Ford Mustang (1999-2004) Service Manual: Input Shaft and Bearing

Special Tool(s)

|

Plate, Bearing/Oil Seal 205-090 (T75L-1165-B) |

|

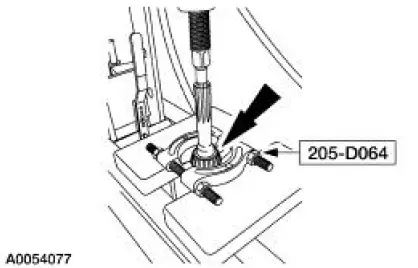

Puller, Bearing 205-D064 (D84L-1123-A) |

|

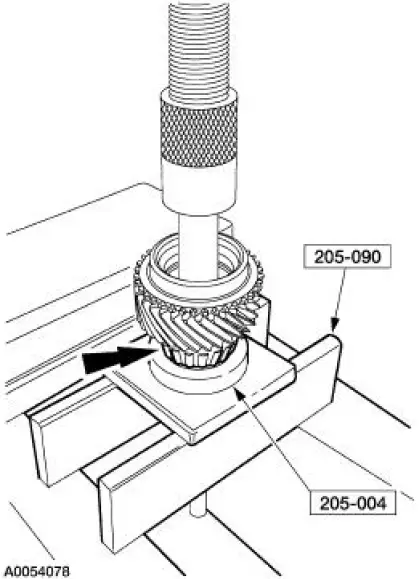

Installer, Drive Pinion Bearing Cone 205-004 (T53T-4621-B) |

|

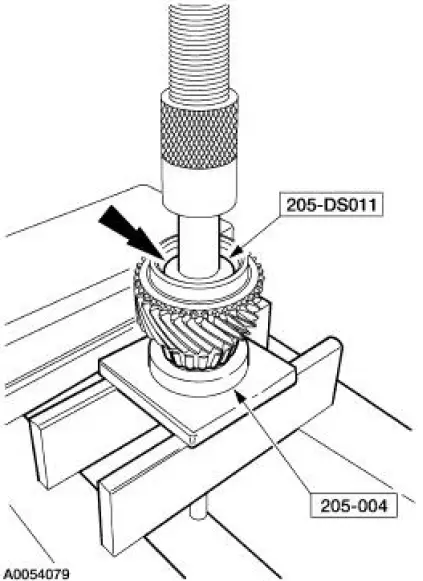

Adapter Set, Step Plate 205-DS011 (D80L-630-A) |

|

Universal Puller Set 303-DS005 (D80L-100-A) |

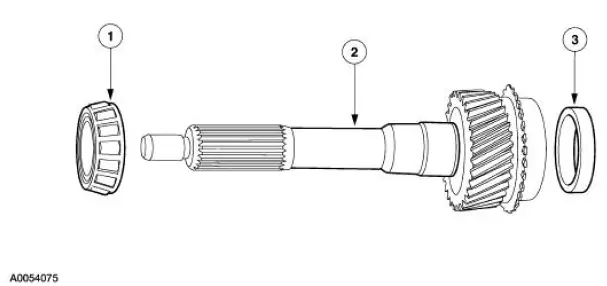

Disassembly and Assembly

1. CAUTION: Use a vise with brass jaws or wood blocks.

Secure the input shaft in a vise. Using the special tools and a slide hammer, remove the input shaft bearing cup.

- Inspect the cup for wear or damage. Install a new bearing cup and bearing as necessary.

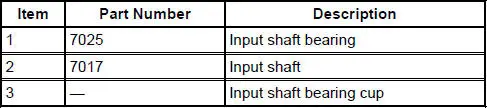

2. Using the special tool and a press, remove the input shaft front bearing.

3. Inspect the input shaft and bearing for wear or damage. Install new components as necessary.

4. Using the special tools and a press, install a new input shaft bearing.

- Lubricate the bearing with petroleum jelly.

5. Using a suitable driver and the press, install the input shaft bearing cup.

- Lubricate the bearing cup with petroleum jelly.

Transmission (Disassembly)

Transmission (Disassembly)

Special Tool(s)

Holding Fixture, Transmission

307-003 (T57L-500-B)

Puller, Bearing

205-D064 (D84L-1123-A)

2 or 3 Jaw Puller

205-D027 (D80L-1013-A)

...

Output Shaft

Output Shaft

Special Tool(s)

Puller, Bearing

205-D064 (D84L-1123-A)

Adapter for 303-224 (Handle)

205-153 (T80T-4000-W)

Installer, Output Shaft Rear

Bearing

308-401

...

Other materials:

Component Tests

Pressure Test

1. Turn the engine OFF.

2. WARNING: Never remove the pressure relief cap under any conditions

while the

engine is operating. Failure to follow these instructions could result in damage

to the

cooling system or engine and/or personal injury. To ...

Engine coolant check

Checking the Engine Coolant

The concentration and level of engine coolant should be checked at the

intervals listed in Scheduled Maintenance Information.

Note: Make sure that the level is at the FULL COLD level or within the

COLD FILL RANGE in the coolant res ...

Index Card

Place an index card or a piece of paper between the weatherstrip and the

sealing surface, then close

the door. Slowly withdraw the index card or paper after the door is closed and

check the amount of

pressure on the weatherstrip. There should be a medium amo ...