Ford Mustang (1999-2004) Service Manual: Cleaning

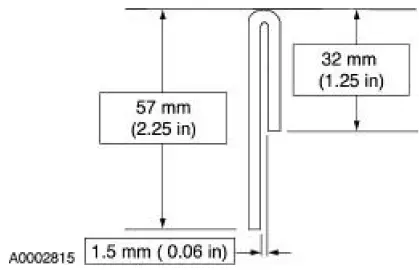

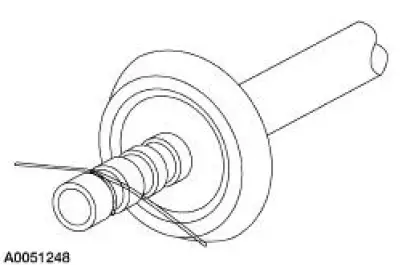

1. Fabricate a cleaning tool from a 1/8 inch diameter brazing rod.

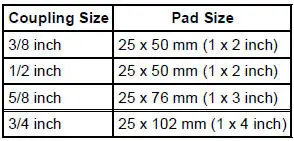

2. Cut an abrasive pad from maroon colored 3M Scotch Brite with the dimensions corresponding to the coupling size.

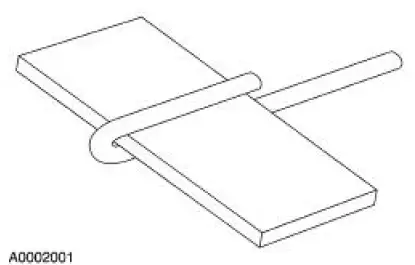

3. Assemble the pad to the tool.

4. Coat the abrasive pad with PAG Refrigerant Compressor Oil (R-134a Systems) or equivalent.

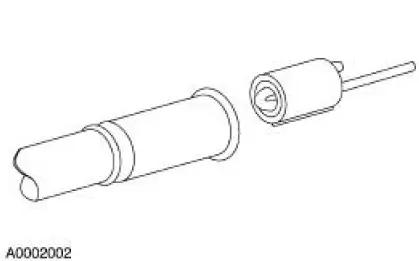

5. Roll the pad on the tool and install it in a variable speed drill motor.

6. CAUTION: Maintain low speed drill rotation when inserting or removing the cleaning tool to prevent axial scratches which may cause future leaks.

Polish for one minute at moderate speed (less than 1,500 rpm) or until the surface is clean and free of scratches or foreign material.

7. Clean the fitting with a lint-free cloth.

8. Inspect the surface for grooves or scratches. If grooves and scratches are still present, install a new component.

9. Clean the O-ring seal grooves with a 300 mm (12 inch) length of natural fiber string.

- Loop the string around the grooves and pull the string back and forth.

10. Remove any foreign material from the grooves with a lint-free cloth.

Disconnect

Disconnect

1. Remove the A/C tube lock coupling clip (19E746), if equipped.

2. Fit the special tool to the spring lock coupling.

3. Push the tool into the cage opening to release the female fitting from the ...

Connect

Connect

1. Install the A/C tube lock coupling spring.

2. Lubricate the inside of the coupling with PAG Refrigerant Compressor Oil

(R-134a Systems) or

equivalent.

3. CAUTION: Use only the new O-ring seals ...

Other materials:

Principles of operation

MyKey allows you to program keys with restricted driving modes to

promote good driving habits. You can use all but one of the keys

programmed to your vehicle with these restricted modes.

Any keys that have not been programmed are referred to as

administrator ...

Engine (Removal)

Special Tool(s)

Special Tool(s)

Support Bracket, Engine

303-639

Spreader Bar

303-D089 (D93P-6001-A3)

Lifting Bracket Set, Engine

303-D074 (D91P-6001-A)

Removal

1. Remove the hood.

2. Remove the battery. For additi ...

Pinpoint Tests - OSC Equipped Vehicles

Special Tool(s)

Breakout Box, EEC-V Control

System

418-049 (T94L-50-EEC-V) or

equivalent

MLP-TR Cable

418-F107 (007-00111) or

equivalent

Worldwide Diagnostic System

(WDS)

418-F224

New Generation STAR (NGS)

T ...