Ford Mustang (1999-2004) Service Manual: Transmission (Assembly)

Special Tool(s)

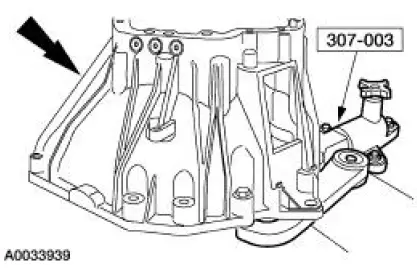

|

Dial Indicator Gauge with Holding Fixture 100-002 (TOOL-4201-C) or equivalent |

|

Holding Fixture, Transmission 307-003 (T57L-500-B) |

|

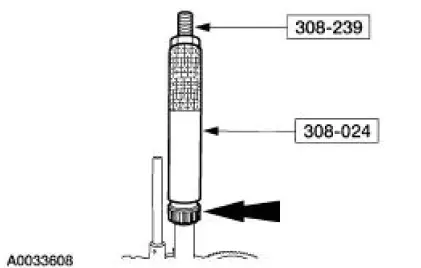

Remover/Installer, Bearing Tube 308-024 (T75L-7025-B) |

|

Replacer/Adapter 308-239 (T96P-7025-A) |

|

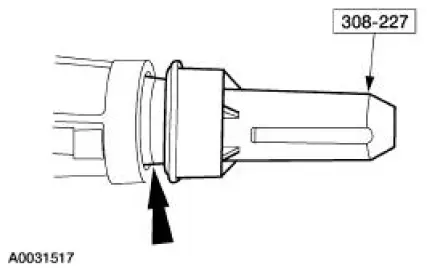

Installer, Transmission Extension Housing Oil Seal 308-227 (T94P-7657-A) |

Material

| Item | Specification |

| Motorcraft MERCON Multi- Purpose (ATF) Transmission Fluid XT-2-QDX | MERCON |

| Premium Long Life Grease XG-1-C, K or T | ESA-M1C75- B |

1. Lubricate all components with transmission fluid during assembly.

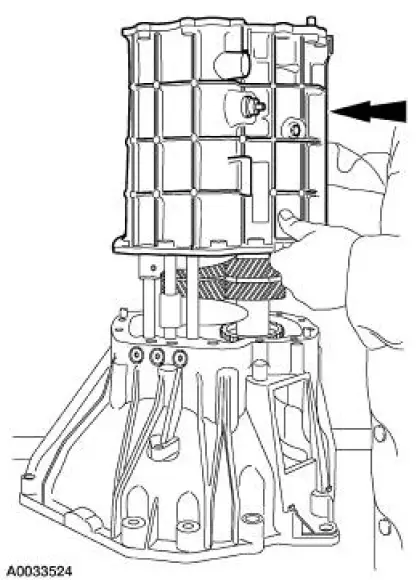

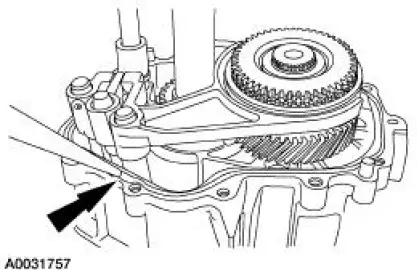

2. Attach the clutch housing to the special tool.

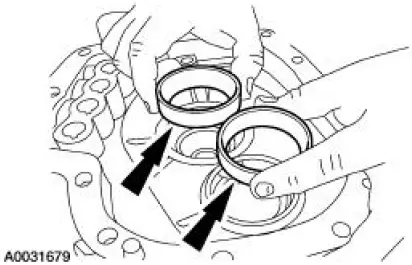

3. NOTE: If a new rear output shaft bearing was installed or a new rear countershaft bearing is being used, install new bearing cups.

