Ford Mustang (1999-2004) Service Manual: Communication Circuit Wiring Repair

Special Tool(s)

|

Heat Gun 107-R0300 or equivalent |

1. Disconnect the battery ground cable. For additional information, refer to Section.

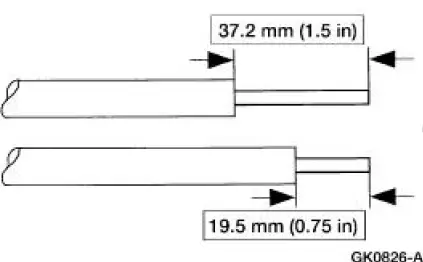

2. Strip the wires.

3. NOTE: Use rosin core mildly activated (RMA) solder, not acid core solder.

Solder the wires.

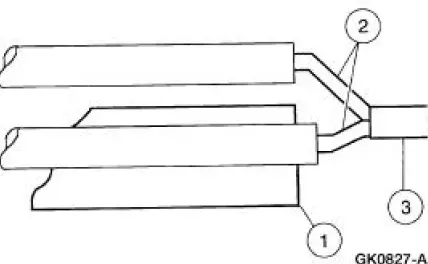

1. Install the heat shrink tube.

2. Twist the wires together.

3. Solder the wires together.

4. NOTE: Wait for the solder to cool before moving the wires.

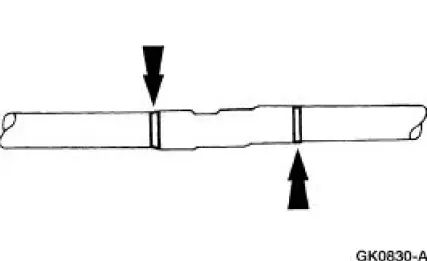

Bend the wires back in a straight line.

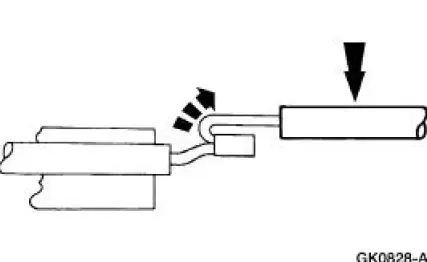

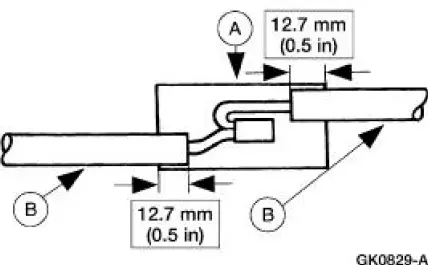

5. Position the (A) heat shrink tube over the (B) wire repair.

- Overlap the heat shrink tube on both wires.

6. Use the heat gun to heat the repaired area until adhesive flows out both ends of the heat shrink tube.

7. Reconnect the battery ground cable.

Pinpoint Tests

Pinpoint Tests

CAUTION: Be careful when probing the CJB, battery junction box (BJB)

or any

connectors. Damage will result to the connector receptacle if the probe or

terminal being used

is too large.

CAUTION ...

Module Configuration

Module Configuration

Module Configuration (Diagnosis and Testing)

Special Tool(s)

Worldwide Diagnostic System

(WDS)

418-F224

New Generation STAR (NGS)

Tester

418-F052 or equivalent

diagnostic tool ...

Other materials:

Functionality

With the ignition switch in the RUN position, voltage is applied

through the warning indicator I circuit

904 (LG/RD) to the voltage regulator. This turns the regulator on,

allowing current to flow from battery

sense A circuit 36 (YE/WH) to the genera ...

Parking Brake Control

Removal

1. CAUTION: If any component in the parking brake system requires

repair or if the

rear axle housing (4010) is removed, the cable tension must be released.

Place the parking brake control (2780) in the released position.

2. Remove the console.

3. ...

Axle Housing

Removal and Installation

1. CAUTION: The vehicle must be on level ground and at curb height.

Mark the rear shock absorbers relative to their protective sleeve.

During installation, raise the suspension to this reference mark

before tightening the

s ...