Ford Mustang (1999-2004) Service Manual: Installation

1. CAUTION: Timing chain procedures must be followed exactly or damage to the pistons or valves will result.

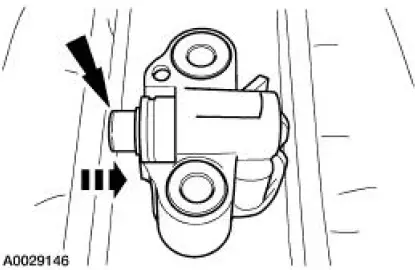

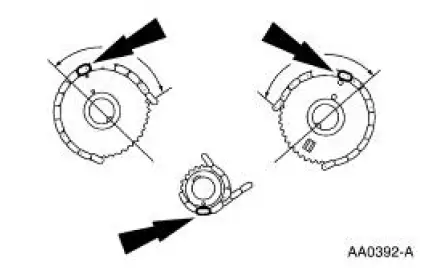

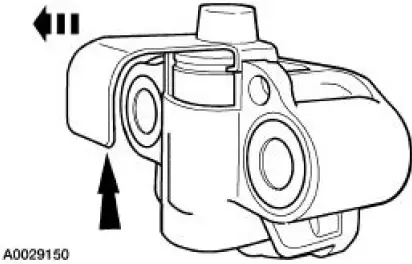

Compress the tensioner plunger, using a soft-jawed vise.

2. Install a retaining clip on the tensioner to hold the plunger in during installation.

- Remove the tensioner from the vise.

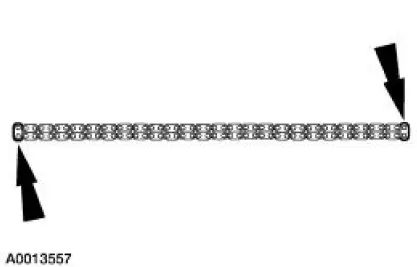

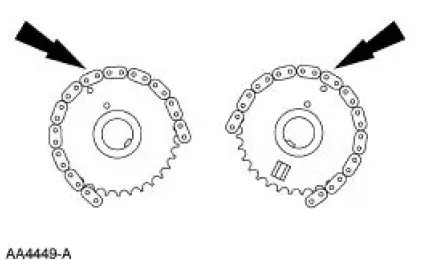

3. If the copper links are not visible, mark one link on one end and one link on the other end, and use as timing marks.

4. Install the timing chain guides.

5. Rotate the LH camshaft sprocket until the timing mark is approximately at the 12 o' clock position. Rotate the RH camshaft timing sprocket until the timing mark is approximately in the 11 o' clock position.

6. CAUTION: Unless otherwise instructed, at no time when the timing chains are removed and the cylinder heads are installed is the crankshaft or the camshaft to be rotated. Severe piston and valve damage will occur.

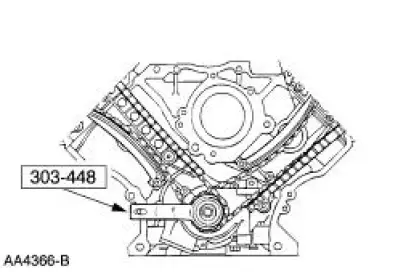

CAUTION: Rotate the crankshaft counterclockwise only. Do not rotate past position shown or severe piston or valve damage will occur.

Using the special tool, position the crankshaft.

7. Remove the special tool.

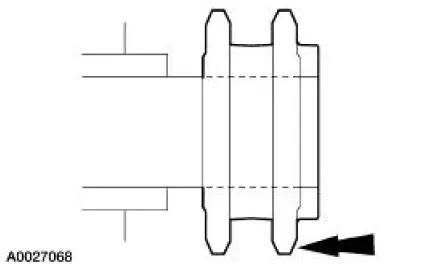

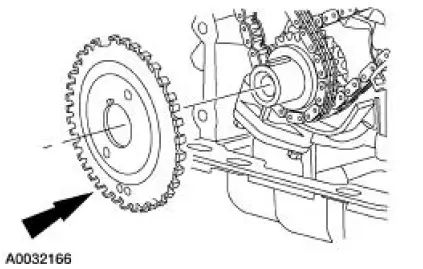

8. Install the crankshaft sprocket with the flange facing forward.

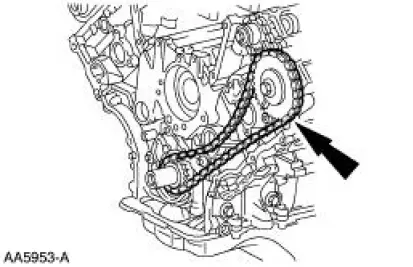

9. NOTE: LH timing chain shown; RH similar.

Install the LH timing chain onto the crankshaft sprocket, aligning the one copper link on the timing chain with the slot on the crankshaft sprocket.

10. Verify the camshaft sprocket to copper link alignment.

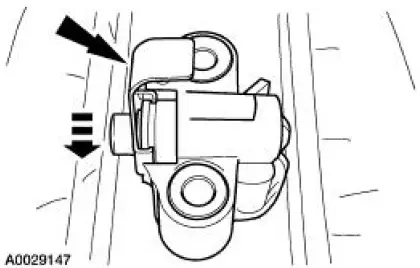

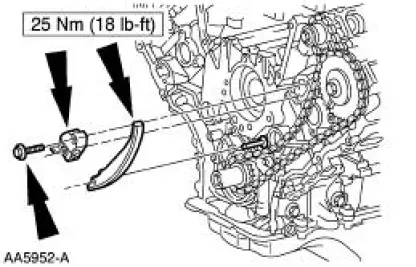

11. NOTE: LH shown; RH similar.

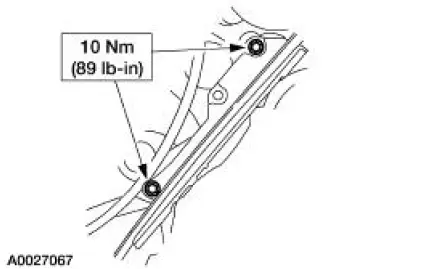

Position the tensioner arms and tensioners, and install the bolts.

12. Remove the retaining clips from the timing chain tensioners.

13. Position the crankshaft sensor ring on the crankshaft.

14. Install the engine front cover. For additional information, refer to Engine Front Cover in this section.

Removal

Removal

CAUTION: Since the engine is not free-wheeling, if the crankshaft or

the camshafts are

moved in any manner during removal and installation, the crankshaft and the

camshafts must

be re-synchronized.

...

Valve - Springs, Retainer and Valve Stem Seal

Valve - Springs, Retainer and Valve Stem Seal

Special Tool(s)

Compressor, Valve Spring

303-452 (T93P-6565-AR)

Installer, Valve Stem Oil Seal

303-383 (T91P-6571-A)

Compressor, Valve Spring

303-567 (T97P- ...

Other materials:

Multifunction Electronic Control Modules

Torque Specifications

Module Controlled Functions

The generic electronic module (GEM)(14B205) is the only multifunction

control module on this vehicle.

The GEM controls the following functions:

warning chimes and warning lamps

one-touch down ...

Spark Plug

Removal

1. Remove the ignition coil on plug. For additional information, refer to

Ignition Coil-Coil On Plug

in this section.

2. NOTE: Use compressed air to remove any foreign material from the

spark plug well before

removing the spark plugs (12405).

...

Pinpoint Tests

CAUTION: Be careful when probing the CJB, battery junction box (BJB)

or any

connectors. Damage will result to the connector receptacle if the probe or

terminal being used

is too large.

CAUTION: Electronic modules are sensitive to static electrical char ...