Ford Mustang (1999-2004) Service Manual: Assembly

1. Carry out the following before reassembling:

- Inspect the gears for broken or cracked teeth. Check for unusual wear patterns.

- Inspect the thrust washers for face wear, cracks, scoring and for signs of heat damage.

- Inspect the bearings, bearing cups and the synchronizers for wear or damage.

- Inspect the output shaft for scoring or worn or damaged splines. Install new components as necessary.

2. Lubricate all components with the recommended transmission fluid when reassembling.

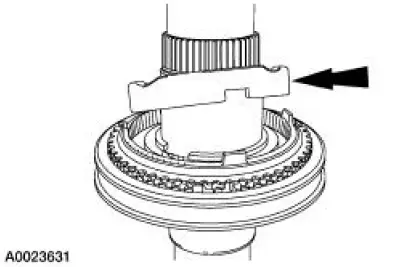

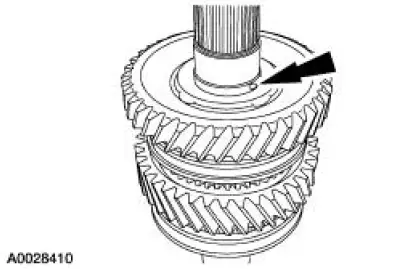

3. NOTE: Position the output shaft with the output end facing upward.

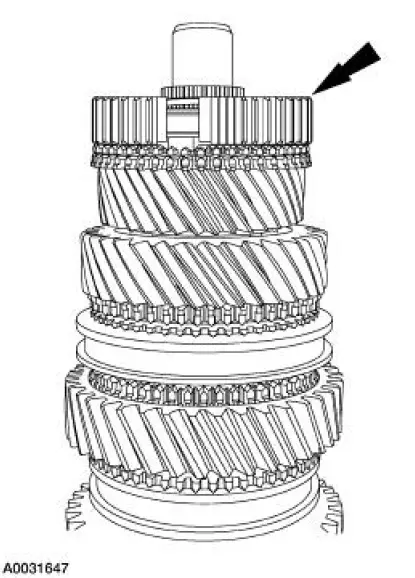

NOTE: Install the synchronizer assembly with the deeper center flange of the synchronizer hub facing toward the rear of the output shaft.

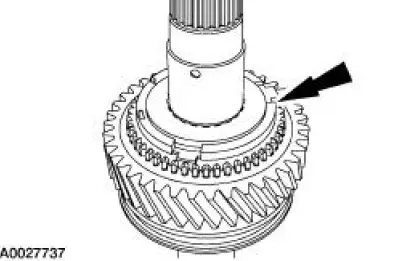

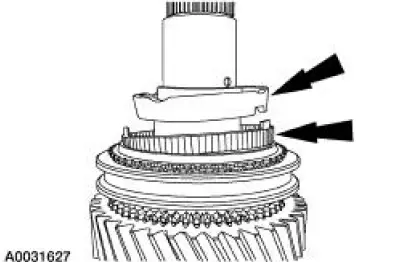

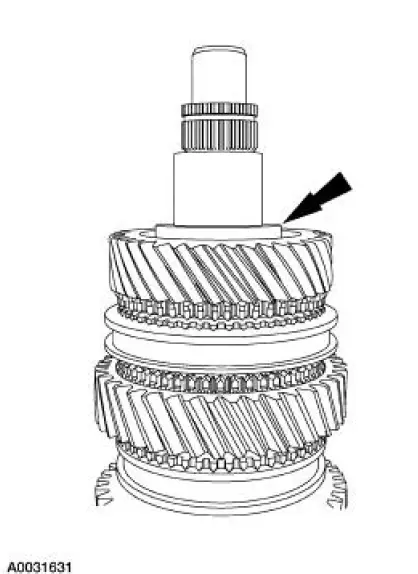

Install the first/second synchronizer assembly on the output shaft, then install a new retaining ring.

- It may be necessary to press the hub into position on the shaft.

