Ford Mustang (1999-2004) Service Manual: Starter Motor - 3.8L

Removal

WARNING: When servicing starter motor (11002) or carrying out other underhood work in the vicinity of the starter motor, be aware that the heavy gauge battery input lead at the starter solenoid (11390) is "electrically hot" at all times. A protective cap or boot is provided over this terminal that must be installed after servicing. Be sure to disconnect the battery negative cable before servicing the starter. Failure to follow these instructions may result in personal injury.

WARNING: When working in area of the starter motor, be careful to avoid touching hot exhaust components. Failure to follow these instructions may result in personal injury.

NOTE: When working on the starter system, make sure the anti-theft system is deactivated (if equipped.)

1. Disconnect the battery ground cable. For additional information, refer to Section.

2. Raise and support the vehicle. For additional information, refer to Section.

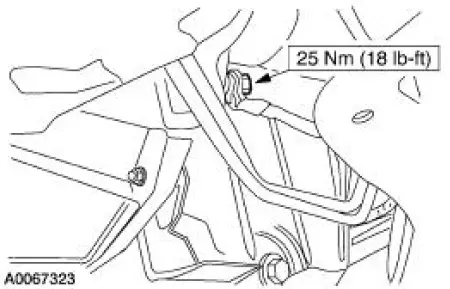

3. Remove the ground cable nut.

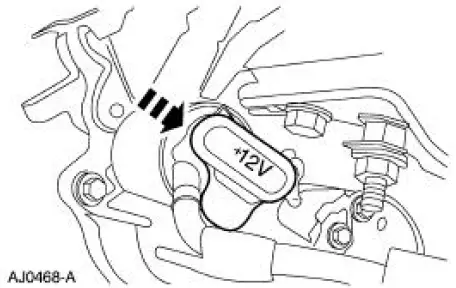

4. Remove the cap.

5. Remove the nuts and position aside the wires.

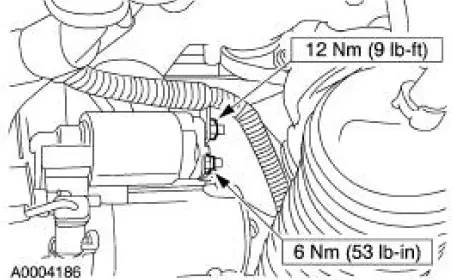

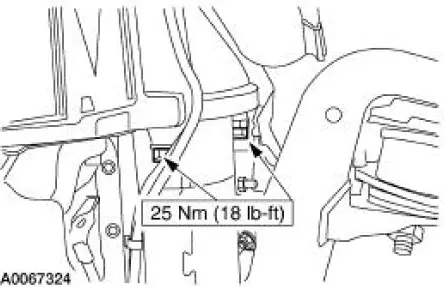

6. Remove the bolts and the starter motor.

Installation

1. To install, reverse the removal procedure.

Relay Switch

Relay Switch

1. Disconnect the battery ground cable. For additional information, refer

to Section.

2. Remove the power distribution box cover.

3. Remove the starter relay from the power distribution box.

I ...

Starter Motor - 4.6L

Starter Motor - 4.6L

Removal

WARNING: When servicing starter motor (11002) or carrying out other

underhood work in

the vicinity of the starter motor, be aware that the heavy gauge battery

input lead at the starter

...

Other materials:

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A

new part with

the same part number must be installed if installation becomes necessary. ...

Output State Control (OSC) Mode

Output State Control (OSC) allows the technician to take control of

certain parameters to function the

transmission. For example, OSC allows the technician to shift the

transmission only when he/she

commands a gear change. If the technician commands ...

Engine Front Cover

Material

Item

Specification

Metal Surface Cleaner

F4AZ-19A536-RA or equivalent

WSE-M5B392-

A

Silicone Gasket and Sealant

F7AZ-19554-EA or equivalent

WSE-M4G323-

A4

SAE 5W-30 Premium Synthetic

Blend Motor Oil

XO-5W30-QSP ...