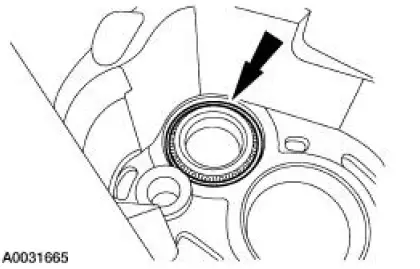

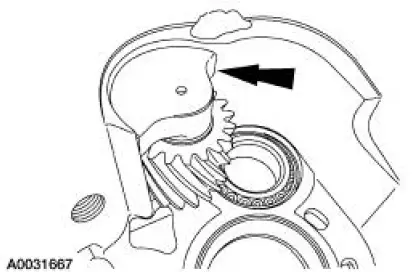

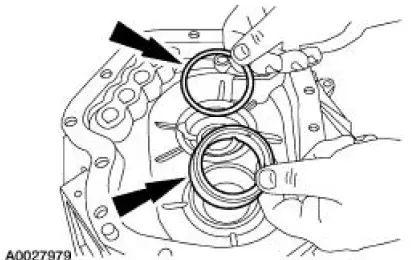

Install the rear countershaft bearing cup and the rear output shaft bearing cup.

- Lubricate the bearing cups and the shift rail bearing with petroleum jelly.

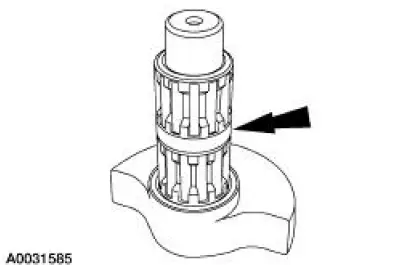

4. Install the rear countershaft bearing.

5. Install the reverse idler gear bearings and spacer on the shaft.

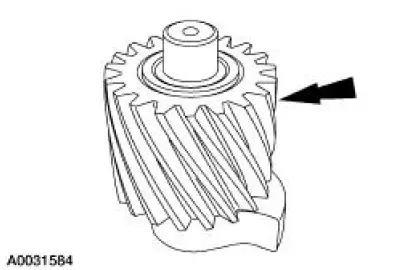

6. Install the reverse idler gear on the shaft.

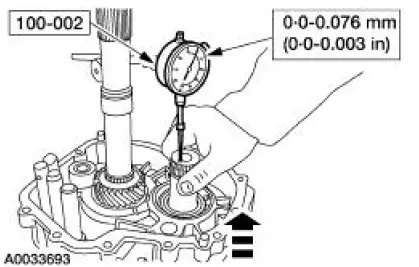

7. Install the reverse idler gear into the case.

8. Install a new seal on the reverse idler bolt, then install the bolt in the transmission case.

9. NOTE: If a new front input shaft bearing or front countershaft bearing was installed, install new bearing cups.

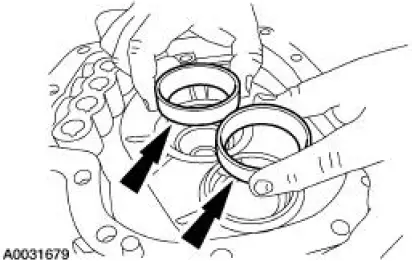

Install the front input shaft bearing cup and the front countershaft bearing cup. Do not install the shims at this time.

- Install the transmission main case.

