Ford Mustang (1999-2004) Service Manual: Assembly

All steering gears

1. Install the steering gear in the special tools.

Steering gears equipped with travel restrictors

2. Install the travel restrictors.

- Install new travel restrictors as necessary.

All steering gears

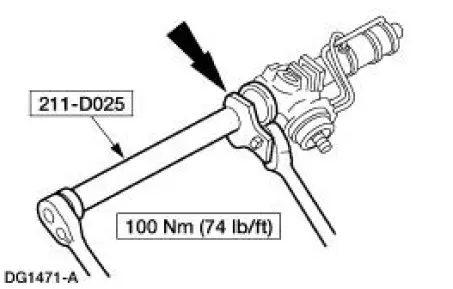

3. CAUTION: Place the steering gear at the center position. Use a crowfoot on the flat of the rack gear to resist rotation and prevent damage to the steering gear during removal and installation of the front wheel spindle tie-rods.

Place the steering gear at the center position. Install a crowfoot on the flat of the steering gear.

Using the special tool install the front wheel spindle tie-rods.

4. Thoroughly clean the steering gear of any foreign material.

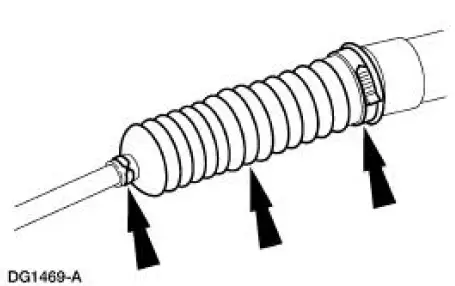

5. CAUTION: Use care not to damage the front suspension steering ball stud dust seals. If the front suspension steering ball stud dust seals are damaged, this will allow contamination into the steering gear and cause leakage.

Install the front suspension steering ball stud dust seals and clamps.

- Position the front suspension steering ball stud seals and steering gear rack tubes as shown.

- Install new front suspension steering ball stud dust seals and clamps as necessary.

- To prevent the front suspension steering ball stud dust seals from twisting during toe adjustment, apply grease to the groove in the front wheel spindle tie-rods and uniformly to the inner-diameter of the front suspension steering ball stud dust seals.

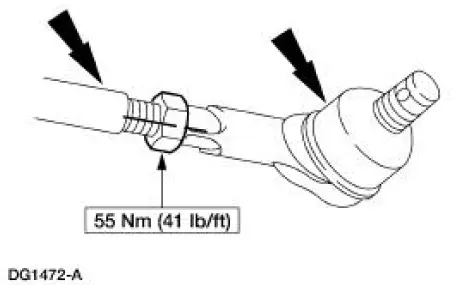

6. Install the nut and the tie-rods ends. Align the marks.

- Apply silicone dielectric compound to the front wheel spindle tie-rod threads.

7. Remove the steering gear from the special tools.

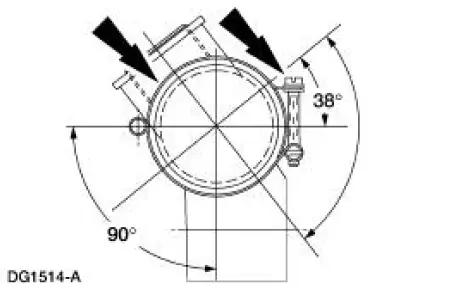

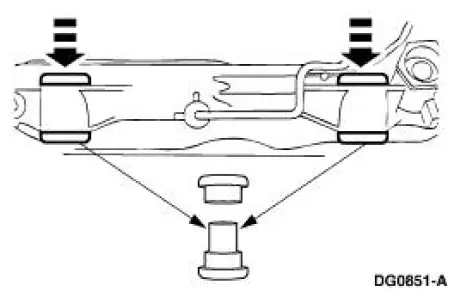

8. Install the steering gear mounting bracket housing insulators.

- Install new steering gear mounting bracket housing insulators as necessary.

- The large end of the metal sleeve must be positioned downward.

- Check that the mounting surfaces are clean and free of foreign material.

Disassembly

Disassembly

NOTE: The steering gear is serviceable as either a long or short rack

assembly. This procedure covers

the removal and installation of the components not supplied with a short rack

assembly. On short ...

Steering Column

Steering Column

General Specifications

Torque Specifications

...

Other materials:

Forward Clutch Cylinder

Special Tool(s)

Dial Indicator Gauge with

Holding Fixture

100-002 (TOOL-4201-C) or

equivalent

Compressor, Clutch Spring

307-096 (T81P-70235-A)

Protector, Transmission

Forward Clutch Outer Fluid

Seal

307-423

M ...

Installation

1. Overlay the new rear window glass assembly over the old rear

window glass assembly and

transpose the markings with a grease pencil.

2. Center the V-notch on the new rear window glass assembly to the

center mark on the top of the

number four bow ...

Inspection and Verification

1. Verify the customer concern is with the evaporative emission (EVAP)

system.

2. Visually inspect for the following obvious signs of mechanical damage.

Visual Inspection Chart

Mechanical

Fuel filler cap

EVAP test port

...