Ford Mustang (1999-2004) Service Manual: Evaporative Emissions (Description and Operation)

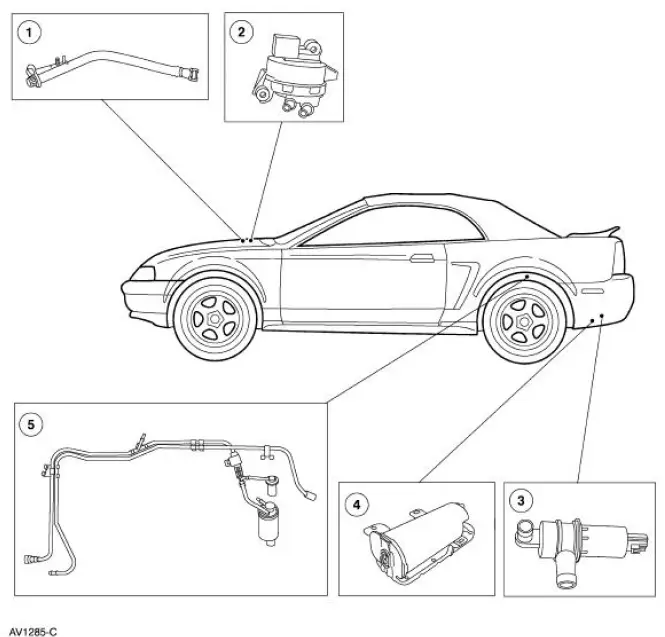

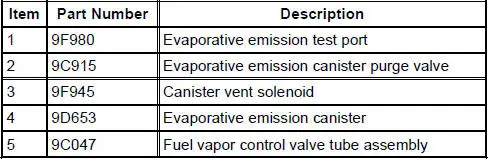

Component Location

The evaporative emission system:

- is equipped with an on-board refueling vapor recovery (ORVR) system.

- prevents hydrocarbon emissions from reaching the atmosphere.

- stores fuel vapors in the evaporative emission (EVAP) canister that are generated during vehicle operation or hot soak, or vehicle refueling, until they can be consumed by the engine.

- routes the stored fuel vapors to the engine during engine operation.

- is controlled by the powertrain control module (PCM) which uses various sensor inputs to calculate the desired amount of purge flow. The PCM regulates the purge flow, induced by the application of intake manifold vacuum, by varying the duty cycle applied to the EVAP canister purge valve.

- has an evaporative emission test port for test purposes.

The fuel vapors are routed:

- from the fuel tank through the fuel vapor control valve and fuel vapor vent valve.

- to the EVAP canister through a vapor line.

- to the engine when the EVAP canister purge valve is opened by the PCM.

The fuel tank pressure (FTP) sensor:

- monitors the pressure levels in the fuel tank.

- communicates the pressure reading to the PCM during the OBDII leak test.

- is located in-line above the fuel tank and is serviced as part of the fuel vapor control valve tube assembly.

The evaporative emission canister:

- is located in the left rear quarter panel.

- contains activated carbon.

- stores fuel vapor.

The fuel tank filler cap:

- relieves system pressure above 14 kPa (56.21 inches H 2 O).

- relieves system vacuum below 3.8 kPa (15.26 inches H 2 O).

The canister vent solenoid:

- is normally open.

- seals the EVAP system for the inspection and maintenance (I/M 240) test and OBDII leak and pressure tests.

- is mounted to the evaporative emission canister.

- is repaired as a separate item.

The evaporative emission (EVAP) canister purge valve:

- is normally closed.

- regulates purging of the EVAP canister.

- is controlled by the PCM.

- is located in the right front inner fender well.

The fuel vapor control valve tube assembly:

- consists of the fuel vapor control valve, fuel vapor vent valve and an in-line fuel tank pressure sensor.

- prevents suspended liquid fuel from being drawn into the evaporative emission canister along with the fuel vapors.

- returns the liquid to the fuel tank.

- includes a fresh air transfer tube routing fresh air between the canister vent solenoid hose and the fuel tank filler pipe assembly.

- requires two grommets to seal the fuel vapor control valve and fuel vapor vent valve to the fuel tank.

The evaporative emission (EVAP) system monitor:

- is a self-test strategy within the PCM, which tests the integrity of the EVAP system.

- monitors the EVAP system for leaks.

- monitors electronic EVAP components for irrationally high or low voltages.

- monitors for correct EVAP system operation.

- utilizes intake manifold vacuum to test the EVAP system and involves several stages.

The evaporative emission (EVAP) test port:

- is used to connect the Evaporative Emission System Leak Tester to the EVAP system.

- is located on the EVAP canister purge outlet tube near the EVAP canister purge valve.

Evaporative Emissions

Evaporative Emissions

General Specifications

Torque Specifications

...

Evaporative Emissions (Diagnosis and Testing)

Evaporative Emissions (Diagnosis and Testing)

Special Tool(s)

Evaporative Emission System

Leak Tester

310-F007 (134-00056) or

equivalent

Worldwide Diagnostic System

(WDS)

418-F224,

New Generation STAR (NGS)

Te ...

Other materials:

Drive Pinion Flange and Drive Pinion Seal

Special Tool(s)

2-Jaw Puller

205-D072 (D97L-4221-A) or

equivalent

Holding Fixture, Drive Pinion

Flange

205-126 (T78P-4851-A)

Installer, Drive Pinion Flange

205-002 (TOOL-4858-E) or

equivalent

...

Fuel consumption

Filling the Tank

The advertised capacity is the indicated capacity and the empty reserve

combined. Indicated capacity is the difference in the amount of fuel in a

full tank and a tank when the fuel gauge indicates empty. Empty reserve

is the amount of fuel in ...

Assembly

1. NOTE: Lubricate direct clutch piston inner seal and seal protector

with petroleum jelly.

Using the special tool, install the inner piston seal.

Install the seal with sealing lip facing down.

2. Install the clutch piston outer seal so that when the pis ...