Ford Mustang (1999-2004) Service Manual: Reversing Lamps

Refer to Wiring Diagrams Cell 93 , Backup Lamps for schematic and connector information.

Special Tool(s)

|

73III Automotive Meter or equivalent 105-R0057 |

Inspection and Verification

1. Verify the customer concern by operating the reversing lamps.

2. Visually inspect for obvious signs of mechanical and electrical damage; refer to the following chart:

Visual Inspection Chart

| Mechanical | Electrical |

|

|

3. If the concern is not visually evident, determine the symptom and proceed to Symptom Chart.

Symptom Chart

| Condition | Possible Sources | Action |

|

|

|

|

|

|

|

|

|

Pinpoint Tests

PINPOINT TEST R: THE REVERSING LAMPS ARE INOPERATIVE

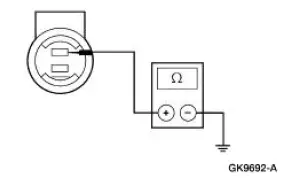

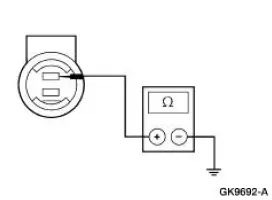

| Test Step | Result / Action to Take |

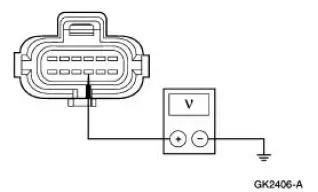

| R1 CHECK THE VOLTAGE TO THE DTR SENSOR (A/T) OR THE REVERSING LAMP SWITCH (M/T) | Yes GO to R2 . No REPAIR the circuit. TEST the system for normal operation. |

|

|

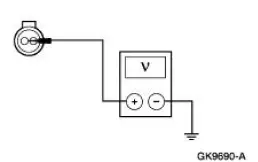

| R2 CHECK CIRCUIT 140 (BK/PK) FOR OPEN | Yes INSTALL a new DTR sensor (A/T) or reversing lamp switch (M/T); TEST the system for normal operation. No GO to R3 . |

|

|

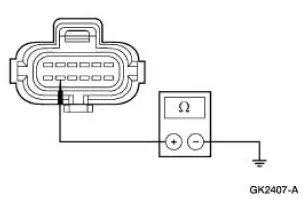

| R3 CHECK REVERSING LAMPS GROUND | Yes REPAIR Circuit 140 (BK/PK) for open. TEST the system for normal operation. No REPAIR the circuit. TEST the system for normal operation |

|

PINPOINT TEST S: THE INDIVIDUAL REVERSING LAMP IS INOPERATIVE

| Test Step | Result / Action to Take |

| S1 CHECK REVERSING LAMPS GROUND | Yes REPAIR Circuit 140 (BK/PK) for open. TEST the system for normal operation. No REPAIR the circuit. TEST the system for normal operation. |

|

PINPOINT TEST T: THE REVERSING LAMPS ARE ON CONTINUOUSLY

| Test Step | Result / Action to Take |

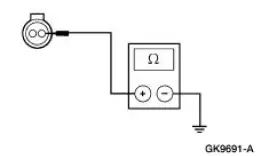

| T1 CHECK THE CONTINUITY OF THE DTR SENSOR (A/T) OR THE REVERSING LAMP SWITCH (M/T) | Yes REPAIR Circuit 140 (BK/PK) for short to battery. TEST the system for normal operation. No INSTALL a new DTR sensor (A/T) or reversing lamp switch (M/T); TEST the system for normal operation. |

|

Fog Lamps

Fog Lamps

Refer to Wiring Diagrams Cell 86 , Fog Lamps for schematic and connector

information.

Special Tool(s)

73 III Automotive Meter or

equivalent

105-R0057

Principles of Operation

The f ...

Headlamp Adjustment

Headlamp Adjustment

Headlamp Aiming

1. The headlamp aiming procedure depends on the type of beam pattern the

headlamp is

equipped with. Vehicles may come equipped with visual optical right (VOR),

visual optical lef ...

Other materials:

Installation

1. CAUTION: Timing chain procedures must be followed exactly or damage

to the

pistons or valves will result.

Compress the tensioner plunger, using a soft-jawed vise.

2. Install a retaining clip on the tensioner to hold the plunger in during

installation.

...

Muffler - 4.6L (4V)

Removal and Installation

1. Raise and support the vehicle. For additional information, refer to

Section.

2. NOTE: RH side shown, LH side similar.

Remove the dual converter assembly nuts.

3. Remove the RH exhaust hanger insulator (5260).

4. Remove the LH ...

Degas Bottle - 4.6L(2V) and 4.6L(4V)

Removal and Installation

1. Drain the engine coolant from the degas bottle only. For additional

information, refer to Cooling

System Draining, Filling and Bleeding in this section.

2. Disconnect the radiator vent hose.

3. Remove the degas bottle return hos ...