Ford Mustang (1999-2004) Service Manual: Axle Housing

Removal and Installation

1. CAUTION: The vehicle must be on level ground and at curb height.

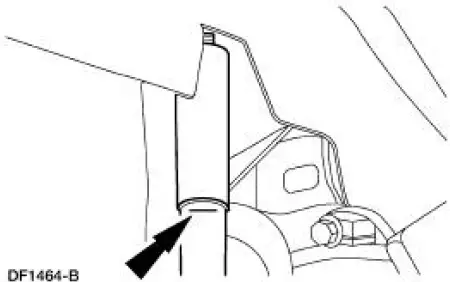

Mark the rear shock absorbers relative to their protective sleeve.

- During installation, raise the suspension to this reference mark before tightening the suspension fasteners.

2. Raise and support the vehicle.

3. Remove the rear wheel and tire assemblies.

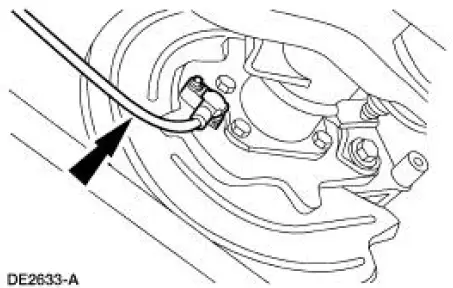

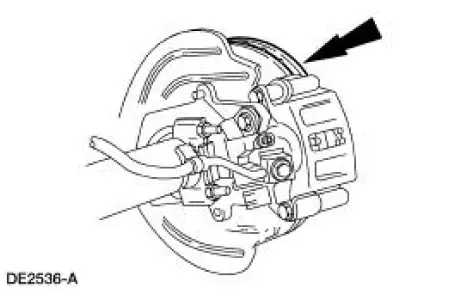

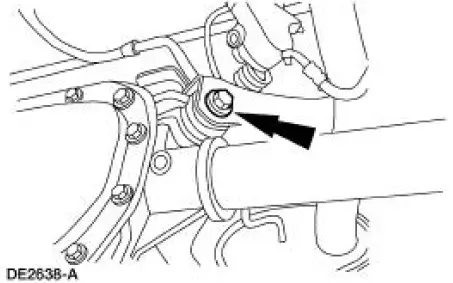

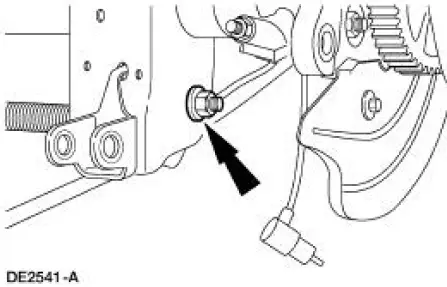

4. NOTE: If necessary, use Rust Penetrant and Inhibitor F2AZ-19A501-A meeting Ford specification ESR-M99C56-A to loosen the sensor for removal.

Remove the rear anti-lock brake sensors from the rear disc brake adapters

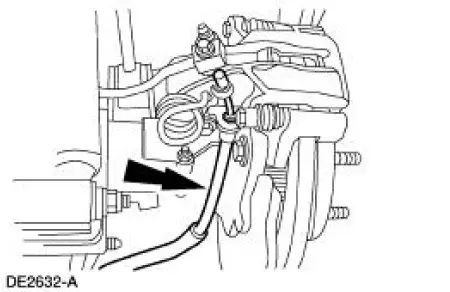

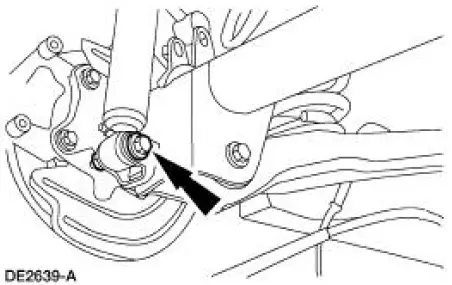

5. Disconnect the parking brake cables and conduits from the rear disc brake calipers.

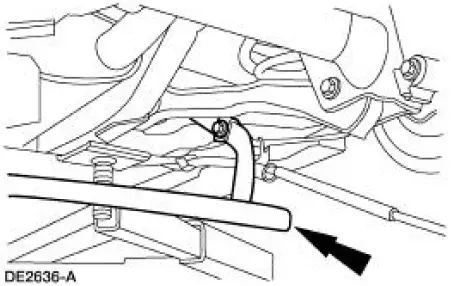

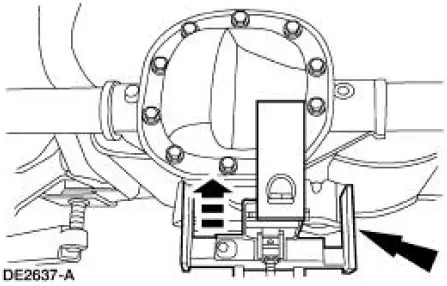

6. Disconnect the rear axle drive line vibration damper from the axle.

7. CAUTION: Index-mark the brake discs and the wheel studs prior to brake disc removal.

CAUTION: Do not allow the calipers to hang from the brake hoses.

Remove the rear brake discs.