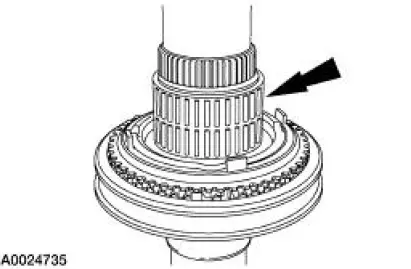

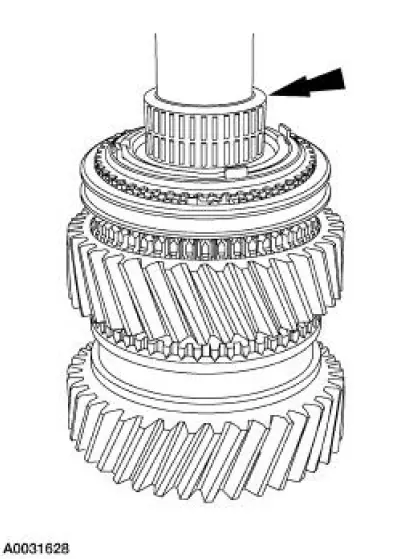

4. Install the first gear synchronizer blocking ring.

- Align the blocking ring tabs with the synchronizer assembly.

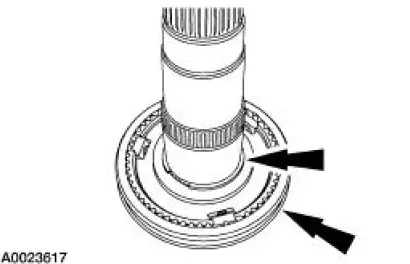

5. Install the outer first gear synchronizer cone.

6. Install the inner first gear synchronizer cone. Rotate the inner cone till it is seated.

7. Install the first gear needle bearing.

- Apply petroleum jelly to the bearing.

8. Install first gear.

- Rotate the gear to align the gear slots with the inner cone tabs.

