Ford Mustang (1999-2004) Service Manual: Removal

1. Raise and support the vehicle.

2. Remove the rear wheel and tire assemblies.

3. CAUTION: Remove the rear brake calipers to prevent drag during the drive pinion bearing preload adjustment.

CAUTION: Do not allow the calipers to hang from the brake hoses.

Remove the rear brake caliper and support bracket from the knuckle as an assembly. Wire the caliper and support bracket assembly out of the way.

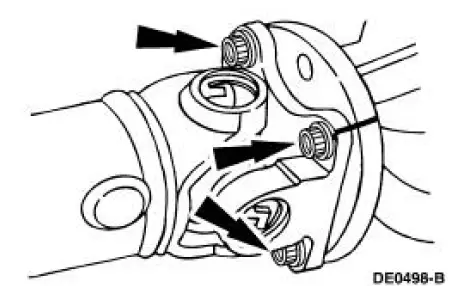

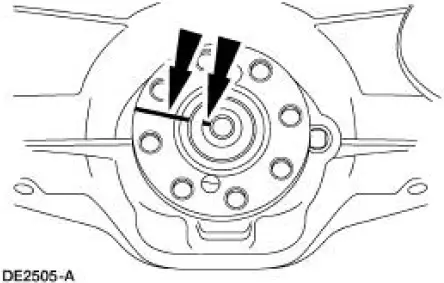

4. CAUTION: Index-mark the driveshaft flange and rear axle pinion flange (4851) to maintain initial balance during installation.

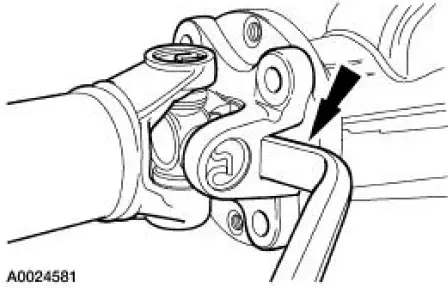

CAUTION: The driveshaft centering socket yoke fits tightly on the rear axle pinion flange pilot. Never hammer on the driveshaft (4602) or any of its components to disconnect the yoke from the flange. Pry only in the area shown, with a suitable tool, to disconnect the yoke from the flange.

Disconnect and position the driveshaft out of the way.

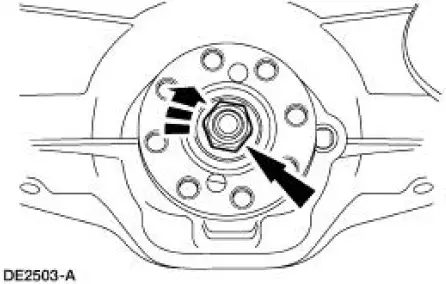

5. Install an Nm (inch/pound) torque wrench on the nut and record the torque necessary to maintain rotation of the drive pinion gear through several revolutions.

6. CAUTION: After removing the nut, discard it. Use a new nut for installation.

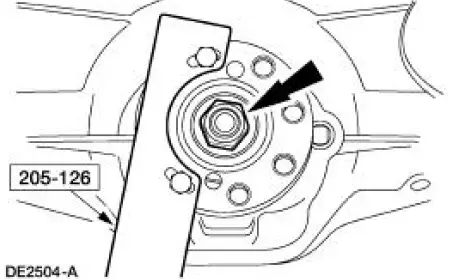

Use the special tool to hold the rear axle pinion flange while removing the nut.

7. Index-mark the rear axle pinion flange and drive pinion gear stem to maintain initial balance during installation.

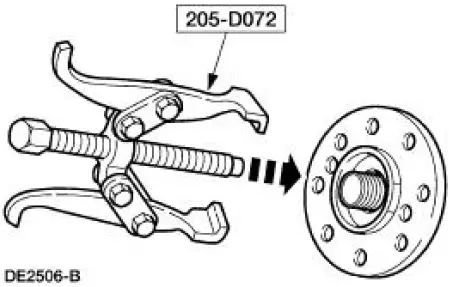

8. Using the special tool, remove the rear axle pinion flange.

Drive Pinion Flange

Drive Pinion Flange

Special Tool(s)

2-Jaw Puller

205-D072 (D97L-4221-A) or

equivalent

Holding Fixture, Drive Pinion

Flange

205-126 (T78P-4851-A)

Installer, Drive Pinion Flange

205-002 ...

Installation

Installation

1. Inspect the rear axle pinion flange seal journal for rust, nicks, and

scratches prior to installing

the flange. Polish the seal journal with fine crocus cloth, if necessary.

2. Lubricate the rear ...

Other materials:

Installation

1. NOTE: Inspect the spring insulators for wear or damage. Install new

spring insulators if

necessary.

Make sure the spring insulators are correctly installed on the springs.

2. Install the springs.

1. Position the springs.

2. Raise the subframe using ...

Axle

Special Tool(s)

2-Jaw Puller

205-D072 (D97L-4221-A) or

equivalent

Adapter for 205-S127

205-105 (T76P-4020-A3)

Bearing Preload Tool

205-395 (T93P-4220-A)

Plate, Bearing/Oil Seal

205-090 (T75L-1165-B)

Gauge, ...

Air Conditioning Line (Peanut) Fitting

Disconnect

1. CAUTION: Support the female fitting with a wrench to prevent the

tubes from

twisting.

Remove the nut from the peanut fitting.

2. Pull the peanut fitting apart.

3. CAUTION: Do not use metal tools to remove the O-ring seal. They can

cause axi ...