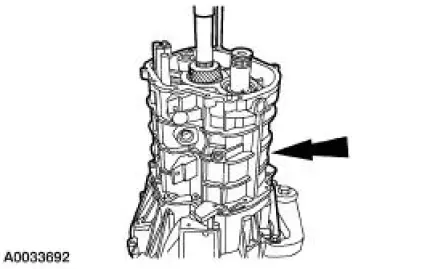

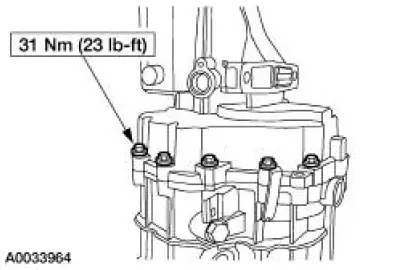

10. Install the input shaft.

11. Install the shift rails and shift forks on the mainshaft.

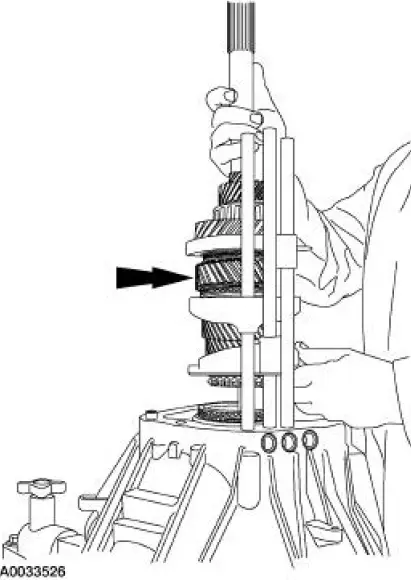

12. Install the mainshaft onto the clutch housing.

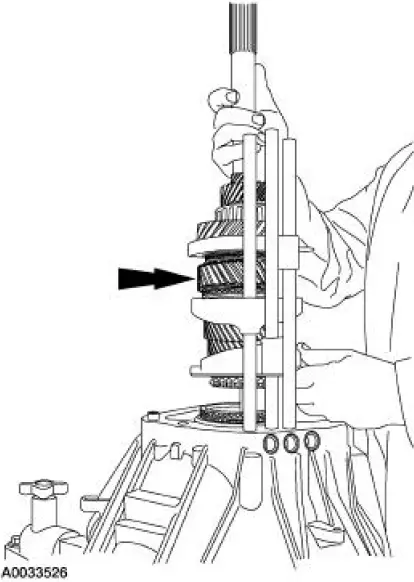

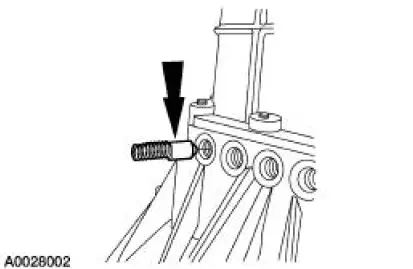

- The notches on the shift rail should be pointing upward.

- Align the shift rails in the bores.

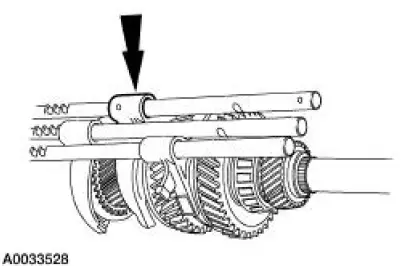

13. Install the countershaft.

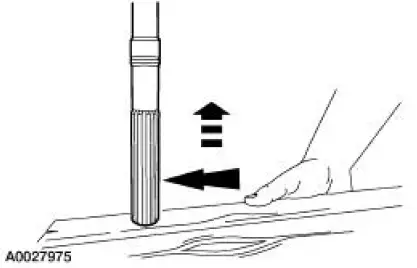

- Lift the mainshaft upward, tilt the countershaft and install.

14. Install the case with two opposing bolts.

15. NOTE: Rotate the transmission so that the input shaft is pointing upward.

NOTE: Rotate the input shaft to seat the bearings.

