Ford Mustang (1999-2004) Service Manual: Removal

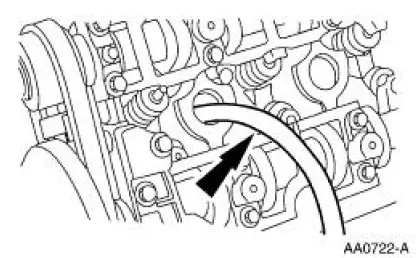

1. Remove the roller followers. For additional information, refer to Roller Followers in this section.

2. Remove the spark plugs. For additional information, refer to Section .

3. Position the piston of the cylinder being serviced at the bottom of the stroke.

4. CAUTION: If air pressure has forced the piston to the bottom of the cylinder any loss of air pressure will allow the valve to fall into the cylinder. If air pressure must be removed support the valve prior to removal.

Use compressed air in the cylinder to hold both valves in position.

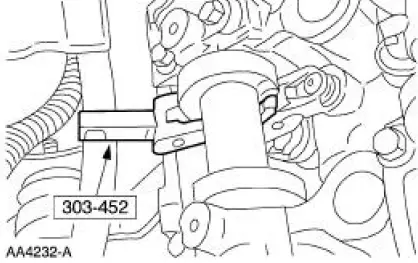

5. Using the special tool, compress the intake valve spring.

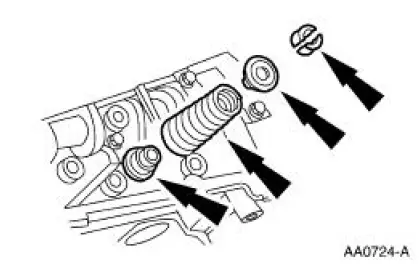

6. NOTE: Valve stem seals should be visually inspected if new seals are not installed.

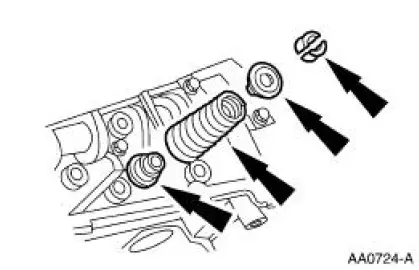

Remove the valve spring retainer keys, the valve spring retainer, the valve spring and the valve stem seal.

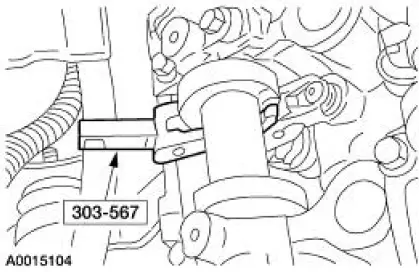

7. Using the special tool, compress the exhaust valve spring.

8. NOTE: Valve stem seals should be visually inspected if new seals are not installed.

Remove the valve spring retainer keys, the valve spring retainer, the valve spring and the valve stem seal.

Valve - Springs, Retainer and Valve Stem Seal

Valve - Springs, Retainer and Valve Stem Seal

Special Tool(s)

Compressor, Valve Spring

303-452 (T93P-6565-AR)

Installer, Valve Stem Oil Seal

303-383 (T91P-6571-A)

Compressor, Valve Spring

303-567 (T97P- ...

Installation

Installation

1. Using the special tools, install the new intake valve stem seals.

2. Using the special tools, install the new exhaust valve stem seals.

3. Install the Valve Spring Compressor Spacer between the ...

Other materials:

Suction Accumulator to Compressor Line - 4.6L

Material

Item

Specification

PAG Refrigerant Compressor

Oil (R-134a Systems)

F7AZ-19589-DA (Motorcraft YN-

12-C)

WSH-M1C231-

B

Removal and Installation

NOTE: Installation of a new suction accumulator is not required when

repairing the ...

Disassembly

1. Remove the retaining ring above fifth gear.

2. CAUTION: Hand tighten the special tool to prevent gear damage.

CAUTION: Support the output shaft while using the press to prevent

damage to the

shaft or gears.

Using the special tool, press fifth gear, the s ...

Pinpoint Tests

PINPOINT TEST A: THE BRAKES PULL OR DRIFT

Test Step

Result / Action to Take

A1 CHECK THE TIRES

YesGO to A2 .

No

CORRECT as necessary.

RETEST for normal

operation.

NOTE: Check tire pressure with the brakes off.

Check tires for u ...