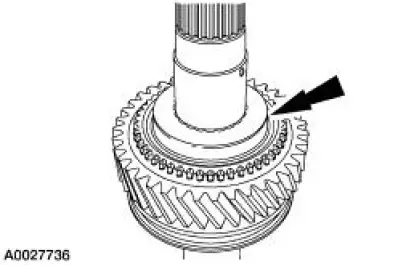

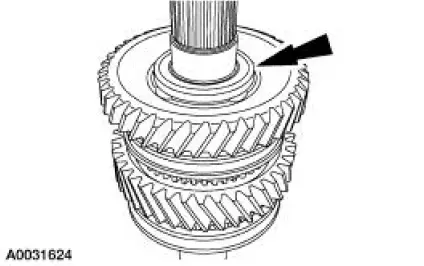

9. Install the reverse synchronizer cone.

10. Install the reverse gear blocking ring.

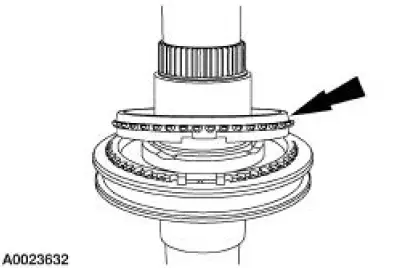

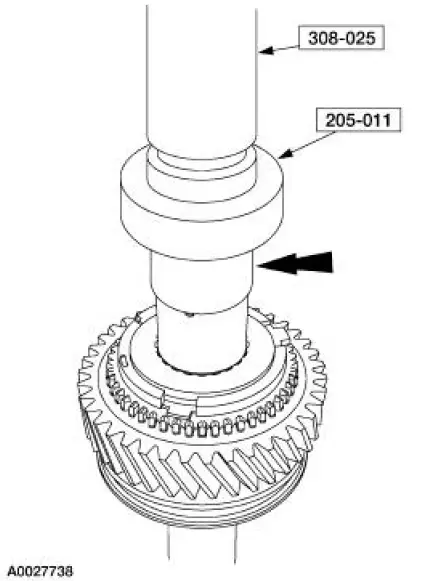

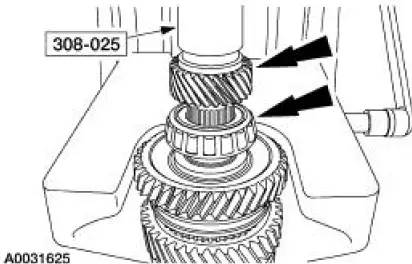

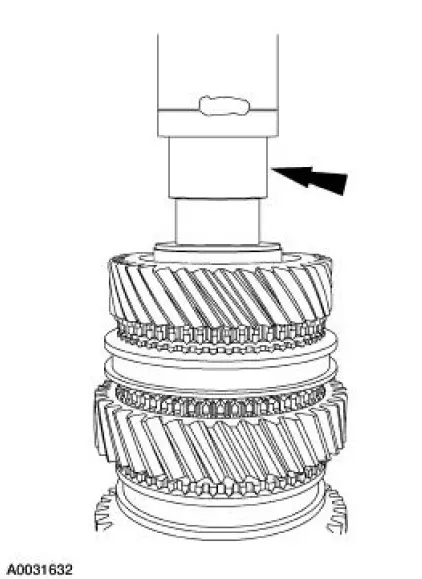

11. Using the special tools, install the reverse gear bearing spacer.

12. Install reverse gear needle bearing.

- Apply petroleum jelly to the bearing.

13. Install reverse gear.

- Rotate the gear to align the gear slots with the inner cone tabs.