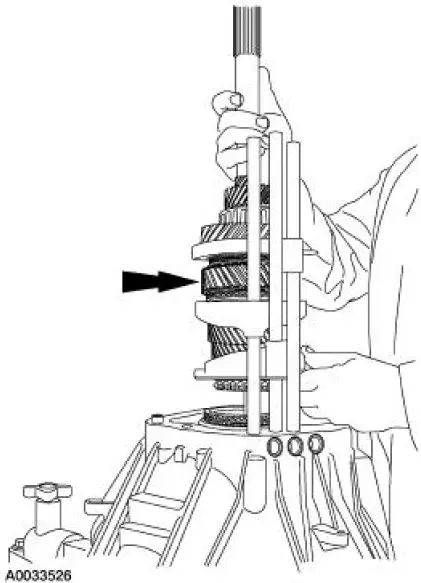

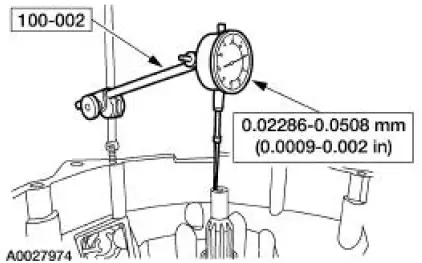

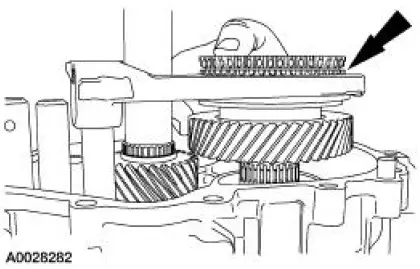

Using the special tools, measure the input shaft end play by applying an upward load on the output shaft. Record the measurement.

16. Rotate the transmission so that the input shaft is pointing downward.

17. NOTE: Rotate the countershaft to seat the bearings.

Using the special tools, measure the countershaft gear end play by pulling upward on the countershaft. Record the measurement.

