Ford Mustang (1999-2004) Service Manual: Installation

NOTE: Do not use a fiber disc to clean the surfaces. Fibers from the disc can get into the oil pan and oil and clog the oil bypass valve.

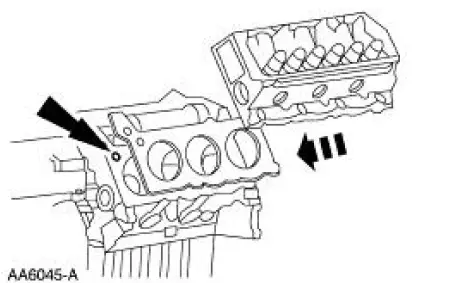

1. Clean and inspect the cylinder head for flatness. 2. Install a new head gasket on the cylinder block with the small hole to the front of the engine and position the cylinder head.

3. CAUTION: Always use new bolts.

NOTE: Lubricate the bolts with clean engine oil.

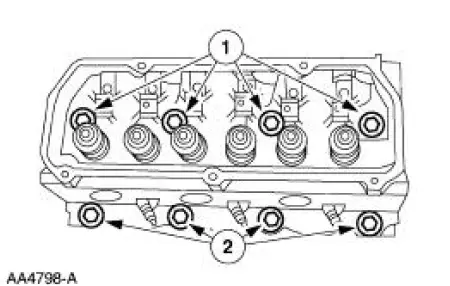

Install new bolts. Refer to the location note made during removal and make sure the bolts are installed the correct location.

1. Install the new long bolts.

2. Install the new short bolts.

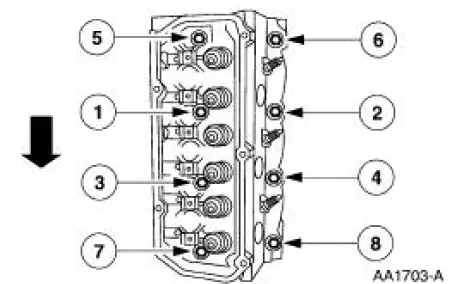

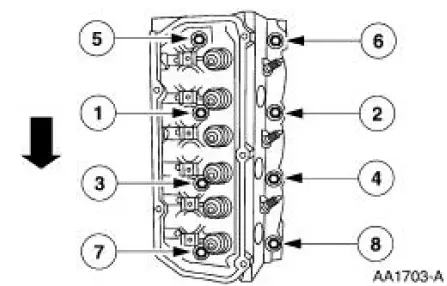

4. Tighten the bolts in three stages in the sequence shown.

- Stage 1: Tighten to 20 Nm (15 lb-ft).

- Stage 2: Tighten to 40 Nm (30 lb-ft).

- Stage 3: Tighten to 50 Nm (37 lb-ft).

5. CAUTION: Do not loosen all of the bolts at one time. Each bolt must be loosened and final-tightened prior to working on the next bolt in the sequence.

NOTE: The short bolts are numbered 2, 4, 6 and 8 and the long bolts are numbered 1, 3, 5 and 7.

Loosen, then tighten the bolts in the sequence shown:

- Tighten short bolts to 25 Nm (18 lb-ft), then tighten an additional 180 degrees.

- Tighten long bolts to 45 Nm (33 lb-ft), then tighten an additional 180 degrees.

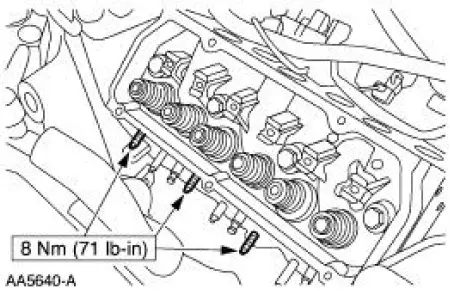

6. Install the three studs.

7. Install the bracket and bolts.

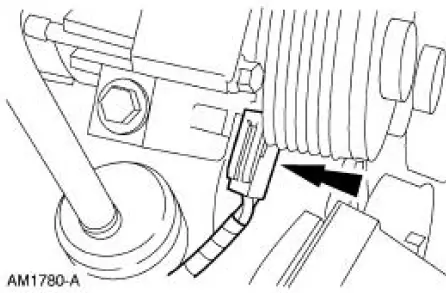

8. Connect the A/C compressor clutch electrical connector.

9. Connect the A/C manifold and tube assembly.

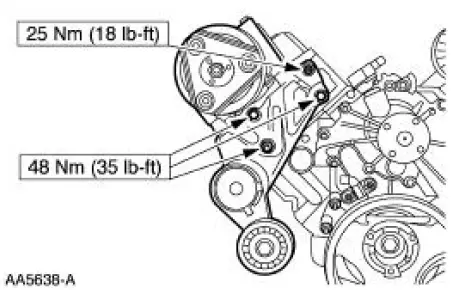

10. Install the accessory drive belt.

11. Install the push rods. For additional information, refer to Push Rod in this section.

12. Install the lower intake manifold. For additional information, refer to Lower Intake Manifold in this section.

13. Install the RH exhaust manifold. For additional information, refer to Exhaust Manifold RH in this section.

14. Connect the battery ground cable.

15. CAUTION: Correct cooling system bleeding is critical for correct engine cooling.

Fill and bleed the engine cooling system.

16. Recharge the A/C refrigerant system.

Removal

Removal

1. Disconnect the battery negative cable.

2. Drain the engine cooling system.

3. Remove the RH exhaust manifold. For additional information, refer to Exhaust

Manifold RH in

this section.

4. Remo ...

Oil Level Indicator and Tube

Oil Level Indicator and Tube

Removal and Installation

1. Remove the oil level indicator tube (6754).

Remove the bolt.

Remove the oil level indicator tube.

Remove and discard the oil level indicator tube O-ring.

2. To ...

Other materials:

Exterior Lighting

Torque Specifications

Exterior Lighting

The exterior lighting system consists of the following components:

headlamps (13008)

parking lamps

rear lamps (13404)

high mounted stoplamp

license lamps

front turn lamps

reversing lamps

fog ...

Halfshaft Joint

Special Tool(s)

Driver

205-199 (T83T-3132-A1)

Hub Bearing Cup Replacer

205-147 (T80T-4000-P)

Sensing Ring Replacer

206-041 (T89P-20202-A)

Disassembly

1. CAUTION: Do not disassemble the halfshaft assembly. Install a new

assem ...

Switch - Exterior Rear View Mirror Control

Removal

1. CAUTION: Use a shop towel or similar material between the tool

and the front door

trim panel or damage to the front door trim panel may occur.

Position the window regulator switch plate aside.

1. Pull at service notch.

2. Lift to release ...