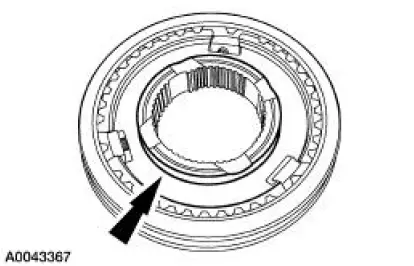

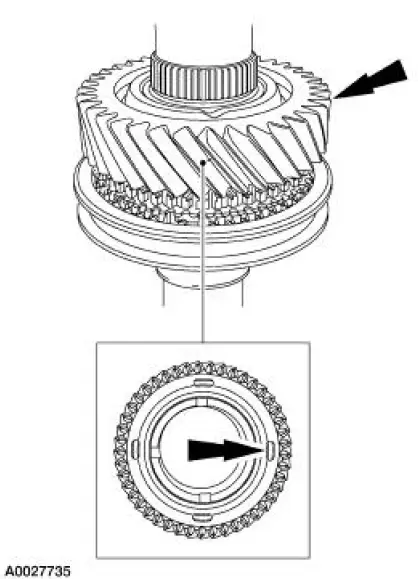

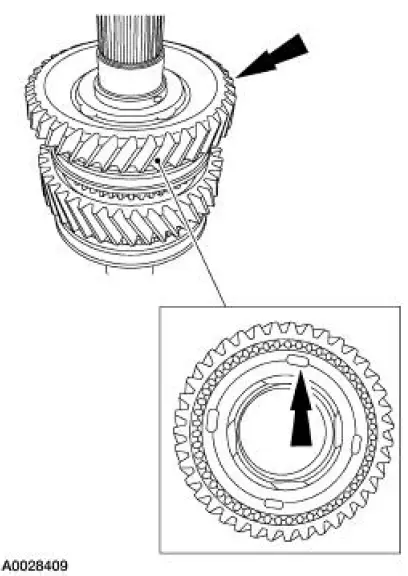

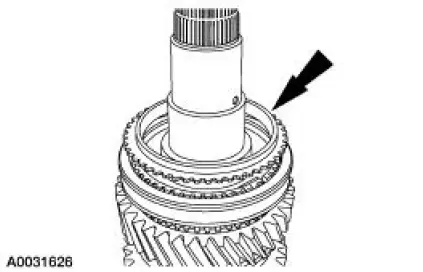

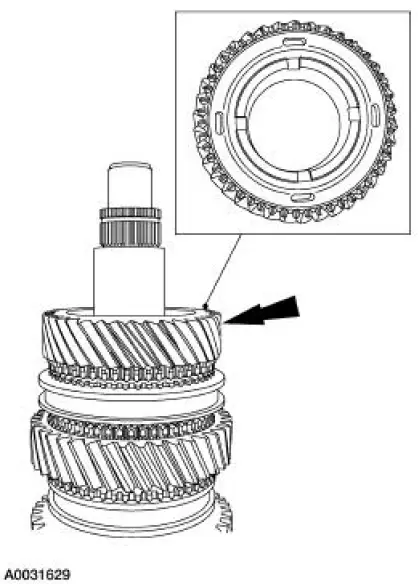

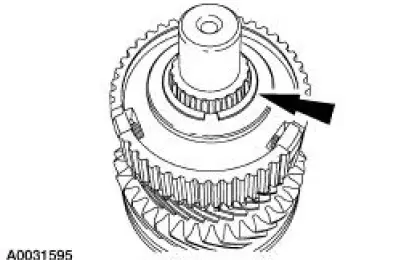

14. Install the check ball.

- Use petroleum jelly to hold the check ball in place.

15. Install the thrust washer. Be sure to align the slot in the washer with the check ball.

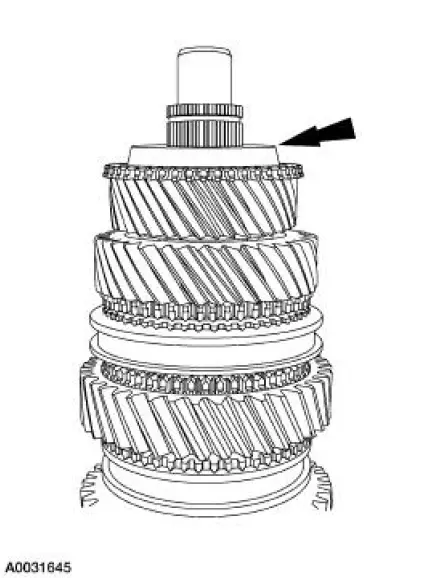

16. Install a new rear output shaft bearing, then fifth gear. Using the special tool, press both the bearing and gear into place.

17. Reposition the output shaft with the input end facing upward.

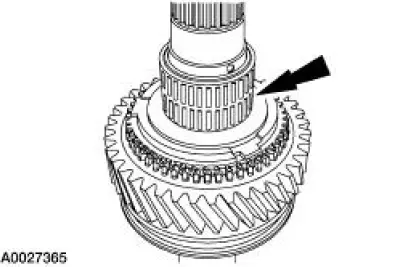

18. Install the second gear synchronizer blocking ring. Rotate the blocking ring until seated.

19. Install the second gear synchronizer outer cone and the second gear synchronizer inner cone.

20. Install the second gear bearing.

- Apply petroleum jelly to the bearing.

21. Install second gear.

- Rotate the gear to align the gear slots with the inner cone tabs.

22. Install the check ball.

- Use petroleum jelly to hold the check ball in place.

23. Install the thrust washer. Be sure to align the slot in the washer with the check ball.

24. Press the bearing spacer onto the output shaft.

25. Install the third gear bearing.

- Apply petroleum jelly to the bearing.