18. Remove the two bolts and lift the transmission main case off.

19. Remove the countershaft.

20. Remove the mainshaft.

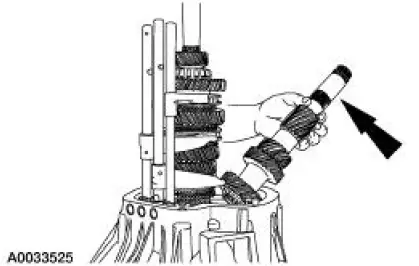

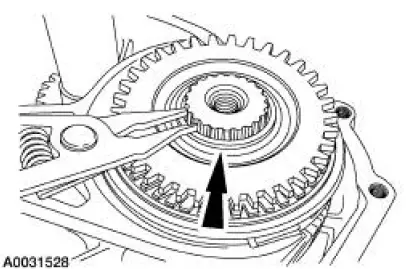

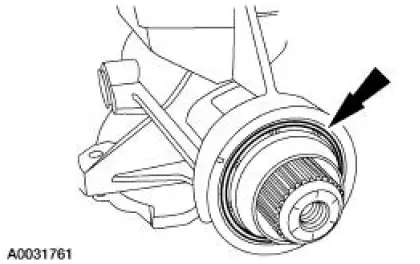

21. Remove the input shaft.

22. Remove the front input shaft bearing cup and the front countershaft bearing cup.

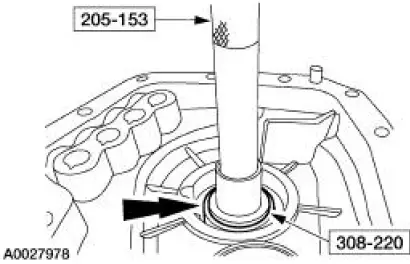

23. Using the special tools, install the new input shaft seal.

24. Using the recorded end play measurements, select and install the appropriate shims to achieve the correct end play.

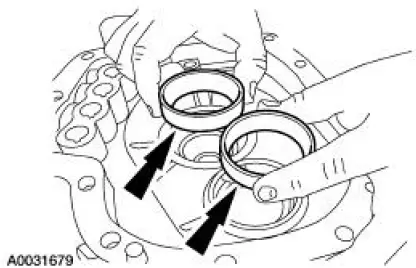

25. Install the front input shaft bearing cup and the front countershaft bearing cup.

26. Install the input shaft.

27. Install the mainshaft.

28. Install the countershaft.

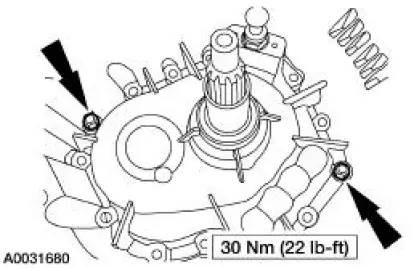

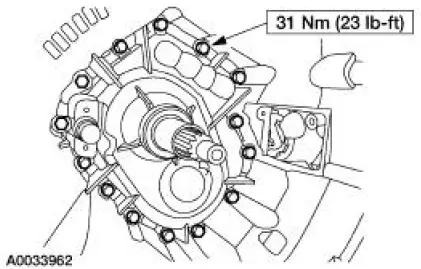

29. Clean the mating surfaces of the transmission main case and the clutch housing. Apply a bead of silicone rubber to the sealing surface on the clutch housing then install the transmission main case. Tighten the bolts in a star pattern.

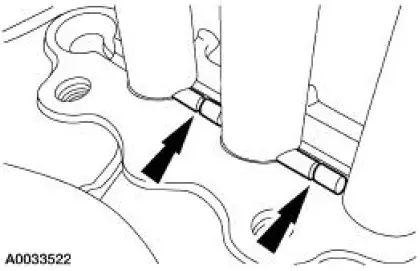

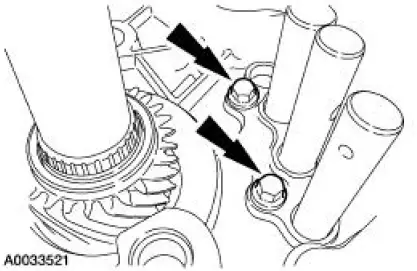

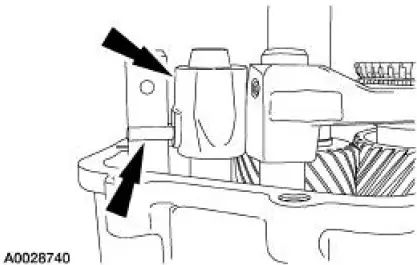

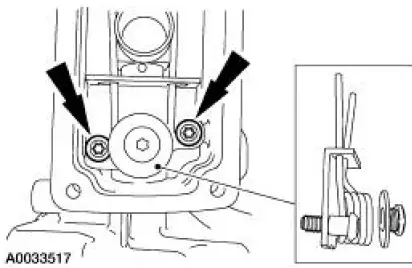

30. Install the lock pins.

31. Install the lock plate.

32. Install the detents and the detent springs.

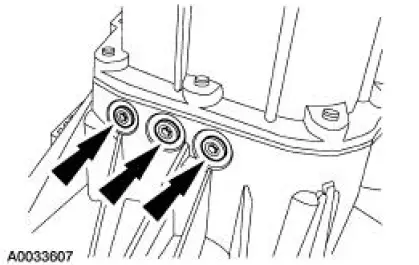

33. Install the detent plugs.

34. Install the check ball.

- Use petroleum jelly to hold the check ball in place.

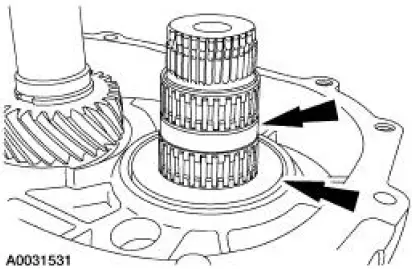

35. Install the thrust washer and the three-piece fifth gear needle bearing.

36. Install the synchronizer springs and inserts.

37. Install the sliding sleeve on the synchronizer hub.

- Align the pockets in the blocking ring with the struts in the synchronizer.

- The sliding sleeve is not reversible. Install the sleeve with the bevel edge away from the gear.

