Ford Mustang (1999-2004) Service Manual: Disassembly

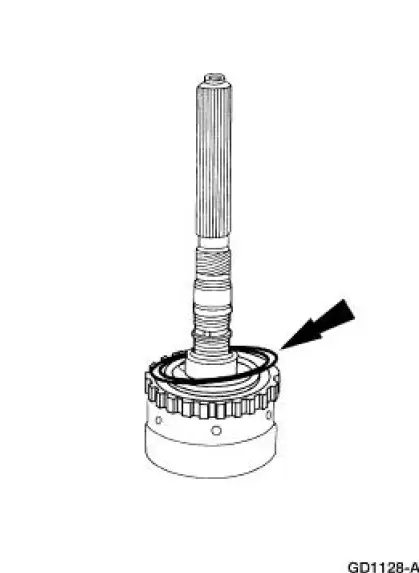

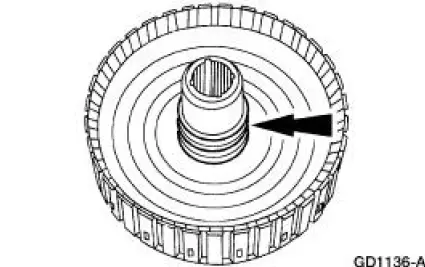

1. NOTE: The index mark on the output shaft must be aligned with the index mark on the output shaft ring gear during the assembly procedure.

Remove the ring gear snap ring.

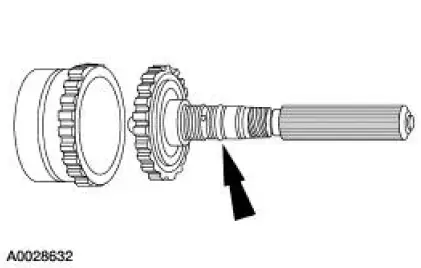

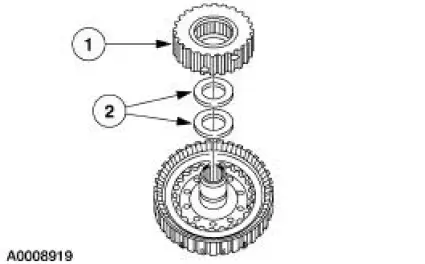

2. Separate the ring gear and output shaft.

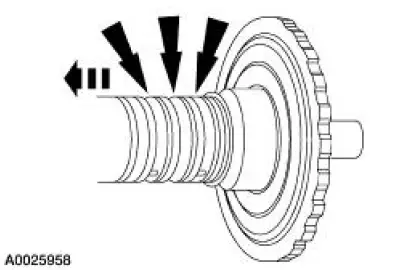

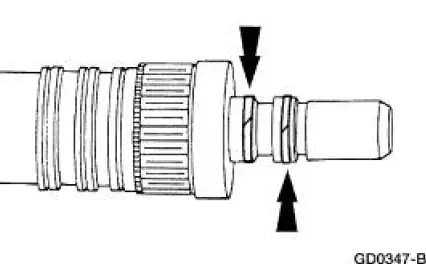

3. Remove the three output shaft seal rings.

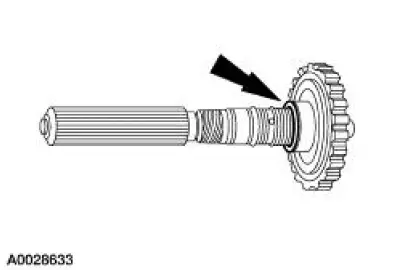

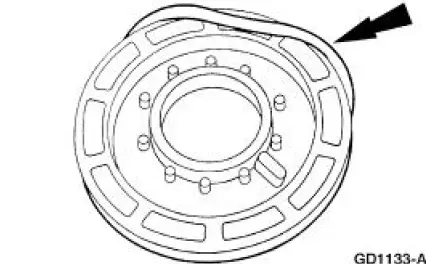

4. Remove the output shaft hub snap ring and the output shaft hub.

5. Remove the two direct clutch seal rings.

6. Remove the No. 7 direct clutch inner bearing support.

1. Remove the direct clutch hub.

2. Remove the No. 7 direct clutch inner bearing support.

7. Inspect the clutch cylinder thrust surfaces, piston bore and clutch plate serrations for scores or burrs. Minor scores or burrs may be removed with a crocus cloth. Install a new clutch cylinder if badly scored or damaged.