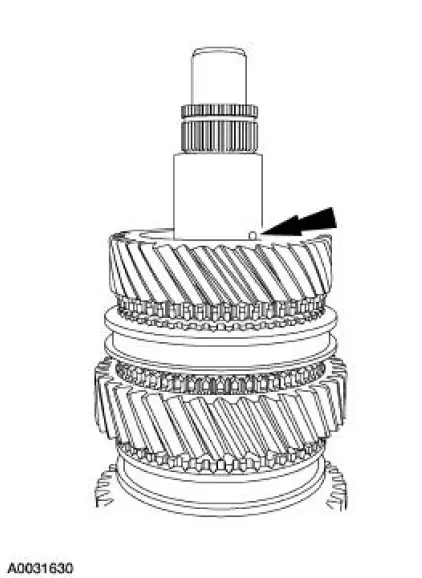

26. Install third gear.

27. Install the third gear synchronizer blocking ring.

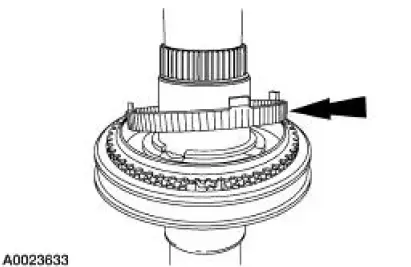

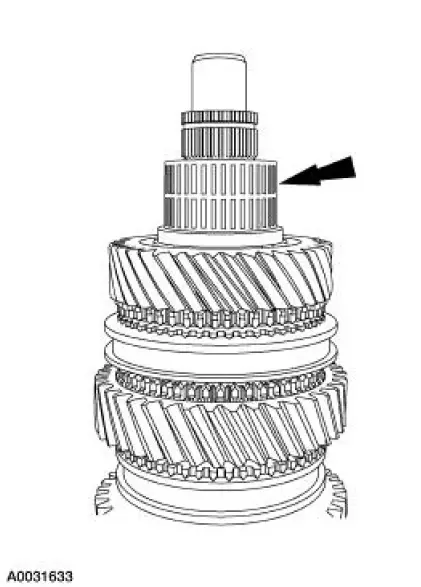

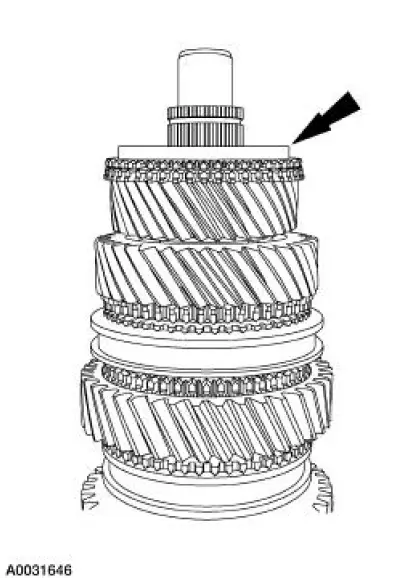

28. Install the third/fourth gear synchronizer body.

- Install the synchronizer body with the raised center facing downward.

- Rotate the blocking ring until seated.

29. Install a new retaining ring.

Disassembly

Disassembly

1. Remove the retaining ring above fifth gear.

2. CAUTION: Hand tighten the special tool to prevent gear damage.

CAUTION: Support the output shaft while using the press to prevent

damage to the

sha ...

Countershaft Bearing

Countershaft Bearing

Special Tool(s)

Remover, Drive Pinion Bearing

Cone

205-D002 (D79L-4621-A) or

equivalent

Installer, Drive Pinion Bearing

Cone

205-011 (T57L-4621-B)

Disassembly and A ...

Other materials:

Heated windows and mirrors (if equipped)

Heated Rear Window

Note: The vehicle must be running to use this feature.

Press the control to clear the rear window of thin ice and fog. Press the

control again within 15 minutes to switch it off. It turns off automatically

after approximately 15 minutes, or ...

Switch - Window Regulator Control

Removal

1. CAUTION: Use a shop towel or similar material between the

tool and the door trim

panel or damage to the door trim panel may occur.

Position the window regulator switch plate aside.

1. Pull at the service notch.

2. Lift to release ...

Unique Calibration

The Emissions/CAFE/CO2 Compliance Department is responsible for assigning

these calibration

numbers. Unique calibration identifications are assigned to cover similar

vehicles to differentiate tires,

drive configurations, final drive ratios and other calibrat ...