38. Install fifth gear blocking ring.

39. Install the fifth gear synchronizer cone.

40. Install the fifth gear shift fork, the synchronizer assembly, the synchronizer cone and fifth gear as an assembly.

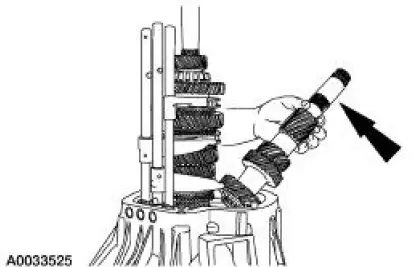

41. Install a new split pin.

- Install the pin until it is flush with the fork.

42. Install a new snap ring.

43. Install the third/fourth shift finger, then install a new split pin.

- Install the split pin until it is flush with the shift finger.

44. Install the control rail and the plastic spacer, then install the first/second shift finger. Install a new split pin.

- Install the split pin until it is flush with the shift finger.

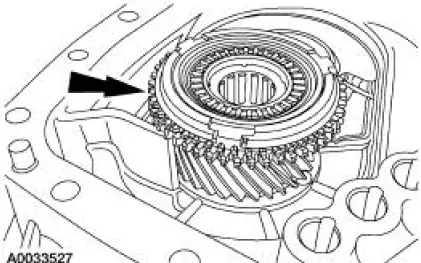

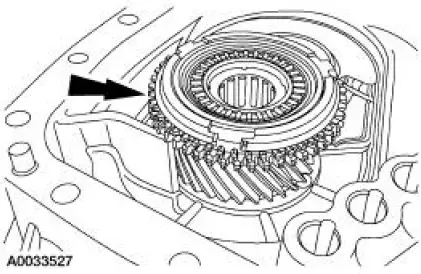

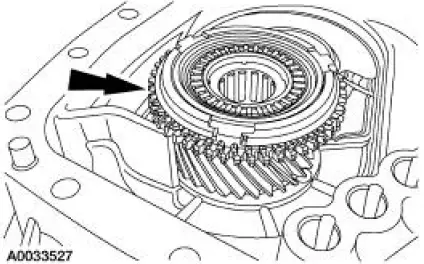

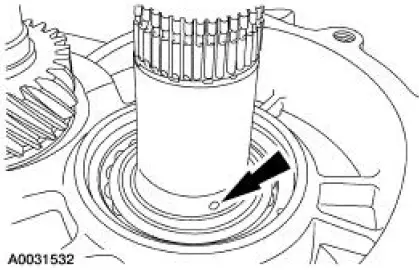

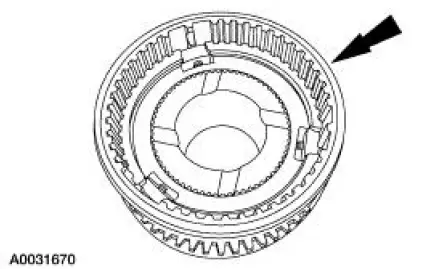

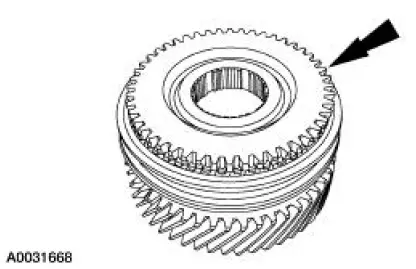

45. Install the OSS sensor tone wheel check ball.

- Use petroleum jelly to hold the check ball in place.

