Ford Mustang (1999-2004) Service Manual: Motor - Windshield Wiper

Removal

CAUTION: The internal permanent magnets used in the windshield wiper motor are made of a glass-like material. To avoid damaging the magnets, do not strike the motor with a hammer or any other object.

NOTE: The windshield wiper motor is not a repairable item. If worn or damaged, install a new wiper motor.

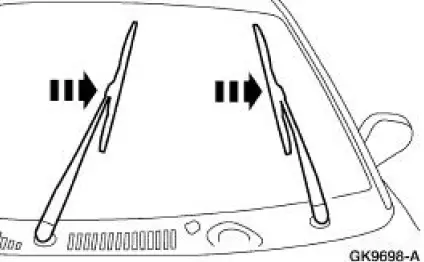

1. Park the windshield wipers in the full upright position. This will allow for easy access to the retaining clip on the wiper motor output shaft.

2. Remove the cowl top vent panels.

3. Disconnect the negative battery cable.

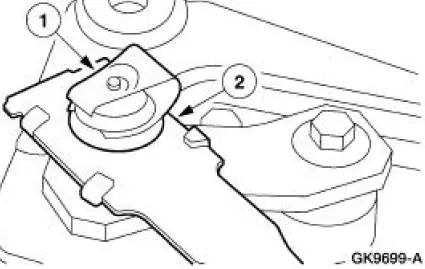

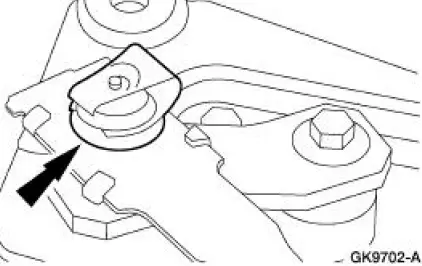

4. Disconnect the mounting arm and pivot shaft linkage from the wiper motor output shaft.

1. Remove the clip.

2. Disconnect the mounting arm and pivot shaft linkage.

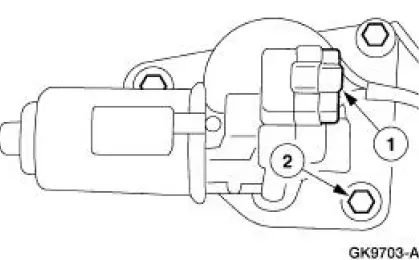

5. Remove the wiper motor.

1. Disconnect the electrical connector.

2. Remove the bolts.

Installation

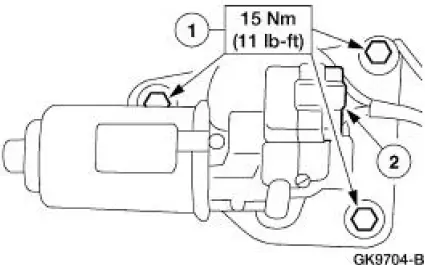

1. NOTE: Install the retaining clip onto the mounting arm and pivot shaft linkage prior to the installation of the wiper motor.

Install the wiper motor

1. Install the bolts.

2. Connect the electrical connector.

2. Snap the mounting arm and pivot shaft linkage onto the wiper motor output shaft.

3. NOTE: When the battery is disconnected and reconnected, some abnormal drive symptoms may occur while the vehicle relearns its adaptive strategy. The vehicle may need to be driven 16 km (10 miles) or more to relearn the strategy.

Reconnect the negative battery cable.

4. Cycle the wiper motor to the park position.

5. Install the cowl top vent panels.

- Adjust pivot arms as necessary. Refer to Wiper Blade and Pivot Arm Adjustment .

Mounting Arm and Pivot Shaft

Mounting Arm and Pivot Shaft

Removal

1. Park the windshield wipers in the full upright position. This will

allow for easy access to the

retaining clip on the wiper motor output shaft.

2. Remove the cowl top vent panels.

...

Washer Pump

Washer Pump

Removal

1. Remove the LF wheel and tire. Refer to Section.

2. Position the front portion of the LF inner splash shield aside.

3. WARNING: Windshield washer solution contains methanol, which is ...

Other materials:

Car2U® home automation system

WARNING: Make sure that the garage door and security device

are free from obstruction when you are programming. Do not

program the system with the vehicle in the garage.

WARNING: Do not use the system with any garage door opener

that does not have the safety s ...

Removal

CAUTION: Suspension fasteners are critical parts because they affect

performance of vital

components and systems and their failure can result in major service expense. A

new part with

the same part number must be installed if installation becomes necessary. ...

Cylinder Head - Distortion

Special Tool(s)

Straight Edge

303-D039 (D83L-4201-A) or

equivalent

1. Use a straight edge and a feeler gauge to inspect the cylinder head for

flatness. If the cylinder

head is distorted, install a new cylinder head.

Cylinder Bore -Cleaning ...