Ford Mustang (1999-2004) Service Manual: Evaporative Emission Canister Purge Valve

Removal and Installation

1. WARNING: The evaporative emission system contains fuel vapor and condensed fuel vapor. Although not in large quantities, it still presents the danger of explosion or fire. Disconnect the battery ground cable from the battery to minimize the possibility of an electrical spark occurring, possibly causing a fire or explosion if fuel vapor or fuel liquid is present in the area. Failure to follow these instructions may result in personal injury.

Disconnect the battery ground cable. For additional information, refer to Section.

2. Raise and support the vehicle. For additional information, refer to Section.

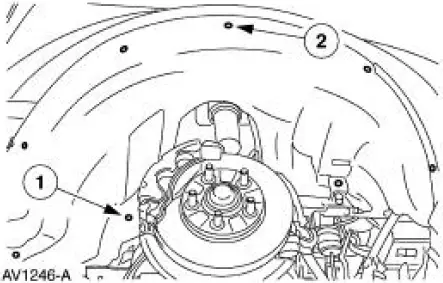

3. Remove the RH front wheel. For additional information, refer to Section.

4. Remove the right front splash shield.

1. Remove the three screws.

2. Remove the five pin-type retainers.

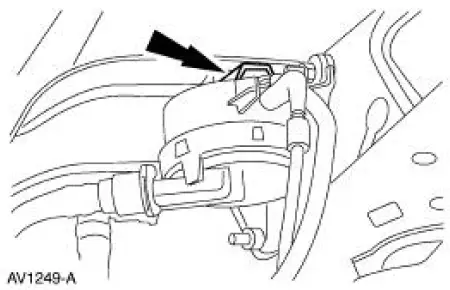

5. Disconnect the connector.

6. Disconnect the main emission vacuum control connector.

7. WARNING: Do not smoke or carry lighted tobacco or open flame of any type when working on or around any fuel-related component. Highly flammable mixtures are always present and may be ignited. Failure to follow these instructions may result in personal injury.

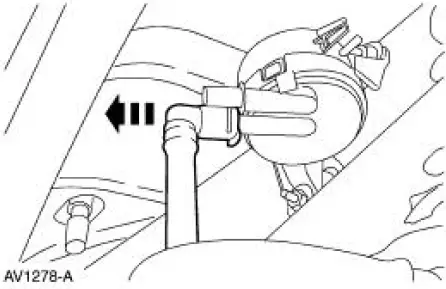

Disconnect the evaporative emission (EVAP) canister purge outlet tube.

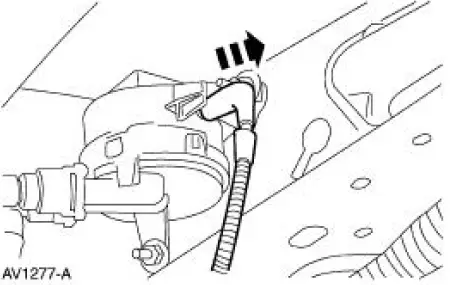

8. Disconnect the EVAP return tube.

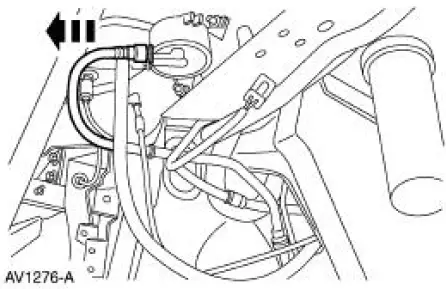

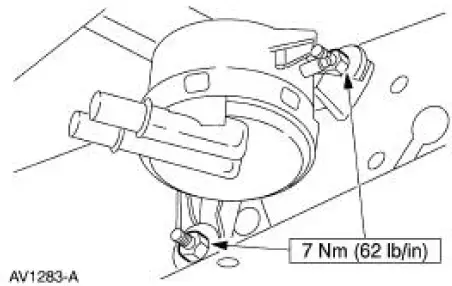

9. Remove the nuts and the EVAP canister purge valve.

10. To install, reverse the removal procedure.

- Leak test the system. For additional information, refer to Evaporative Emission System Leak Test in this section.

- Carry out the evaporative emission repair verification drive cycle. For additional information, refer to Evaporative Emission Repair Verification Drive Cycle in this section.

Fuel Vapor Vent Valve

Removal and Installation

1. NOTE: The fuel vapor vent valve is repaired along with the fuel vapor control valve and the inline fuel tank pressure sensor as a fuel vapor control valve tube assembly.

For removal and installation of the fuel vapor vent valve, refer to Fuel Vapor Control Tube Assembly Valve in this section.

Evaporative Emission Canister

Evaporative Emission Canister

Removal and Installation

1. WARNING: The evaporative emission system contains fuel vapor

and condensed

fuel vapor. Although not in large quantities, it still presents the

danger of explosion ...

Fuel Vapor Control Tube Assembly Valve

Fuel Vapor Control Tube Assembly Valve

Removal and Installation

1. Remove the fuel tank. For additional information, refer to

Section.

2. Remove the retainers.

3. NOTE: The fuel vapor vent valve, fuel vapor control valve and the ...

Other materials:

Transmission Draining and Filling

Material

Item

Specification

DEXRON III (ATF)

Transmission Fluid

XT-2-QDX

DEXRON III

1. Remove the drain plug and drain the transmission.

Position a suitable drain pan under the transmission.

2. Clean and install the drain plug.

3. N ...

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A

new part with

the same part number must be installed if installation becomes necessary. ...

Trim Panel - Package Tray

Special Tool(s)

Torx Bit, Safety Belt Bolt

501-010 (T77L-2100-A)

Removal and Installation

1. Remove the screw and the coat hook.

2. NOTE: Inspect the shoulder safety belt guide cover for damage. If the

shoulder safety belt guide

cover is d ...