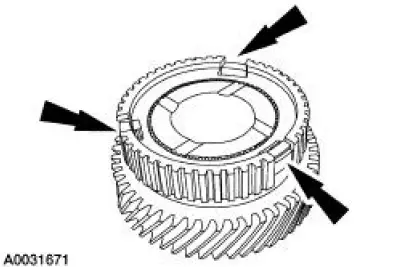

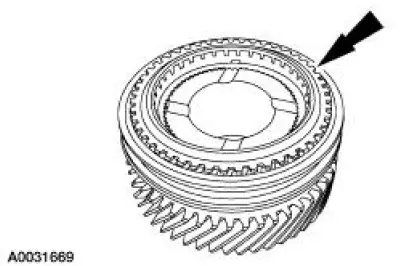

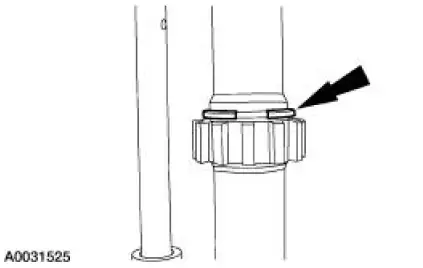

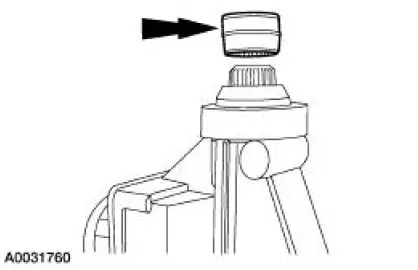

46. Place the OSS sensor tone wheel on the output shaft, aligning the slot in the OSS wheel with the check ball. Using the special tool, install the OSS sensor tone wheel.