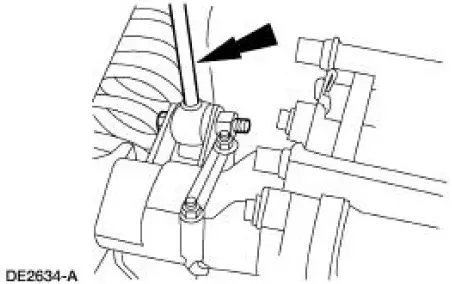

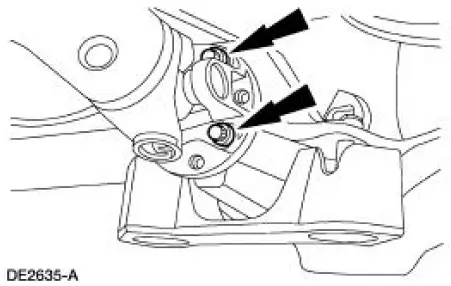

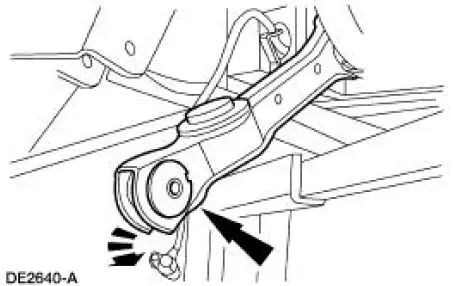

8. CAUTION: Index-mark the driveshaft flange and pinion flange (4851) to maintain initial balance during installation.

CAUTION: The driveshaft centering socket yoke fits tightly on the pinion flange pilot. Never hammer on the driveshaft or any of its components to disconnect the yoke from the flange. Pry only in the area shown, with a suitable tool, to disconnect the yoke from the flange.

Disconnect and position the driveshaft out of the way.

9. Remove the stabilizer bar.

10. Position a suitable transmission jack under the differential housing (4010) for support and strap it securely in place.

11. Remove and discard the nuts and bolts retaining the upper suspension arm and bushings to the differential housing.

12. Remove and discard the nuts and bolts retaining the shock absorbers to the axle.

13. Lower the differential housing to unload the rear springs.

14. Remove the rear springs.

15. Remove and discard the nuts and bolts retaining the lower suspension arm and bushings to the axle.

16. Disconnect the lower suspension arm and bushings from the axle.

17. Remove the axle from the vehicle.

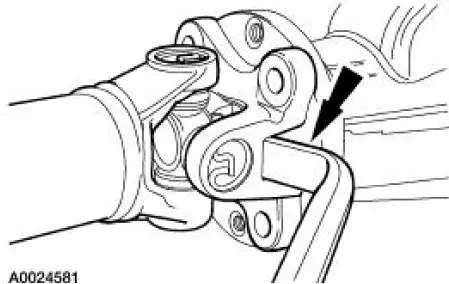

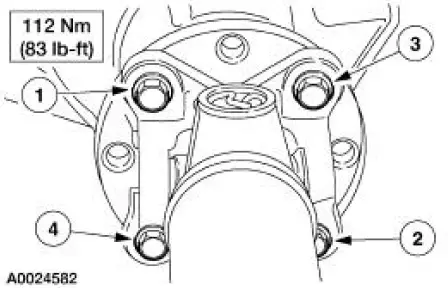

18. CAUTION: Align the index marks on the driveshaft centering socket yoke and the pinion flange.

CAUTION: Install the driveshaft with new bolts. If new bolts are not available, apply Threadlock and Sealer EOAZ-19554-AA or equivalent meeting Ford specification WSKM2G351- A5 to the threads of the original bolts.

CAUTION: The driveshaft centering socket yoke fits tightly on the pinion flange pilot. To make sure that the yoke seats squarely on the flange, tighten the bolts evenly in a cross pattern as shown.

CAUTION: Raise the suspension to the reference marks on the rear shock absorbers before tightening the suspension fasteners.

NOTE: Apply High Temperature Nickel Anti-Sieze Lubricant F6AZ-9L494-AA meeting Ford specification ESE-M124A-A to the rear anti-lock brake sensor body where it will make contact when installed.

Follow the removal procedure in reverse order.

- Refer to Section for rear suspension fastener tightening specifications.

- Refer to Section for wheel nut tightening specification.

Installation

Installation

All axles

1. Position the ring gear and the differential case. Align the bolt holes by

starting two bolts through

the holes in the differential case and the ring gear. Press the ring gear on the

dif ...

Differential Case and Ring Gear - Conventional

Differential Case and Ring Gear - Conventional

Special Tool(s)

2-Jaw Puller

205-D072 (D97L-4221-A) or

equivalent

Installer, Differential Side

Bearing

205-010 (T57L-4221-A2)

Step Plate

205-D061 (D83T-4205-C2) or

...

Other materials:

Fog Lamps

Refer to Wiring Diagrams Cell 86 , Fog Lamps for schematic and connector

information.

Special Tool(s)

73 III Automotive Meter or

equivalent

105-R0057

Principles of Operation

The fog lamps will only illuminate when the low beam or parking l ...

Key Release Button

Removal

1. Disconnect the battery ground cable.

2. Remove the ignition switch lock cylinder.

1. Insert the ignition key into the ignition switch lock cylinder and

turn to RUN position.

2. Push the ignition switch lock cylinder release tab with a p ...

Using voice recognition

This system helps you control many features using voice commands.

This allows you to keep your hands on the wheel and focus on what is in

front of you.

Initiating a Voice Session

Push the voice icon; a tone sounds and Listening appears in the

display. Say an ...