Ford Mustang (1999-2004) Service Manual: Installation

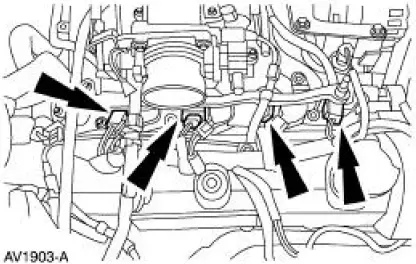

1. NOTE: The LH side is shown, and the RH is similar.

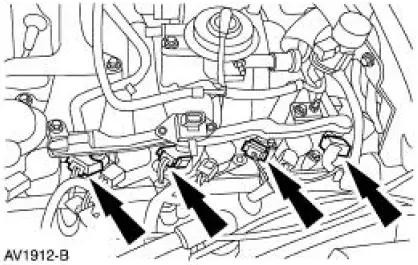

Install the supply manifold and tighten the four bolts.

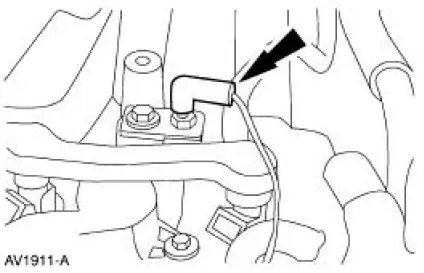

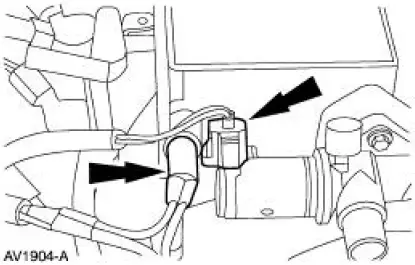

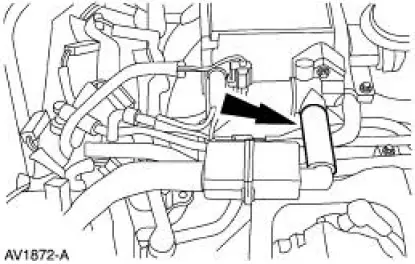

2. Connect the EGR vacuum line.

3. Install the EGR to exhaust manifold tube. For additional information, refer to Section.

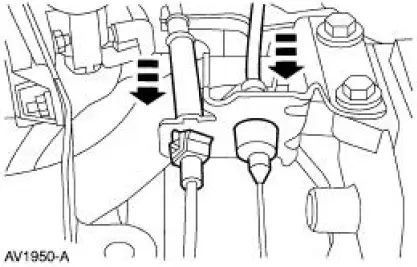

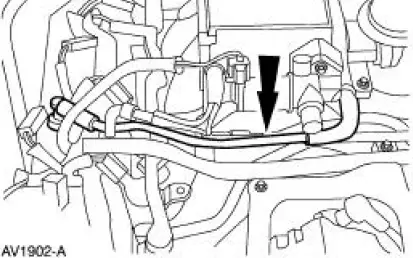

4. NOTE: The engine is removed for clarity.

Position the EVR bracket and tighten the bolts.

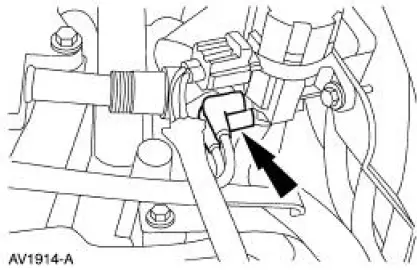

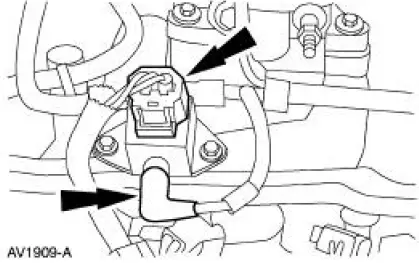

5. Connect the EVR solenoid vacuum lines.

6. Connect the LH fuel injector electrical connectors.

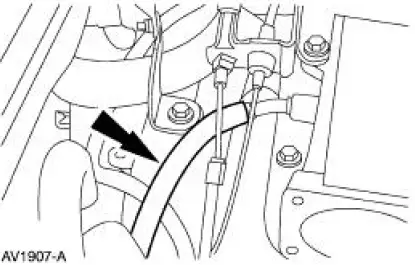

7. Connect the ground wire.

8. Connect the fuel pressure sensor electrical connector and the vacuum hose.

9. NOTE: Make sure the locking clips are fully engaged into the bracket.

Reposition the accelerator cable and the speed control cable (if equipped) and install the cables into the bracket.

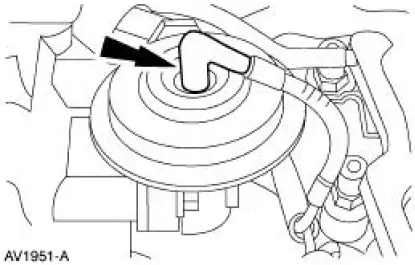

10. Connect the hose.

11. Connect the IAC electrical connector and install the main chassis vacuum hose.

12. Connect the four RH fuel injector electrical connectors.

13. Connect the PCV hose.

14. Position the IAC hose and connect the hose.

15. Install the throttle body.

16. Connect the fuel line.

17. Connect the air cleaner outlet tube.

18. Connect the battery ground cable.

Removal

Removal

WARNING: Do not smoke or carry lighted tobacco or open flame of any

type when

working on or near any fuel related components. Highly flammable mixtures are

always present

and may be ignited. Failure ...

Fuel Charging and Controls - Cobra 4.6L (4V)

Fuel Charging and Controls - Cobra 4.6L (4V)

General Specifications

Torque Specifications

...

Other materials:

Heated seats

WARNING: Persons who are unable to feel pain to the skin

because of advanced age, chronic illness, diabetes, spinal cord

injury, medication, alcohol use, exhaustion, or other physical conditions,

must exercise care when using the seat heater. The seat heater m ...

Cleaning the instrument panel and instrument cluster lens

WARNING: Do not use chemical solvents or strong detergents

when cleaning the steering wheel or instrument panel to avoid

contamination of the airbag system.

Clean the instrument panel and cluster lens with a clean, damp, white,

cotton cloth, then use a clean a ...

Installation

1. Overlay the new rear window glass assembly over the old rear

window glass assembly and

transpose the markings with a grease pencil.

2. Center the V-notch on the new rear window glass assembly to the

center mark on the top of the

number four bow ...