8. Check the fluid passage in the clutch cylinder for obstructions. Clean out all fluid passages.

Inspect the clutch piston for scores and install new if necessary. Inspect the check balls for freedom of movement and correct seating.

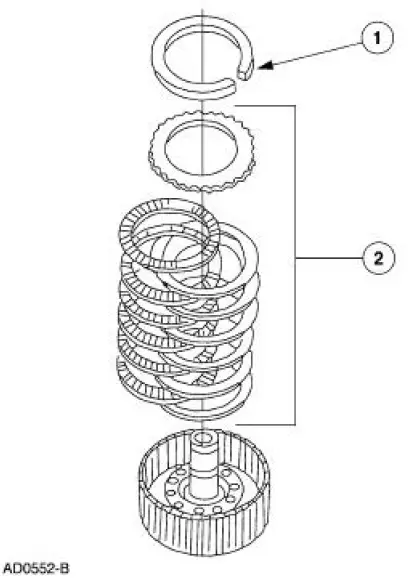

9. Check clutch release spring for distortion and cracks. Install a new spring (including wave spring) if distorted or cracked.

10. Inspect composition clutch plates, steel clutch plates and clutch pressure plate for worn or scored bearing surfaces. Install new parts if they are deeply scored or burred.

11. Check the clutch plates for flatness and fit on the clutch hub serrations. Discard any plate that does not slide freely on the serrations or that is not flat.

12. Check the clutch hub thrust surfaces for scores and clutch hub splines for wear.

13. Remove the direct clutch pack.

1. Remove the selective retaining ring.

2. Remove the direct clutch pack.

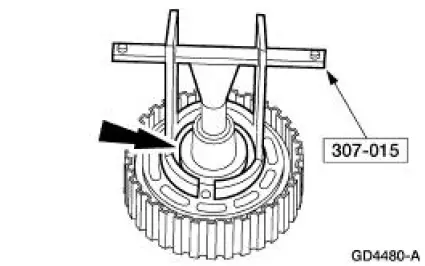

14. Using the special tool, compress the piston return spring and remove the snap ring.

15. WARNING: Wear safety glasses when using compressed air.

NOTE: If necessary, use regulated compressed air 207 kPa (30 psi) max pressure to remove the clutch piston.

Remove the support and spring assembly and piston.

16. Remove the inner piston seal.

17. Remove the outer piston seal.

Output Shaft and Direct Clutch Cylinder

Output Shaft and Direct Clutch Cylinder

Special Tool(s)

Compressor, Clutch Spring

307-015 (T65L-77515-A)

Protector, Piston Seal

307-080 (T80L-77234-A)

Protector, Transmission Direct

Clutch Outer Flui ...

Assembly

Assembly

1. NOTE: Lubricate direct clutch piston inner seal and seal protector

with petroleum jelly.

Using the special tool, install the inner piston seal.

Install the seal with sealing lip facing down.

...

Other materials:

Lumbar Control Switch

Removal and Installation

All vehicles

1. Remove the front seat. For additional information, refer to Seat-Front

Power in this section.

Vehicles with standard power lumbar

2. Pull to remove the lumbar control switch (14C715).

3. Disconnect the power lum ...

Using the boot

Installing the Boot

WARNING: Always secure the retaining clips and boot straps on

the vehicle or the boot may come loose while driving.

Note: Be sure the boot is secure on the vehicle before driving.

Improper

installation can result in loss or damage of the b ...

Fuel consumption

Filling the Tank

The advertised capacity is the indicated capacity and the empty reserve

combined. Indicated capacity is the difference in the amount of fuel in a

full tank and a tank when the fuel gauge indicates empty. Empty reserve

is the amount of fuel in ...