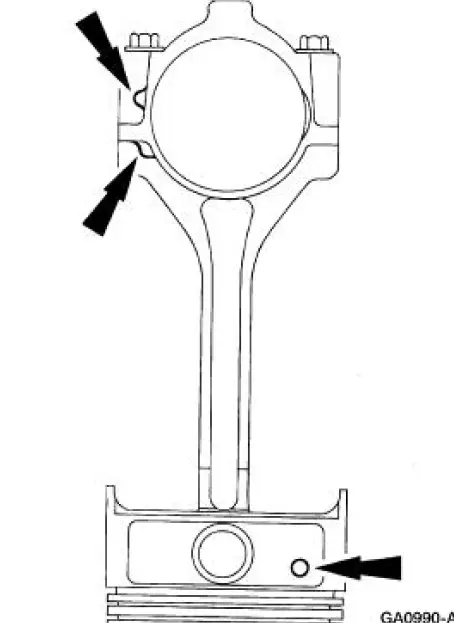

1. NOTE: Connecting rod must be installed into piston with identification markings toward front.

Position the connecting rod in the piston.

2. Press the piston into the piston and connecting rod assembly.

3. Install the piston rings.

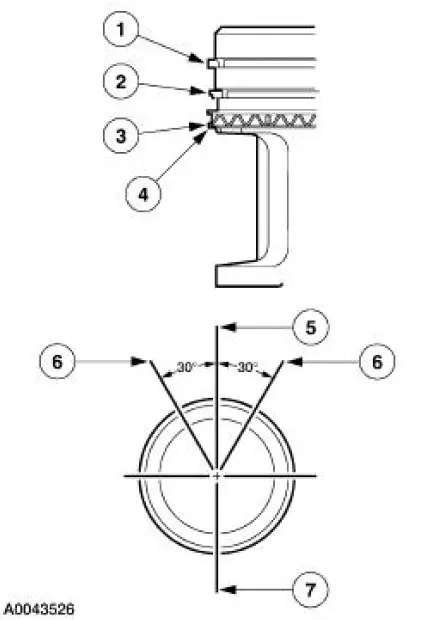

1. Using a suitable ring expander tool install the upper compression ring with the top side identification mark towards the dome.

2. Using a suitable ring expander tool install the lower compression ring with the top side identification mark towards the dome.

3. NOTE: Assemble with end gaps up.

Using a suitable tool install the piston oil control segment ring spacer.

4. NOTE: Install one segment ring above and one segment ring below the spacer.

Using a suitable tool install the piston oil control segment rings.

5. Orient the upper compression ring gap to the center line at the rear of the piston, parallel to the wrist pin bore.

6. Orient the oil control ring gaps as shown.

7. Orient the expander ring gap and lower compression ring gap as shown.

Cylinder Head (Disassembly and Assembly of Subassemblies)

Cylinder Head (Disassembly and Assembly of Subassemblies)

Special Tool(s)

Compressor, Valve Spring

303-381(T91P-6565-A)

Compressor Spacer, Valve

Spring

303-382 (T91P-6565-AH)

Installer, Valve Stem Oil Seal

303-383 ( ...

Engine (Assembly)

Engine (Assembly)

Special Tool(s)

Guides, Connecting Rod

303-442 (T93P-6136-A)

Installer, Crankshaft Rear Oil

Seal

303-518 (T95P-6701-DH)

Installer, Crankshaft Rear Oil

Seal

...

Other materials:

EGR System Components

The EGR system returns a portion of the exhaust gas to the intake manifold to

reduce the combustion

temperature. This results in lower nitrous oxide formation.

The powertrain control module (PCM) controls the EGR vacuum regulator solenoid .

The EG ...

Removal

1. Disconnect the battery ground cable. For additional information, refer to

Section.

2. Drain the cooling system. For additional information, refer to Section.

3. Recover the refrigerant. For additional information, refer to Section.

4. Remove the air cle ...

Removal

1. Disconnect the battery ground cable. For additional information, refer

to Section.

2. Remove the engine air cleaner outlet pipe. For additional information,

refer to Section.

3. Disconnect the vacuum hose and the idle air control (IAC) valve

elect ...