47. Install a new OSS sensor tone wheel retaining ring.

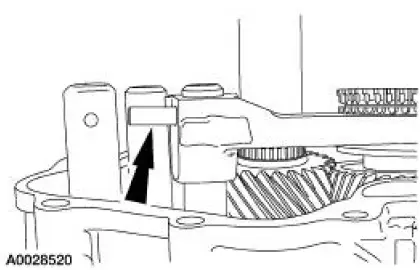

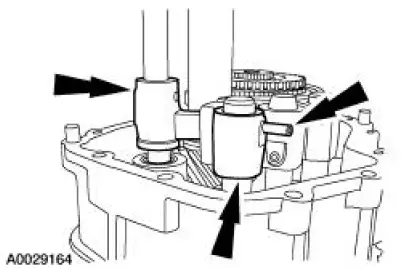

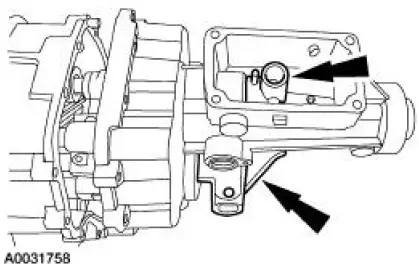

48. Install the fifth/reverse gear lockout.

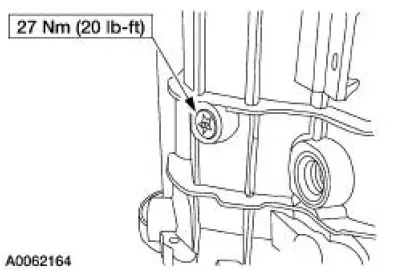

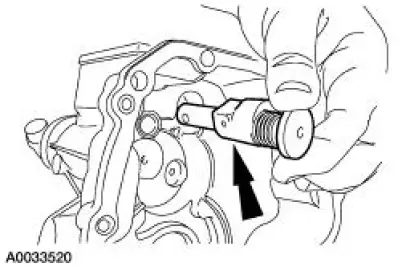

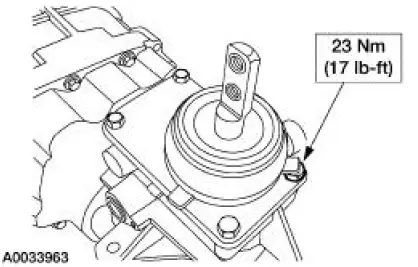

49. Install the bolt.

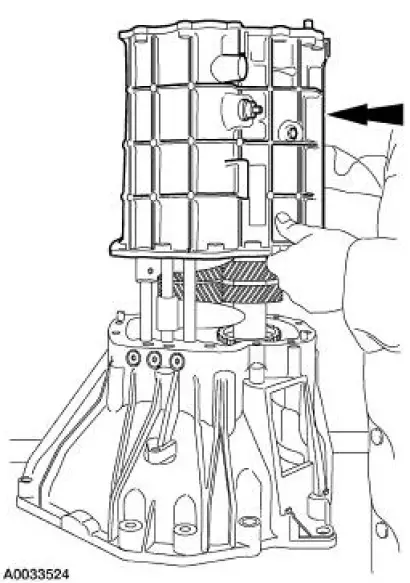

50. Clean the mating surfaces of the transmission main case and the extension housing. Apply a bead of silicone rubber to the sealing surface of the transmission case.

51. Install the extension housing and at the same time install the gear shift off-set lever.

52. Install the shift spring and bracket.

53. Install a new split pin in the gear shift off-set lever.

- The split pin should be flush in the gear shift off-set lever.

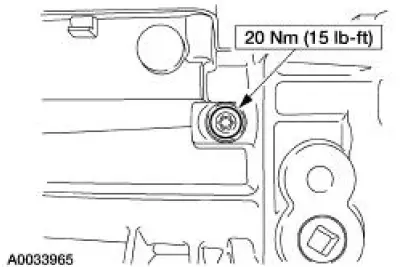

54. Seat the extension housing and tighten the bolts to specification.

- Fill the gear shift off-set lever with petroleum jelly.

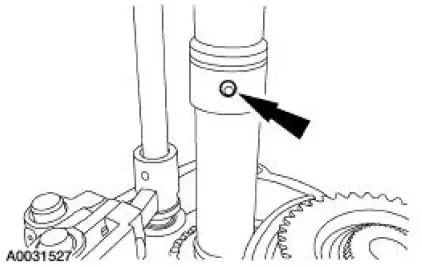

55. Using the special tool, install a new extension housing seal.

- Lubricate the seal with transmission fluid.

56. Install the shipping seal.

57. Rotate the transmission to a horizontal position.

58. Clean the mating surfaces of the shift cover opening surface and the shift cover. Apply a bead of silicone rubber to the shift cover opening surface.

59. Install the gear shift lever.

60. NOTE: Before installing the transmission, the ball stud, the clutch release lever and the input shaft guide tube must be cleaned and lubricated.

Install the clutch release hub and bearing and the clutch release lever. For additional information, refer to Section.

61. Fill the transmission with transmission fluid to the specified level.

- Transmission capacity is 3.6 liters (7.5 pints).

Gearshift Rail and Fork

Gearshift Rail and Fork

Disassembly and Assembly

1. Using a 5/32-inch drift and a hammer, remove and discard the split pin.

Slide the shift fork from

the shift rail.

2. Remove the gearshift fork inserts.

3. CAUTION: Sup ...

Other materials:

Exterior Trim and Ornamentation

Torque Specifications

Exterior Trim and Ornamentation

The exterior trim and ornamentation consists of the following

components:

body side scoop

hood scoop (if equipped)

front spoiler (Mach 1)

radiator grille

rear spoiler (if equipped)

...

Manual Transmission and Clutch (Description and Operation)

The primary function of the clutch is to couple and uncouple engine

power to the transmission upon

driver command. For additional information, refer to Section.

Clutch Disc and Clutch Pressure Plate - 3.8L

Clutch Disc and Clutch Pressure Pl ...

Transmission (Assembly)

Special Tool(s)

Dial Indicator with Bracketry

100-002 (TOOL-4201-C) or

Equivalent

Gauge, Clutch Housing

308-021 (T75L-4201-A)

Extension Housing Seal

Replacer

308-227 (T94P-7657-A)

Holding Fixture

307-0 ...