Ford Mustang (1999-2004) Service Manual: Horn (Diagnosis and Testing)

Refer to Wiring Diagrams Cell 44 , Horns/Cigar Lighter for schematic and connector information.

Special Tool(s)

|

73 Digital Multimeter or equivalent 105-R0051 |

Inspection and Verification

1. Verify the customer concern by operating the horn (13832).

2. Visually inspect for obvious signs of mechanical and electrical damage.

Visual Inspection Chart

| Mechanical | Electrical |

|

|

3. If fault is not visually evident, determine the symptom and proceed to Symptom Chart.

Symptom Chart

| Condition | Possible Sources | Action |

|

|

|

|

|

|

Pinpoint Tests

PINPOINT TEST A: THE HORN DOES NOT SOUND

| Test Step | Result / Action to Take |

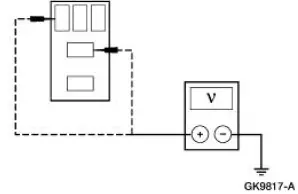

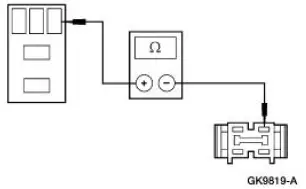

| A1 CHECK POWER SUPPLY TO HORN RELAY | Yes GO to A2 . No REPAIR the circuit in question. TEST the system for normal operation. |

|

|

| A2 CHECK HORN RELAY | Yes GO to A3 . No INSTALL a new horn relay. TEST the system for normal operation. |

|

|

| A3 CHECK HORN SWITCH SIGNAL TO HORN RELAY | Yes GO to A4 . No GO to A5 . |

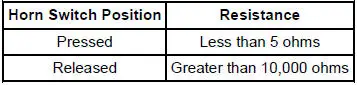

Horn Switch Position

|

|

| A4 CHECK WIRE BETWEEN HORN RELAY AND HORN | Yes INSTALL new horns. TEST the system for normal operation. No REPAIR the circuit. TEST the system for normal operation. |

|

|

| A5 CHECK WIRE BETWEEN HORN RELAY AND AIR BAG SLIDING CONTACT | Yes GO to A6 . No REPAIR the circuit. TEST the system for normal operation. |

|

|

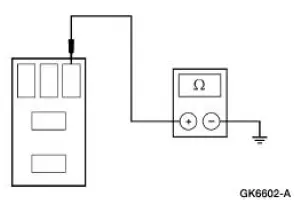

| A6 CHECK AIR BAG SLIDING CONTACT | Yes GO to A7 . No INSTALL a new air bag sliding contact. REFER to Section. TEST the system for normal operation. |

|

|

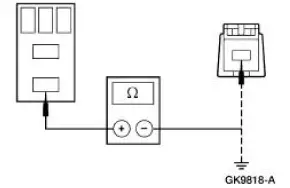

| A7 CHECK THE STEERING WHEEL SWITCH HARNESS | Yes INSTALL a new horn switch. REFER to Switch-Horn . TEST the system for normal operation. No INSTALL a new steering wheel switch harness. TEST the system for normal operation. |

|

PINPOINT TEST B: THE HORN SOUNDS CONTINUOUSLY

| Test Step | Result / Action to Take |

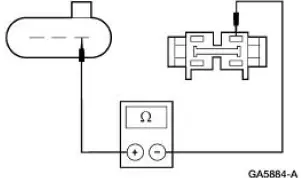

| B1 CHECK HORN CIRCUIT 1 (DB) | Yes REPAIR Circuit 1 (DB) for short to battery. TEST the system for normal operation. No GO to B2 . |

|

|

| B2 CHECK HORN RELAY | Yes REINSTALL the horn relay. GO to B3 . No INSTALL a new horn relay. TEST the system for normal operation. |

|

|

| B3 CHECK CIRCUIT 6 (YE/LG) | Yes GO to B4 . No RECONNECT the air bag sliding contact. GO to B5 . |

|

|

| B4 CHECK GEM INPUT | Yes REPAIR Circuit 6 (YE/LG). TEST the system for normal operation. No INSTALL a new GEM; REFER to Section. TEST the system for normal operation. |

|

|

| B5 CHECK THE AIR BAG SLIDING CONTACT | Yes INSTALL a new air bag sliding contact. REFER to Section. TEST the system for normal operation. No GO to B6 . |

|

|

| B6 CHECK STEERING WHEEL SWITCH HARNESS | Yes INSTALL a new horn switch. REFER to Switch- Horn . TEST the system for normal operation. No INSTALL a new steering wheel switch harness. TEST the system for normal operation. |

|

Horn

Horn

Torque Specifications

Horn

The horn system consists of the following:

dual horns (one high-pitched, one low-pitched)

horn switch (located underneath the driver side air bag module

[043 ...

Switch - Horn

Switch - Horn

Removal

1. Remove the driver side air bag module (043B13). Refer to Section.

2. Remove the switches.

1. Disconnect the horn wire from the switches.

2. Remove the horn switch screws and ...

Other materials:

Fuel Vapor Control Tube Assembly Valve

Removal and Installation

1. Remove the fuel tank. For additional information, refer to

Section.

2. Remove the retainers.

3. NOTE: The fuel vapor vent valve, fuel vapor control valve and the

in-line fuel tank pressure

sensor are repaired as a fuel va ...

Gearshift Rail and Fork

Disassembly and Assembly

1. Using a 5/32-inch drift and a hammer, remove and discard the split pin.

Slide the shift fork from

the shift rail.

2. Remove the gearshift fork inserts.

3. CAUTION: Support the shift rail to prevent damage to the parts.

Positio ...

Pinpoint Tests

CAUTION: Before removing and installing the generic electronic

module (GEM) or its

connectors, disconnect the battery. Failure to follow this caution will

result in the GEM storing

many erroneous DTCs, and it may exhibit erratic operation after

in ...